32 Harley Crescent Condell Park NSW, 2200 Australia

Why Pipe and Tube Laser Cutting is Integral to the Mining Industry

Mining is one of the toughest industries, demanding equipment that can handle extreme conditions without failing. Every structure, machine, and support system must endure relentless pressure, abrasive materials, and harsh environmental factors. Whether it’s drilling into solid rock, transporting massive loads, or reinforcing underground tunnels, mining equipment takes a beating every day.

When a tool or component wears out, finding a fast and reliable replacement is critical to avoiding costly downtime. Mining operations can't afford long delays while waiting for essential parts. Pipe and tube laser cutting provides a faster, more efficient way to produce high-strength, wear-resistant replacements that match the durability of the original components.

Beyond replacements, some mining operations require custom-fabricated parts for specific tasks or modifications. Tube laser cutting enables the production of precisely cut, application-specific components that integrate seamlessly into existing machinery and infrastructure.

At Hygrade Laser Profiling, we work with mining companies, equipment manufacturers, and industrial suppliers to produce laser-cut pipes, tubes, and structural components designed for strength, reliability, and longevity.

In this blog, we explore how pipe and tube laser cutting supports the mining industry, enhances equipment performance, and minimises downtime.

The Role of Pipe and Tube Laser Cutting in Mining

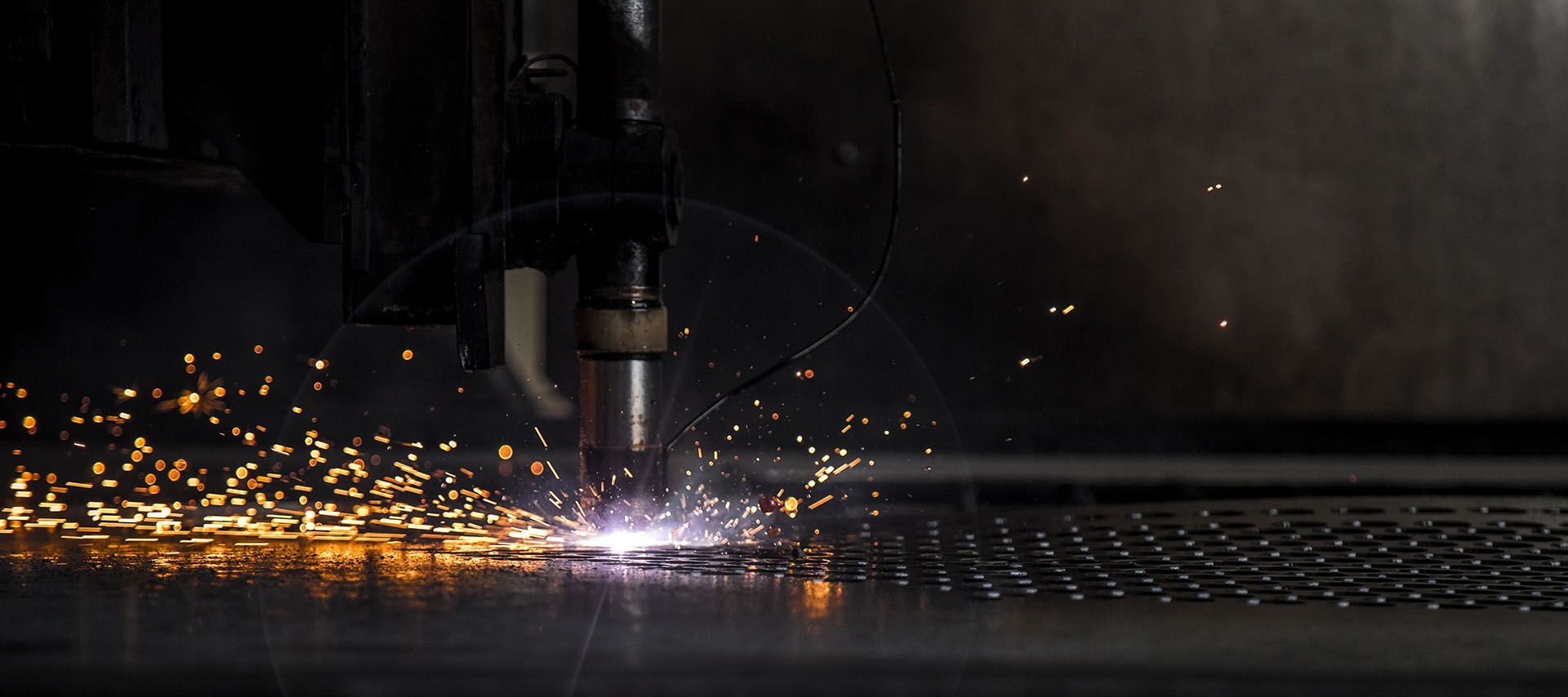

Mining machinery and equipment require high-strength, precisely fabricated components that fit properly and function reliably under extreme conditions. Pipe and tube laser cutting plays a critical part in fabricating structural, mechanical, and safety-related parts that keep mining operations running smoothly.

Wear-Resistant Components

Mining machinery undergoes constant impact, abrasion, and exposure to harsh elements. Laser-cut steel and alloy components help reinforce:

- Loaders, crushers, and excavators with custom-cut wear plates and structural supports

- Drill rig components that maintain strength and durability during deep-earth drilling

- Conveyor systems that transport extracted materials with minimal wear and tear

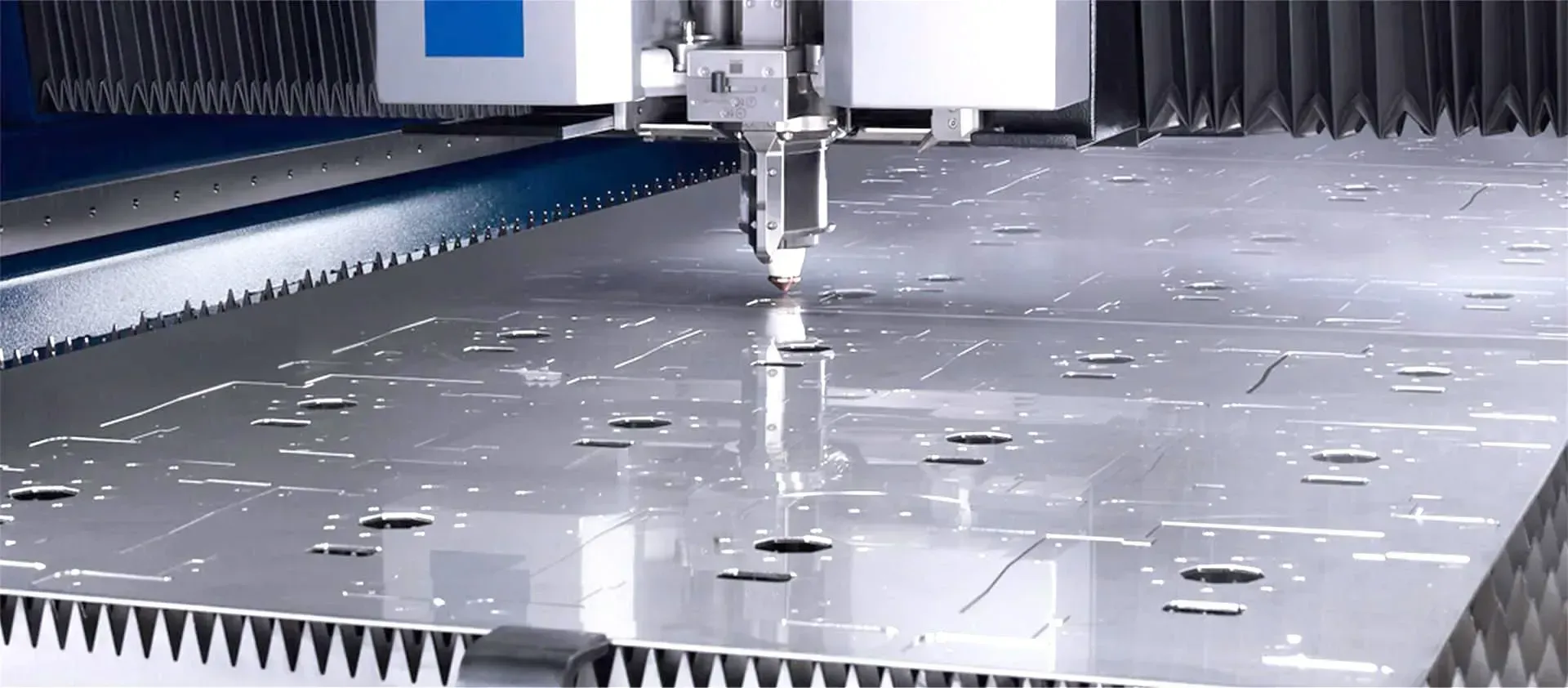

Pipe and Tube Sections for Mining Equipment

Mining operations require high-strength tubing and piping for drilling, processing, and fluid transport. Laser cutting provides:

- Cut-to-size pipe sections for drilling systems and borehole casings

- Custom tube components for ventilation, slurry transport, and hydraulic applications

- Reinforced pipe fittings and joints that ensure structural integrity under heavy loads

Brackets, Supports, and Reinforcement Parts

Mining equipment must be rigid and structurally stable to handle extreme conditions. Laser-cut brackets and supports help:

- Mount and secure machinery without weak points that compromise safety

- Provide reinforced supports for processing plants, screening stations, and crushing equipment

- Create custom frameworks that improve load distribution and equipment lifespan

Ventilation and Safety Structures

Underground and open-pit mining sites require proper ventilation and safety enclosures to protect workers and equipment. Pipe and tube laser cutting enables:

- Precision-cut ventilation ducts for controlled airflow in underground tunnels

- Protective enclosures and guards to shield machinery and workers from hazards

- Safety barriers and railings designed for durability and compliance with industry standards

Why Laser Cutting is the Best Choice for Mining Applications

Mining components must meet strict durability, precision, and performance standards because they operate under intense mechanical stress, extreme environmental conditions, and heavy loads on a daily basis. Pipe and tube laser cutting provides a faster, more accurate, and highly durable solution for fabricating these critical parts. Compared to traditional methods, laser cutting ensures:

High-Strength, Precision-Cut Parts

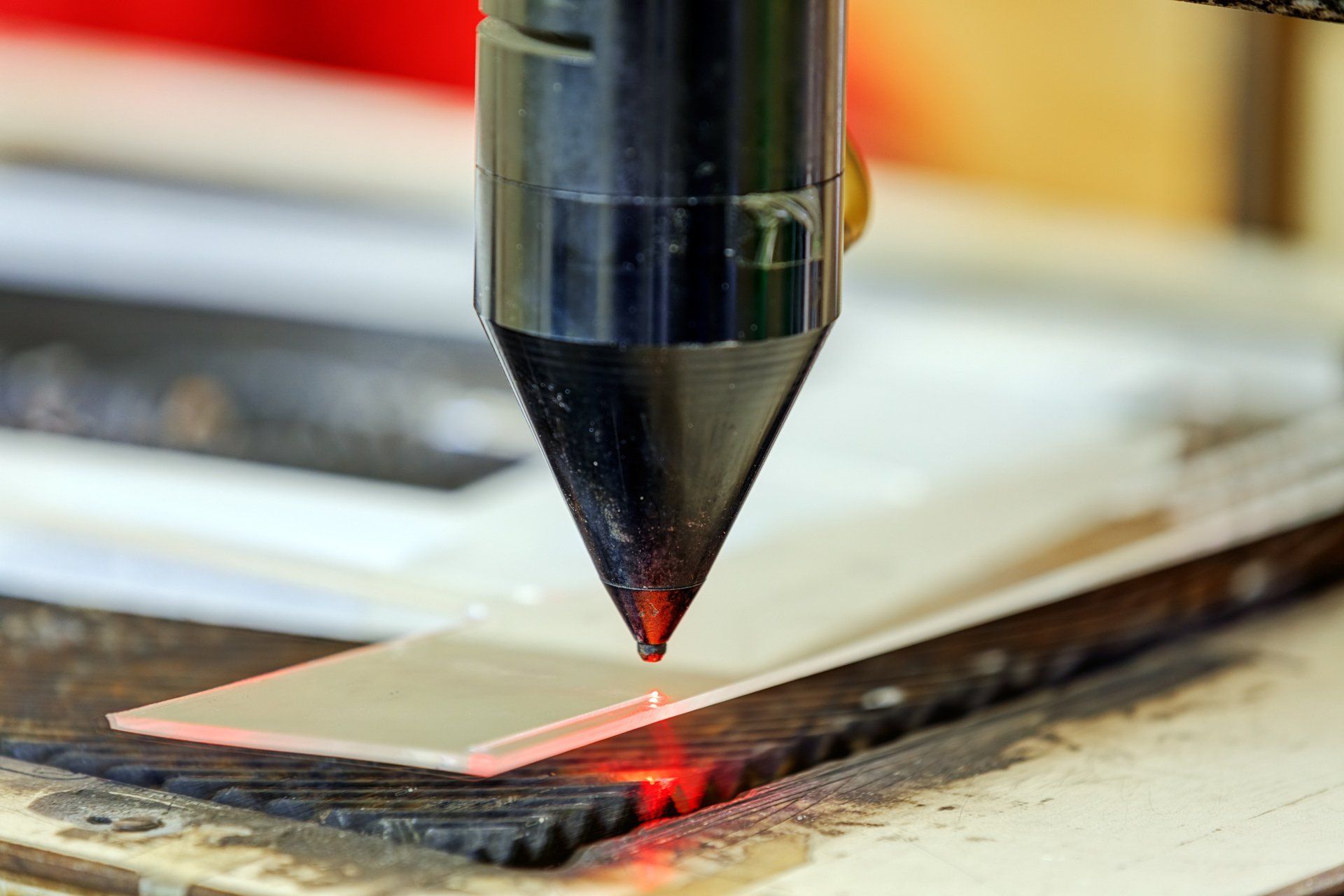

Mining equipment must be built to exact specifications to function correctly and endure extreme conditions. Laser cutting eliminates manual errors and material inconsistencies, so every piece is engineered for durability with accuracy.

Faster Production and Reduced Downtime

Equipment failures are unavoidable in mining, but long wait times for replacement parts don’t have to be. Laser cutting technology allows for rapid fabrication of high-strength replacements, minimising downtime and keeping operations moving.

Versatility for Different Metals and Thicknesses

Mining requires a variety of heavy-duty materials, including mild steel, stainless steel, and abrasion-resistant alloys. Pipe and tube laser cutting handles different material grades and thicknesses, making it suitable for everything from structural supports to protective casings.

Less Waste and Cost-Effective Fabrication

Maximising material use is essential in large-scale mining operations. Laser cutting minimises waste, scrap, and unnecessary material costs, improving overall project efficiency.

Stronger Welds and Seamless Assembly

Precision-cut edges allow for tighter fits and stronger welds, which is important for heavy-duty mining components that undergo extreme stress. Better fitment means fewer weak points and longer-lasting equipment.

Reliable Mining Components Built for the Toughest Conditions

Mining equipment operates in some of the harshest environments, where durability and reliability are non-negotiable. At Hygrade Laser Profiling, we manufacture laser-cut pipes, tubes, and structural components that meet the demands of heavy-duty mining applications.

Our expertise in high-precision fabrication ensures that every part — whether for replacement, reinforcement, or custom design — delivers exceptional strength, efficiency, and longevity. With fast turnaround times and advanced cutting technology, we help mining companies keep operations running at full capacity.

Need Custom-Cut Components for Your Mining Equipment?

Get in touch with us today to discuss your requirements.

Send us an enquiry, and let’s build something stronger together.

32 Harley Crescent Condell Park NSW, 2200 Australia

mail@hygradelaser.com.au

(02) 9791 1141

Find Us On: