32 Harley Crescent Condell Park NSW, 2200 Australia

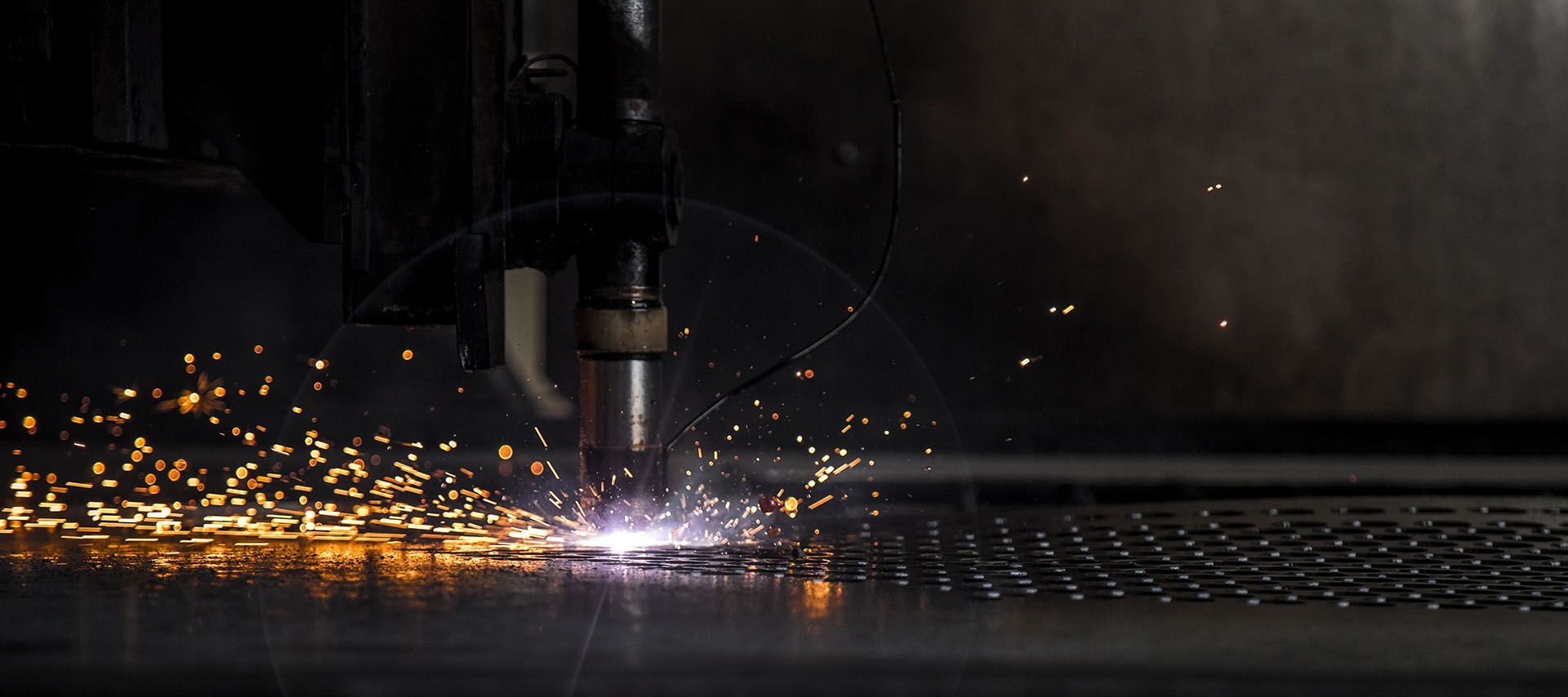

TRUMPF Introduces Truprint 3000, a Laser Metal Fusion Metal 3D Printer

EuroBLECH 2016, the 24th International Sheet Metal Working Technology Exhibition, took place last month in Germany. The event showcased a variety of machines, with the 3D printing process heavily dominating the occasion.

The event welcomed over 60,000 visitors from more than 100 different countries to get an overview of the latest trends and technical developments in sheet metal, along with providing the opportunity to invest in new production equipment.

TRUMPF, renowned for being one of the world’s most innovative and high-tech companies in the industry, showcased the Truprint 3000. This new LMF 3D printer is used for the laser metal fusion process.

In the 3D printing process, known as additive manufacturing, components are produced by means of powder and laser light. Using a 3-D model, they are built up layer by layer.

The universal medium-format machine is aimed at industrial production of complex metal parts using the LMF process. The user interface has been optimised for simplified, user-friendly touch screen control, while the machine finds applications in a wide range of industries – from medical to aerospace.

TRUMPF believes that the Truprint 3000 is well equipped for series production due to its reproducible power and high print quality.

Michael White from Hygrade explains “TRUMPF’s leadership in technology enables small companies like us to be competitive in the Manufacturing Industry. A current example is our new fiber laser with innovative cutting methods such as “Brightline” which gives us an advantage over all competitors.”

Get in touch

to find out how we can help you with your project.

RECENT POSTS