32 Harley Crescent Condell Park NSW, 2200 Australia

HYGRADE LASER PROFILING

Pipe & Tube Laser Cutting Tamworth

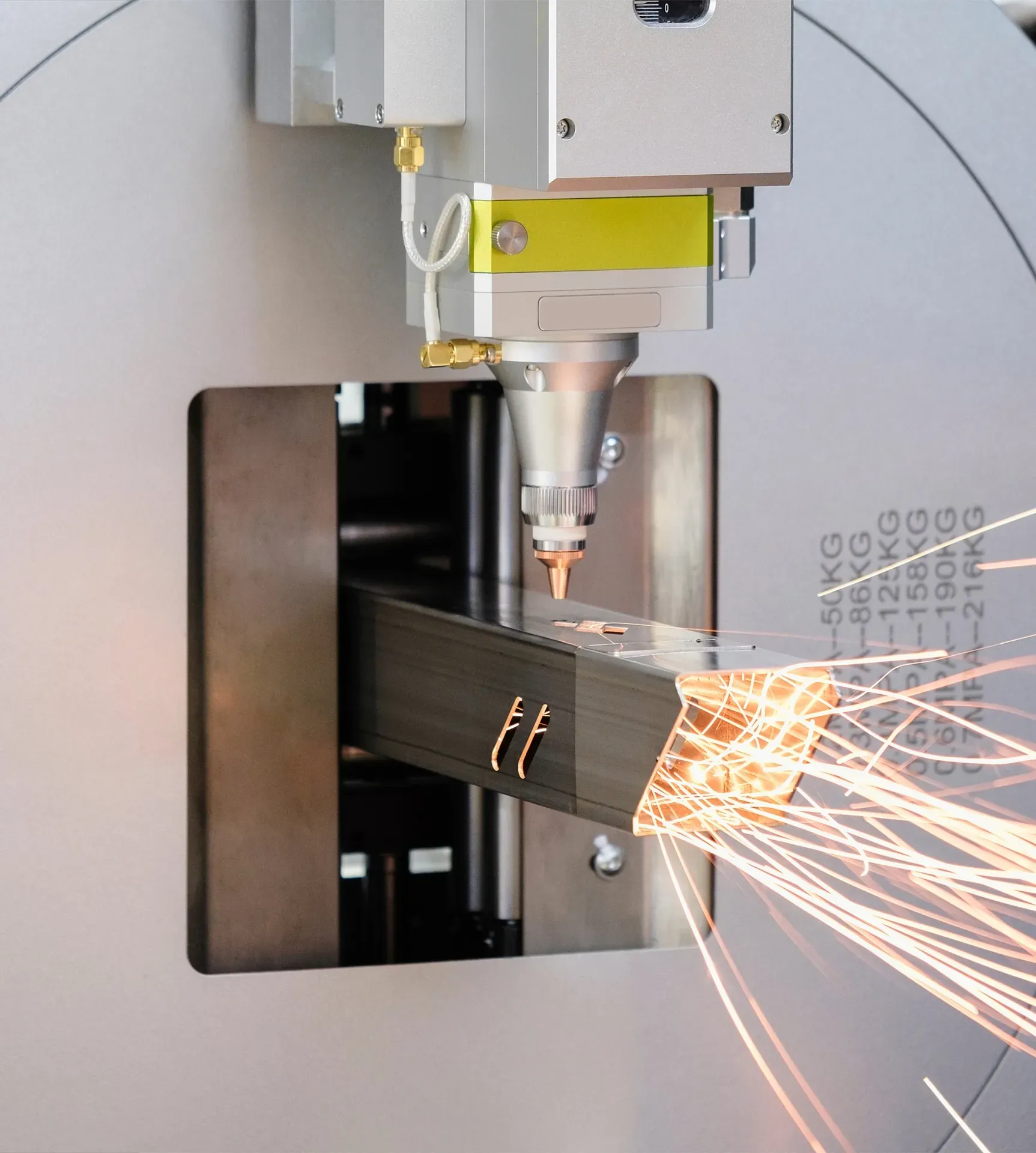

Hygrade Laser Profiling provides advanced pipe and tube laser cutting services, producing accurately cut components for a range of industries. Our cutting-edge laser technology ensures clean, sharp, and accurate cuts, making it the ideal solution for businesses that require efficiency and consistency in their production processes.

We serve Tamworth and surrounding areas, helping businesses streamline manufacturing and enhance productivity. Our high-precision cutting process guarantees consistent, high-quality results, whether for custom prototypes or large-scale production runs.

DIFFERENT TECHNOLOGY WE USE

Our Trumpf L3050 5kW, fitted with a Trumpf RotoLas device, allows for precise laser cutting of tubes and box sections. It operates on both horizontal and vertical axes, making it well-suited for complex shapes and intricate geometries. With a maximum cutting capacity of 414mm, it ensures consistent and highly accurate results across various applications.

For more specialised tube processing, our Trumpf TruLaser 3000 Fiber delivers high-speed laser cutting. Featuring RapidCut technology, it enhances cutting efficiency and accuracy, allowing for fast processing without compromising on quality. This advanced system supports seamless production workflows, improving turnaround times while maintaining exacting standards.

Trumpf L3050 5kw

- Tube Processing (Rotolas).

- 1500mm x 3000mm Cutting Area.

Trumpf TruLaser Tube 3000

- RapidCut feature for quick and optimal results.

- Maximum finished part length of up to 6.5 m.

OUR ADVANCED PIPE & TUBE LASER CUTTING SERVICES IN TAMWORTH

When it comes to accurate and efficient pipe and tube laser cutting, businesses in Tamworth require precision, speed, and consistency. Our state-of-the-art Trumpf laser systems transform raw tubing into precisely cut components, ready for seamless assembly.

Our advanced laser technology handles intricate shapes and complex geometries with ease, working with mild steel, stainless steel, and aluminium. By minimising material waste and reducing manual handling, we enhance efficiency, accuracy, and turnaround times. Every cut meets rigorous quality standards, providing consistent, high-precision results for small prototypes and large-scale production runs alike.

WHY CHOOSE LASER CUTTING FOR PIPES & TUBES

Conventional cutting techniques often lack precision, slow down production, and generate excessive material waste. Laser cutting offers a faster, more accurate, and cost-effective alternative, as it delivers clean, precise cuts with minimal waste.

Exceptional Precision

Achieves highly detailed cuts with tight tolerances, even on intricate and complex designs.

Increased Efficiency

High-speed laser systems with automated loading streamline production and reduce lead times.

Broad Material Compatibility

Works with round, square, rectangular, and custom-profile tubes across various metal types and thicknesses.

Reduced Waste & Lower Costs

Advanced laser technology optimises material usage, cutting down on scrap and reducing overall expenses.

Smooth, Ready-to-Use Finishes

Produces clean, burr-free edges, eliminating the need for additional processing or refinishing.

Ideal for

Bulk Manufacturing

Automation ensures consistent quality while reducing costs for large production runs.

Industries that require precision, speed, and repeatability choose laser cutting because it streamlines manufacturing, enhances product quality, and delivers dependable results at any scale.

APPLICATIONS OF TUBE & PIPE LASER CUTTING

Many industries depend on laser cutting technology for pipe and tubing fabrication, benefiting from its precision, speed, and ability to produce clean, consistent cuts. This advanced cutting method reduces material waste, eliminates unnecessary processing steps, and improves overall production efficiency. Some of the most common applications include:

Automotive & Transport

Cutting and shaping roll cages, exhaust pipes, chassis components, and structural tubing.

Agricultural Machinery

Precision-cut tubing for irrigation, harvesting, and tractor assemblies.

Construction & Structural Engineering

Tubing solutions for frameworks, steel beams, and infrastructure support.

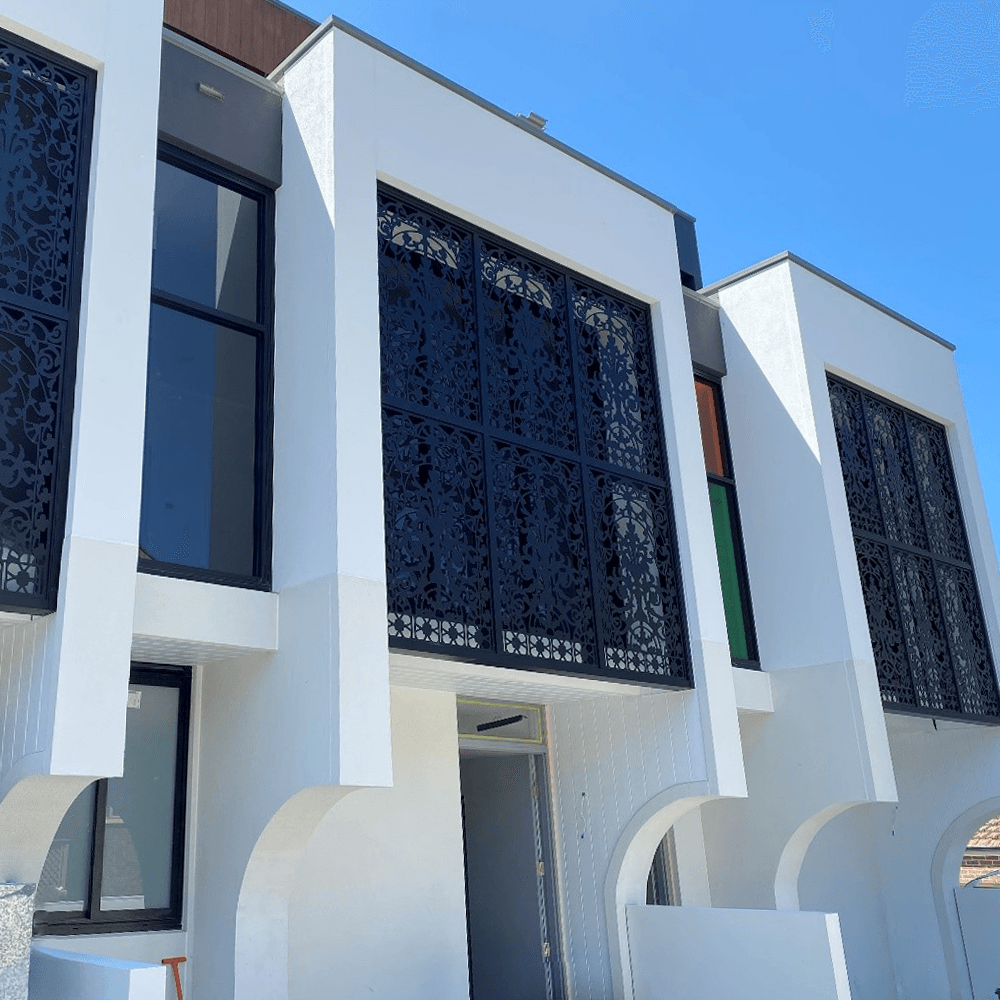

Architectural & Furniture Design

Intricate laser cutting for balustrades, decorative elements, and furniture fabrication.

Heavy Machinery & Equipment

Custom-cut tubing for supports, brackets, and machine frames.

Mass Production & Manufacturing

Reliable, repeatable cutting for industrial-scale fabrication.

PIPE & TUBE LASER CUTTING FAQS

What is pipe and tube laser cutting?

Pipe and tube laser cutting is a highly accurate cutting method that uses a focused laser beam to cut through metal tubing with precision and efficiency. This process enables clean edges, intricate designs, and minimal material waste, making it a reliable solution for industries that require consistent, high-quality components.

What types of pipes and tubes can be laser cut?

We can process round, square, rectangular, and custom-shaped tubes made from materials such as mild steel, stainless steel, and aluminium.

How does laser cutting compare to traditional cutting methods?

Unlike conventional methods, laser cutting provides unmatched precision, smooth edges, and faster processing times. It eliminates the need for secondary finishing, reduces material waste, and efficiently cuts complex geometries that traditional techniques struggle with.

What are the size and thickness capabilities of your laser tube cutting machines?

Our Trumpf L3050 5kW can cut complex shapes with a maximum envelope size of 414mm. The Trumpf TruLaser Tube 3000 Fiber handles finished parts up to 6.5m in length. Both fiber laser tube cutting machines provide high-precision results.

Can you assist with component design and modifications?

Yes! We offer design refinement, modifications, and prototyping to ensure components are optimised for laser cutting. Whether fine-tuning an existing design or creating something new, our team provides expert support.

Do you offer services beyond laser cutting?

Yes! We also offer bending, rolling, machining, welding, and fastening solutions. By handling everything in-house, we reduce project lead times and maintain strict quality control across all services.

How long does laser cutting take?

Turnaround times vary depending on order complexity and quantity, but our automated systems and high-speed laser technology allow us to process jobs quickly and efficiently. Contact us for an estimated completion time for your project.

Can you handle large production runs?

Yes! Our laser cutting technology is built for both one-off prototypes and large-scale production. We ensure precision, consistency, and repeatability, no matter the project size.

Do laser-cut tubes require additional finishing?

No, laser-cut tubes have clean, smooth edges right from the cutting process. Deburring or extra finishing is rarely needed, which reduces processing time and cost.

Where do you offer your services?

We are based in Sydney and provide laser cutting services to businesses in Tamworth and across NSW. If you’re unsure whether we operate in your area, get in touch with our team.

How can I request a quote?

Click "Get a Quote", submit your project details, and our team will review your requirements. We’ll provide you with pricing, lead times, and any additional recommendations.

Are there any materials you do not laser cut?

Yes, we do not cut plastic, timber, or other non-metallic materials. Our services focus on metal cutting, including mild steel, stainless steel, aluminium, brass, and copper. If you're unsure about material compatibility, reach out to us for expert advice.