32 Harley Crescent Condell Park NSW, 2200 Australia

HYGRADE LASER PROFILING

Pipe & Tube Laser Cutting Sydney

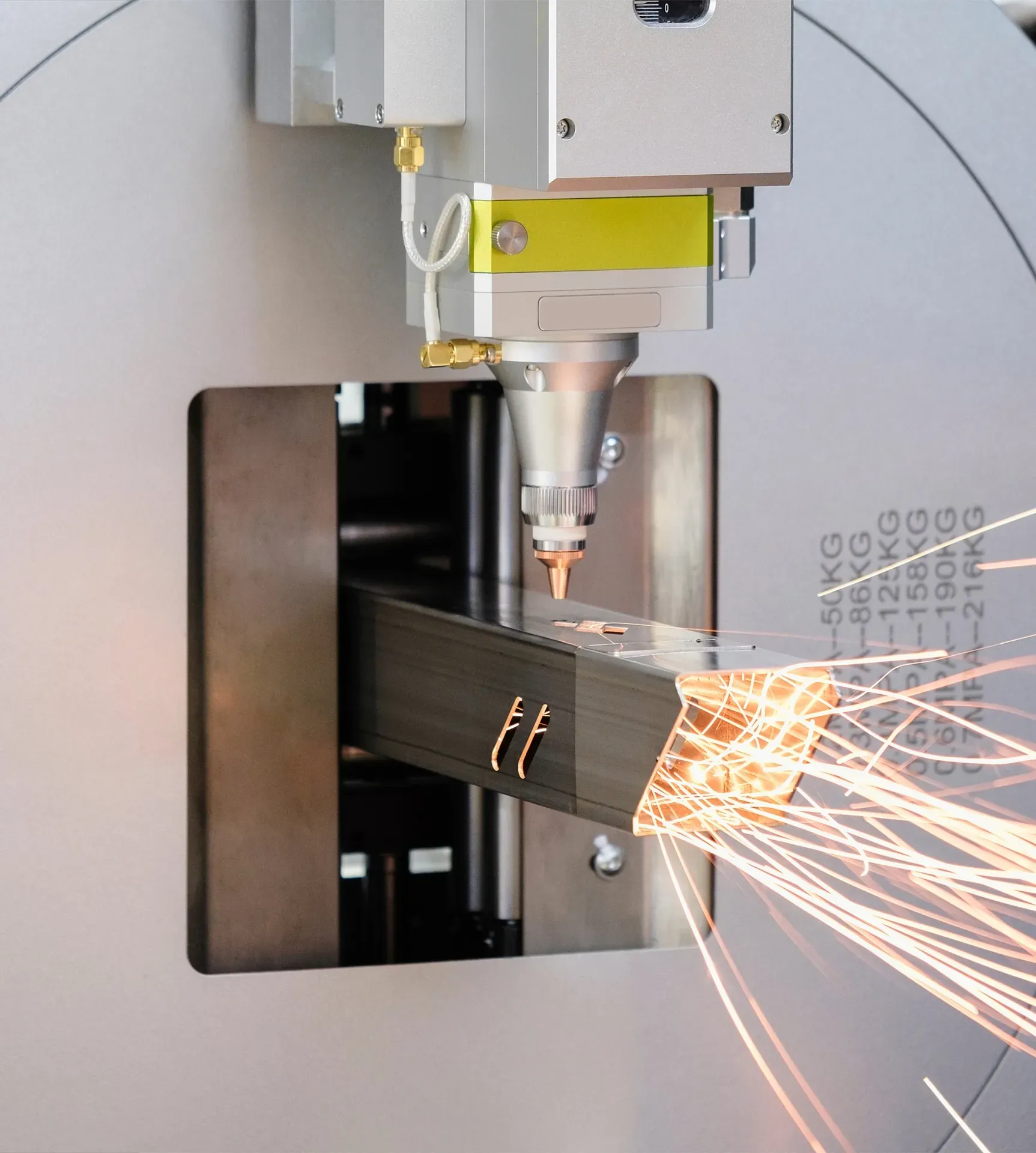

Our advanced pipe and tube laser cutting technology streamlines production by transforming raw tubing into precisely cut components, ready for final assembly. With high-speed automation and precision, our laser cutters handle intricate designs and complex geometries with ease, reducing manual labour and improving efficiency.

DIFFERENT TECHNOLOGY WE USE

Our Trumpf L3050 5kW comes with a Trumpf RotoLas device that enables accurate laser tube and box section cutting on any horizontal or vertical axis. It can laser cut complex shapes up to a maximum envelope size of 414mm.

For advanced tube processing, our Trumpf TruLaser 3000 Fiber provides high-precision results. With RapidCut technology, it delivers fast and accurate laser tube cutting, maintaining efficiency without compromising quality.

Trumpf L3050 5kw

- Tube Processing (Rotolas).

- 1500mm x 3000mm Cutting Area.

Trumpf TruLaser Tube 3000

- RapidCut feature for quick and optimal results.

- Maximum finished part length of up to 6.5 m.

OUR ADVANCED PIPE & TUBE LASER CUTTING SERVICES

At Hygrade Laser Profiling, we specialise in tube and pipe laser cutting to meet the needs of industries requiring accuracy, speed, and efficiency. Our advanced laser technology allows us to transform raw tubing into high-quality, ready-to-assemble components.

We use state-of-the-art Trumpf laser systems to handle intricate cuts, complex geometries, and various materials. Whether it’s mild steel, stainless steel, aluminium, or other metals, our cutting solutions offer tight tolerances, smooth finishes, and minimal waste.

With our automated loading and cutting process, we reduce manual handling, resulting in faster turnaround times without compromising on quality. From one-off prototypes to large-scale production runs, our laser tube cutting services are capable of delivering reliable and repeatable results for all projects.

WHY CHOOSE LASER CUTTING FOR PIPES & TUBES

Traditional cutting methods can be slow, inconsistent, and prone to material waste. Laser tube cutting offers a smarter, more efficient solution. Here’s why:

Unmatched Precision

Achieve tight tolerances and detailed cuts, no matter how complex the design.

Speed & Efficiency

High-speed cutting with automated loading allows for maximum productivity.

Versatility

Suitable for round, square, rectangular, and custom-shaped tubes in various materials and thicknesses.

Minimal Material Waste

Clean, precise cuts mean less scrap and better cost efficiency.

Reduced Secondary Processing

No need for extra deburring or finishing — laser-cut edges are smooth and ready to go.

Cost-Effective

for Large Runs

Automated processes lower labour costs and improve repeatability for bulk orders.

Whether you need structural components, automotive parts, or custom-fabricated tubing, laser cutting delivers superior results with less hassle.

APPLICATIONS OF TUBE & PIPE LASER CUTTING

Pipe and tube laser cutting enhances efficiency, precision, and production quality across multiple industries. Some of its key applications include:

Automotive & Transport

Fabrication of chassis components, roll cages, exhaust systems, and structural tubing for vehicles.

Agricultural Machinery

Precision-cut tubing for irrigation systems, harvesting equipment, and tractor components to improve durability and performance.

Structural Steel & Frameworks

Cut-to-size tubing for construction, engineering, and infrastructure projects.

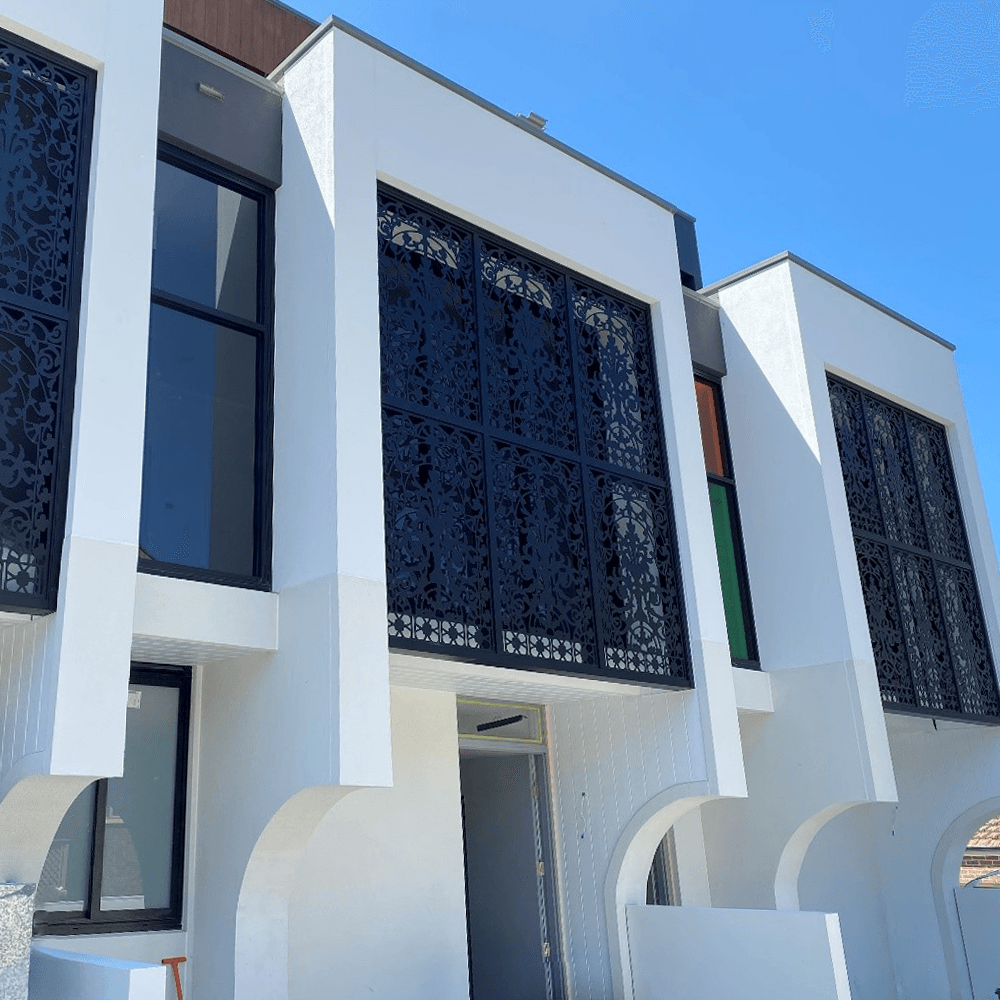

Furniture & Architectural Designs

High-accuracy cuts for balustrades, decorative metalwork, and modern furniture.

Industrial Equipment & Machinery

Fabrication of brackets, supports, and heavy-duty machine components.

Manufacturing & Processing

Reliable, repeatable cutting for OEM parts and large-scale industrial fabrication.

PIPE & TUBE LASER CUTTING FAQS

What is pipe and tube laser cutting?

Pipe and tube laser cutting is a precision cutting method that uses high-powered lasers to cut through metal tubing with accuracy and efficiency. It allows for intricate designs, smooth finishes, and minimal material waste.

What types of pipes and tubes can be laser cut?

We can laser cut round, square, rectangular, and custom-shaped tubes made from materials such as mild steel, stainless steel, and aluminium.

What are the benefits of laser cutting over traditional methods?

Laser cutting offers higher precision, faster production times, reduced material waste, and the ability to handle complex geometries that traditional cutting methods may struggle with.

What are the size and thickness capabilities of your laser tube cutting machines?

Our Trumpf L3050 5kW can cut complex shapes with a maximum envelope size of 414mm. The Trumpf TruLaser Tube 3000 Fiber handles finished parts up to 6.5m in length. Both fiber laser tube cutting machines provide high-precision results.

Can you design or modify components for tube and pipe laser cutting?

Yes! Our team can assist with design, modifications, and prototyping to optimise your components for laser cutting and manufacturing.

Do you offer additional services beyond laser cutting?

Yes! We are a one-stop shop for metal fabrication. Our services include bending, rolling, machining, welding, fixings, and fasteners, so we can complete your project beyond just laser cutting.

How fast is your turnaround time?

Turnaround times are highly dependent on the project’s complexity and volume, but our automated processes and high-speed lasers allow us to complete jobs efficiently. Contact us for an estimated timeframe.

Can you handle high-volume production?

Yes! Our automated laser cutting technology is well-suited for both small-batch and large-scale production runs. It ensures consistency and maintains high-quality standards across all parts.

Do laser-cut tubes require additional finishing?

No, the edges of laser-cut tubes are smooth and precise. This reduces or eliminates the need for secondary finishing like deburring.

Where do you offer your services?

We are based in Sydney and serve businesses across NSW and surrounding regions, including Wollongong, Central Coast, Goulburn, Canberra, Newcastle, Marulan, and Penrith.

How do I get a quote for my project?

Simply click “Request a Quote”, provide your project details, and our team will get back to you to discuss your project.

What materials do you NOT laser cut?

We do not laser cut plastic, timber, or other non-metallic materials. Our laser cutting services are focused on metals such as mild steel, stainless steel, aluminium, brass, and copper. If you're unsure whether your material is suitable for our fiber laser cutting machine, feel free to contact us.