32 Harley Crescent Condell Park NSW, 2200 Australia

How Does Laser Cutting Work?

Laser cutting has significantly impacted various industries for years with its remarkable precision and versatility. But have you ever thought about how it actually works? In this blog, we'll delve into the process of laser cutting, covering everything from the components of a laser cutter to the available software options and essential safety measures to consider during the process.

By understanding the process behind laser cutting, we can learn more of the incredible potential it offers for both industrial applications and creative projects. If you want to find out how does laser cutting work, continue reading this blog.

How do lasers cut materials?

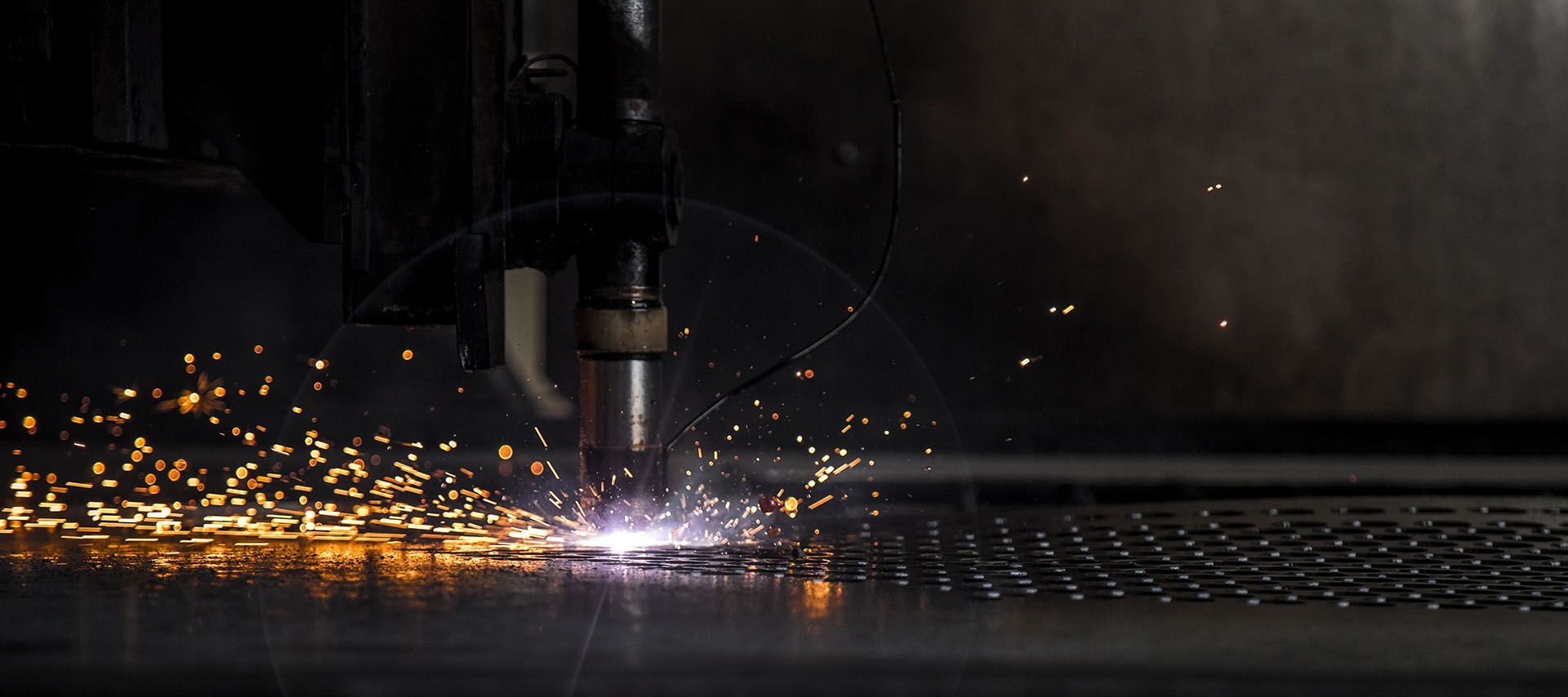

Laser cutters cut materials by emitting a focused laser beam of intense light energy onto the surface of the material. This energy heats up and vaporises or melts the material, allowing for precise cuts along a predetermined path. As this process takes place, control systems guide the laser beam's movement while assist gases can be used to blow away debris and and produce clean edges.

Components of a Laser Cutter

The components of a laser cutter typically include:

Laser Source

The laser source is the core component of a fiber laser cutting machine, serving as the “power source” that enables the cutting operation. It works by using specialised gas, liquid, or solid materials to create that beam. Compared to other types of lasers, fiber lasers offer higher efficiency, longer service life, reduced maintenance, and lower costs.

Laser Optics

Laser optics are a set of optical components in laser systems that shape, direct, and focus the laser beam onto the target material. They determine the quality and precision of the laser beam, which influences the outcome of various laser processing applications.

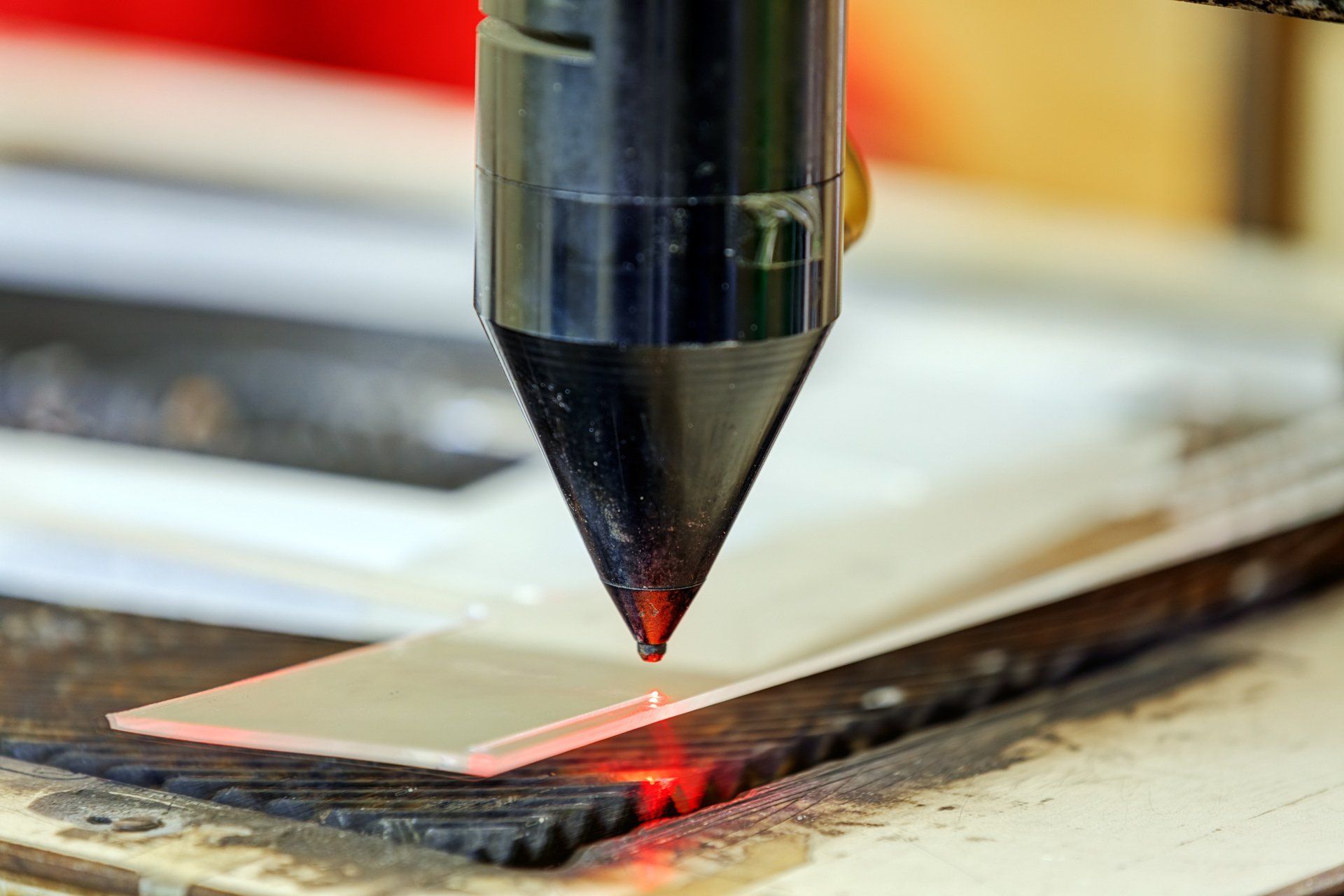

Laser Cutting Head

A laser cutting head is a critical component of a laser cutting machine responsible for delivering the laser beam to the material being cut. It consists of several key parts, including the nozzle, focus lens, and focus tracking system. It moves along the predetermined cutting path, but its height must be adjusted and controlled according to different materials, thicknesses, and cutting parameters.

Control System

The control system is a crucial element of a laser cutter, responsible for managing and regulating its various functions to guarantee precise and efficient cutting operations. It consists of hardware and software components that work together to control the laser source, beam delivery system, and cutting head.

Assist Gas System

Some laser cutters use assist gases, such as oxygen, nitrogen, and compressed air to improve the cutting process by blowing away debris and assisting in material removal. The assist gas system typically includes features for precise control of gas flow rate and pressure to promote optimal cutting performance for different materials and thicknesses.

The Laser Cutting Process

Here's a breakdown of how the laser cutting process works:

Design Preparation

When creating a design, you can use a computer-aided design (CAD) software to assist you in defining the shape and dimensions of the cut. Once the design or pattern is created, it serves as the blueprint for the laser fabrication process, providing precise instructions on how the cut should appear, including its size, shape, and other necessary details.

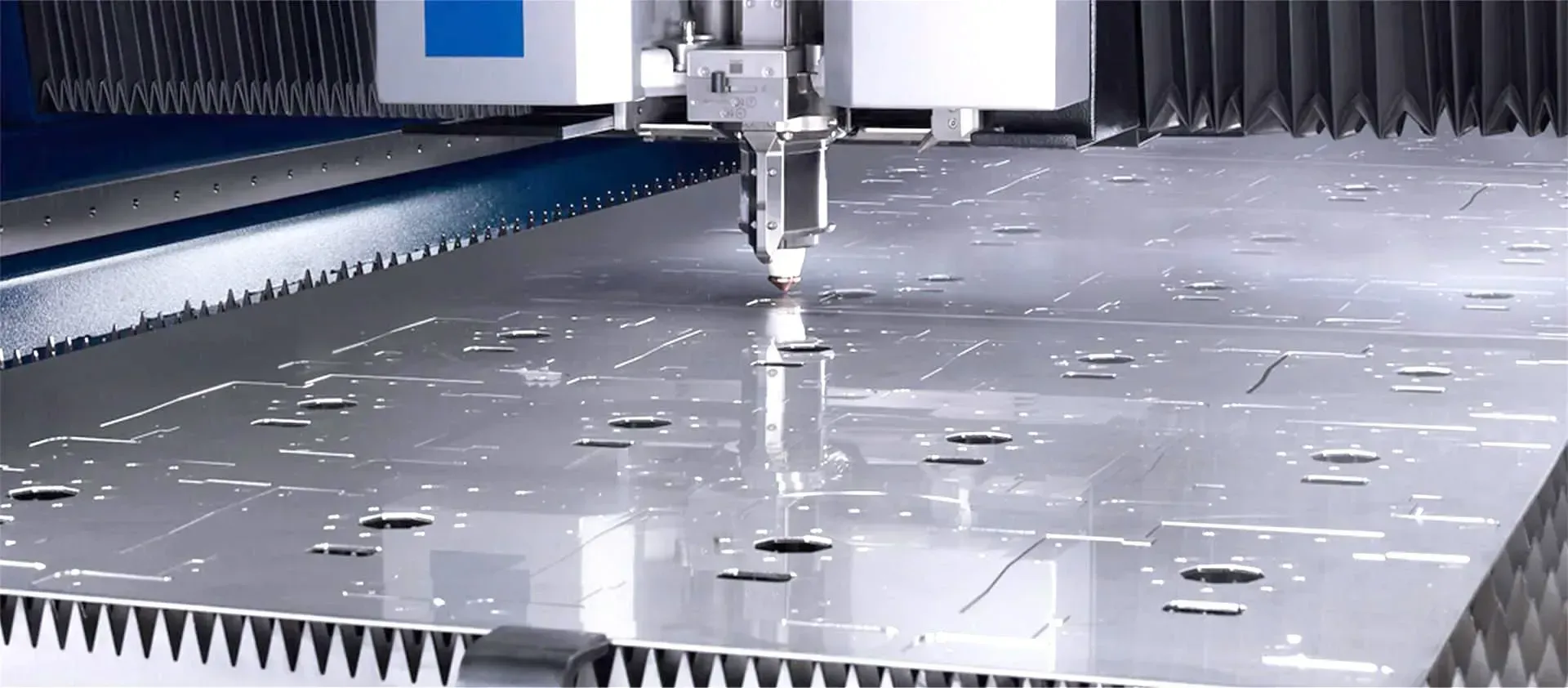

Material Setup

Place the material on the laser cutter's bed using clamps or a vacuum table to hold the material firmly and to cut it accurately based on the design file. Make sure the material's surface is clean and free of any contaminants to avoid interference with laser cutting.

Laser Beam Emission

Setup and configure the laser cutting machine with appropriate settings for power, speed, and focus based on the material type and thickness. During this process, the laser beam is then directed to the material surface through laser optics such as mirrors and lenses.

Material Cutting

When the laser beam makes contact with the material, it heats it up, causing it to either melt, vaporise, or burn away along the defined cutting path. During this process, the laser cutter's control system precisely moves the beam according to the design file.

Cooling and Finishing

Assist gases like nitrogen, oxygen, or compressed air may be used to blow away the molten material from the cutting area and prevent re-solidification. Once the cutting process is complete, the material is then removed from the cutting bed, and any finishing touches or post-processing steps may be applied as needed.

Software Options for Laser Cutting

Here are some of the most commonly preferred software options for designing and preparing files for laser cutting. Some popular choices used by a trusted laser cutting provider include:

CAD Software

Computer-aided design (CAD) and computer-aided manufacturing (CAM) software are widely used for designing and preparing files for laser cutting. CAD/CAM software helps create paths for tools and improves cutting settings, making the manufacturing process smoother and more efficient. These types of software enable designers and manufacturers to visualise, simulate, and optimise the entire production process, from initial concept to final output.

AutoCAD

AutoCAD is a widely used computer-aided design (CAD) software that allows users to create detailed 2D and 3D designs with precision and efficiency. Once created, these designs can be seamlessly exported in various file formats suitable for laser cutting, such as DXF (Drawing Exchange Format) or DWG (AutoCAD Drawing Database).

Adobe Illustrator

Recognised as the benchmark for vector graphics, Adobe Illustrator has earned its reputation as the go-to software for professionals and enthusiasts alike. Its intuitive interface and extensive toolset not only streamline the design process but also offer unparalleled versatility in creating intricate designs. Compatible with various file formats like SVG, PDF, and EPS, it shows powerful features such as shape manipulation tools, colour swatches, and styles that are ideal for design creation.

Inkscape

Inkscape is a free and open-source vector graphics editor that offers a wide range of tools and features that rival those of paid software. It supports a variety of file formats, including SVG (Scalable Vector Graphics), which is commonly used in laser cutting workflows. Its seamless SVG integration is compatible with laser cutting machines allowing for smooth transitions between design and production stages.

Understanding Safety Considerations of laser cutting

Laser cutting involves high-energy beams that can pose risks, making it crucial for you to adhere to necessary precautions and use appropriate safety equipment. Such safety considerations may include:

Safety Glasses

Laser safety glasses are essential to protect the eyes from direct or scattered laser light. They are specifically designed to filter out harmful wavelengths and prevent eye injuries that can be severe and permanent.

Protective Clothing

During laser processing, wearing protective clothing is essential to protect your skin from burns. Since you're working with high-intensity laser beams, you want to make sure that all exposed skin is covered with long sleeves and pants made from non-flammable materials.

Ventilation System

Laser cutting produces fumes and particles that can be hazardous to health if inhaled. Proper ventilation and exhaust systems are essential to remove these contaminants from the workspace, ensuring a safe environment for operators and minimizing potential health risks.

Fire Safety

Laser cutters can ignite fires if not properly managed or if cutting parameters are incorrect. To prevent such occurrences, implement strict safety protocols and closely supervise laser cutting operations to prevent fire hazards.

Operator Training

Laser cutting machines can be dangerous without adequate training. This emphasises the critical importance of operators undergoing comprehensive training programs to make sure they have the necessary skills and knowledge to operate the equipment safely.

Material Compatibility

Use materials approved for laser cutting and avoid materials that may produce toxic fumes or harmful reactions when cut with a laser.

Takeaway

Laser cutting is a precise and adaptable process that harnesses the power of focused light to achieve remarkable accuracy and versatility across various materials. Using different software options and advanced technology, it enables intricate designs to be executed with utmost precision. However, if you want to fully take advantage of its potential, safety must always be prioritised.

At Hygrade Laser Profiling, every aspect of our operations adheres to strict safety standards and best practices. Our laser cutting specialists only use state-of-the-art equipment from laser cutters to computer numerically controlled hydraulic press brakes to guarantee the best results. Contact us today to learn more about our services.

32 Harley Crescent Condell Park NSW, 2200 Australia

mail@hygradelaser.com.au

(02) 9791 1141

Find Us On: