32 Harley Crescent Condell Park NSW, 2200 Australia

HYGRADE LASER PROFILING

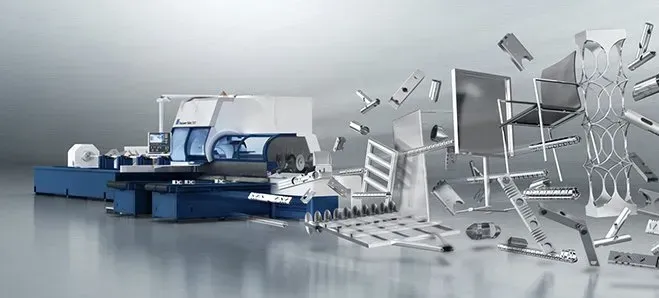

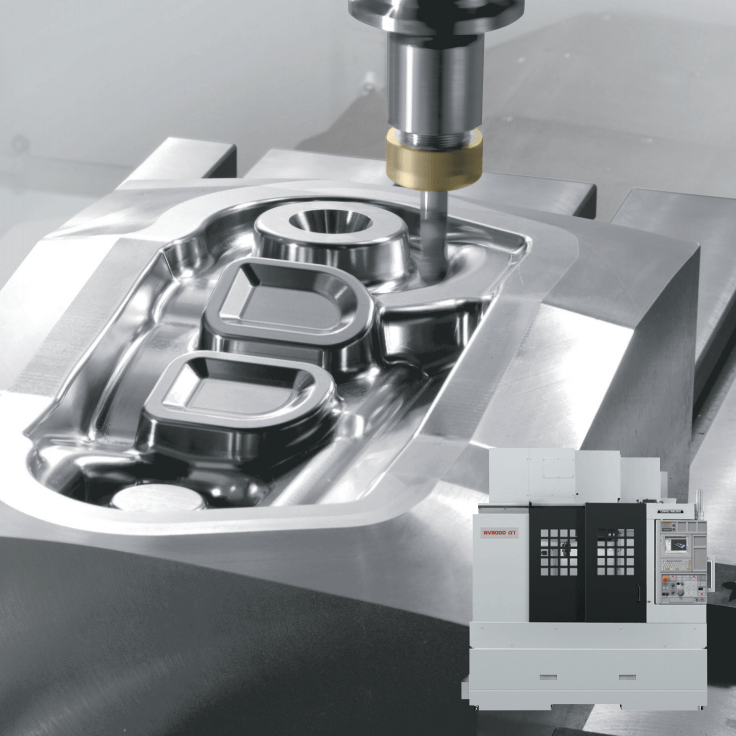

OUR PRECISION LASER CUTTING SERVICES

HYGRADE LASER PROFILING PROVIDES COMPLETE MANUFACTURING SOLUTIONS FROM START TO FINISH.

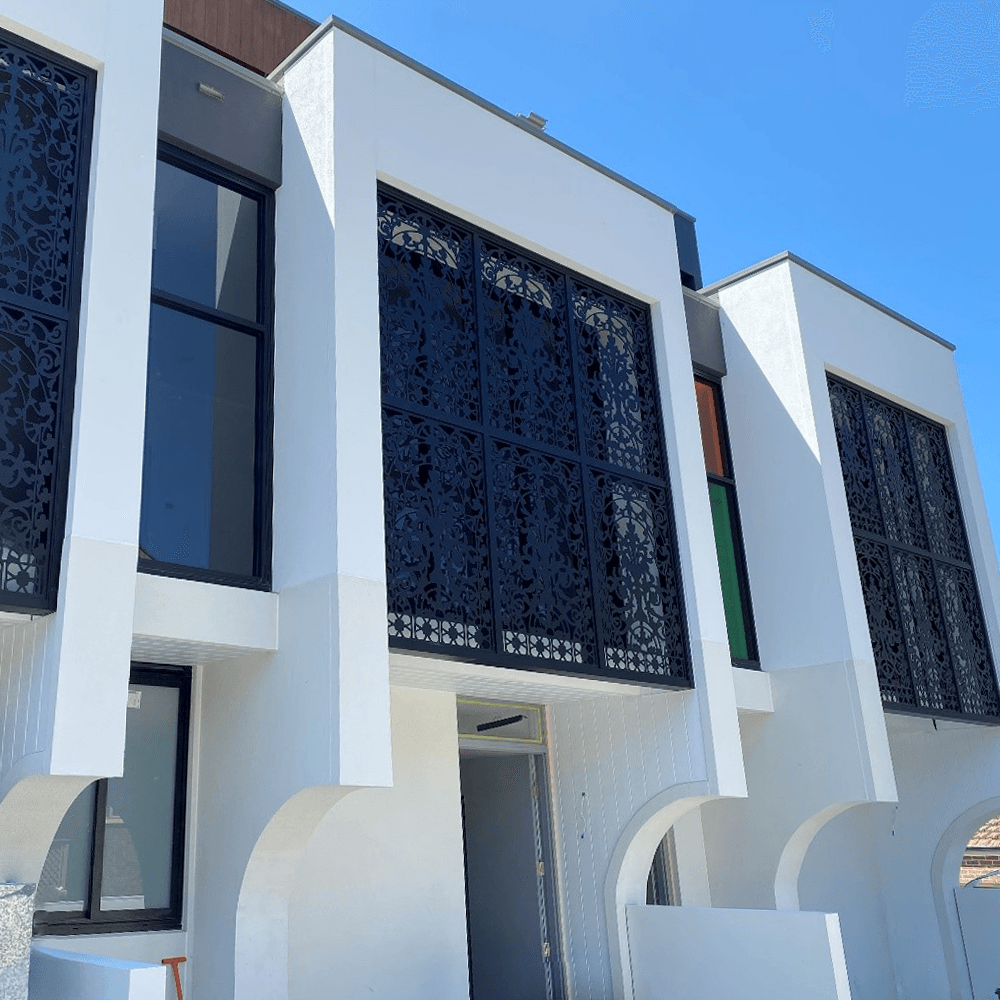

Our manufacturing techniques are now being used to create everything from tolerance critical components to elegantly crafted ornamental designs, in a stunning range of materials.

We customise and produce products for a range of industries from street furniture, food, mining, boating and motorsport industries, architectural pieces, even signage.

Hygrade Laser Profiling offers advanced equipment and technical expertise to turn your fabrication process into a competitive advantage.

Customers are assured of quality throughout the entire process to finished parts.

We don't cut plastic or timber.

EVERYTHING TO GET YOUR JOB DONE

ALL UNDER ONE ROOF

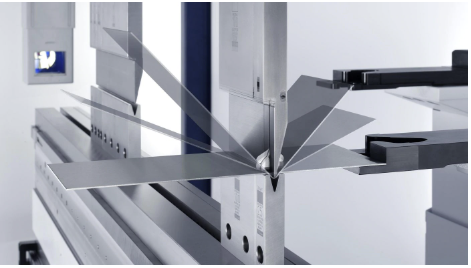

Laser Cutting

| x1 3030 8kW Fiber | x1 5030 5kW Fiber | x1 5030 8kW Fiber | x1 3000 Tube 2kW Fiber | |

|---|---|---|---|---|

| Mild Steel | 25mm | 25mm | 25mm | 6mm |

| Stainless Steel | 30mm | 25mm | 30mm | 6mm |

| Aluminum | 25mm | 25mm | 25mm | 5mm |

| Brass | 10mm | 10mm | 10mm | 4mm |

| Copper | 10mm | 10mm | 10mm | 4mm |

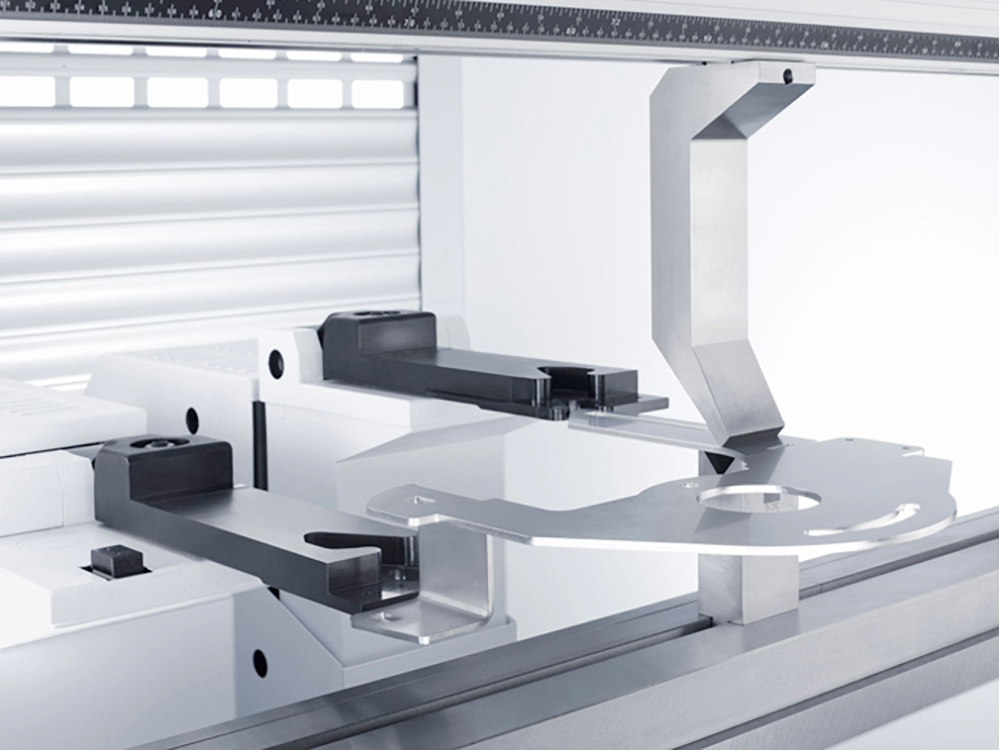

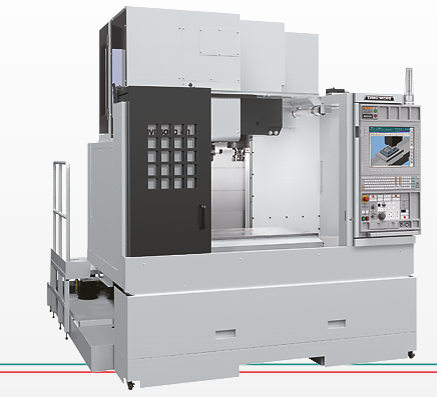

Bending/Folding

HYGRADE HAS ONE OF THE LARGEST TOOLING RANGES ALLOWING HYGRADE TO FOLD YOUR NEXT PROJECT.

Bending Service

| TWO MACHINES | AMADA HS 1703 | TRUMPF TRUBEND 5085 |

|---|---|---|

| MAX TONAGE | 170T | 110T |

| BENDING LENGTH | 3000MM | 2700MM |

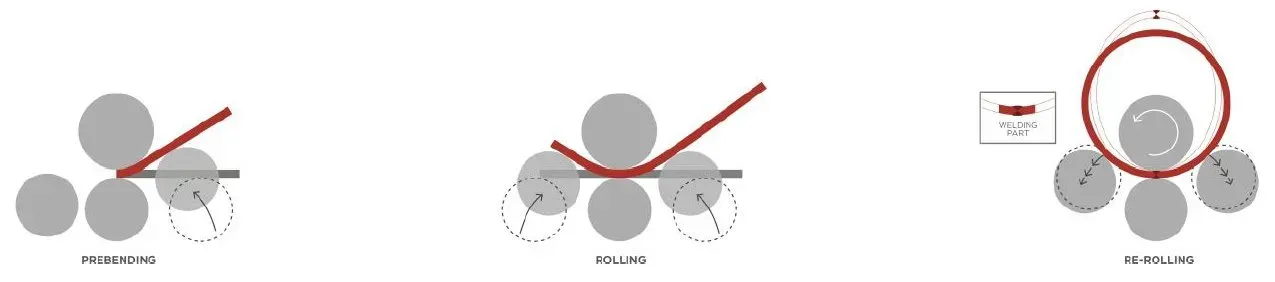

Rolling

PERFORMANCES

| Width | Thickness | Internal Diameter | Yield | UTS | |

|---|---|---|---|---|---|

| Rolling | 3000 mm | 14 mm | 1400 mm | 260 Mpa | 400 Mpa |

| Prebending | 3000 mm | 10 mm | 1400 mm | 260 Mpa | 400 Mpa |

TECHNICAL SPECIFICATIONS

| 100% manufactured in Italy by | DAVI |

| Model | MCA 3028 |

| Number of rolls | 4 |

| Rolls length | 3100 mm |

| Top roll diameter | 280 mm - less deflecting thanks to Planetary Guide Technology |

| Bottom roll diameter | 260 mm |

| Side rolls diameter | 200 mm |

| Smallest possible diameter | 310 mm - thanks to Planetary Guide technology |

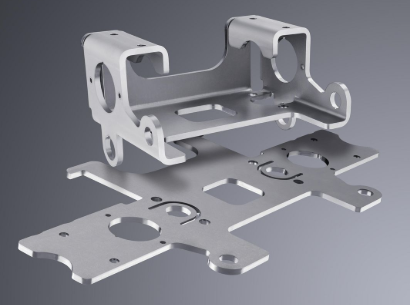

Fixings And Fastners

Self clinching fasteners

Nuts and studs from M2 to M12 can be pressed into the material under pressure, giving a secure fixing point for easy assembly.

Rivet nuts and pop riveting

Special tools enable us to assemble parts for our customers when required. Aluminium, steel and stainless steel can be riveted together.

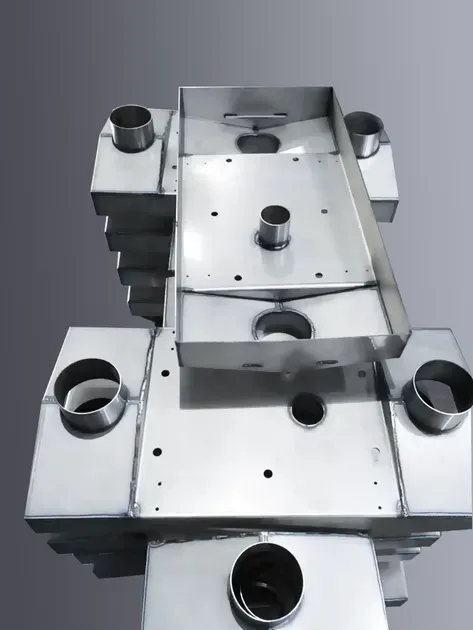

Welding

WE OFFER YEARS OF HANDS-ON INDUSTRY EXPERIENCE

As one of the first laser cutting job-shops in NSW, Hygrade’s history comes equipped with years of hands-on industry experience, technical knowledge, and superior customer service.

OUR COMMITMENT

Hygrade assures customers detailed laser cutting services, exceptional metal bending, and the best value for quality parts and on-time deliveries. We aim to meet and exceed our customers’ requirements.

Always preparing for the future, Hygrade uses comprehensive production planning systems that are designed for manufacturing sheet metal components. These systems allow parts to be made the most efficient way, keeping costs under control.