32 Harley Crescent Condell Park NSW, 2200 Australia

Building Smarter: The Impact of Tube Laser Cutting on Construction Projects

The construction industry brings together countless components, from steel frameworks and load-bearing beams to intricate architectural details and safety structures. Every project, whether a high-rise, a bridge, or an industrial facility, relies on materials that must be strong, precise, and built to last.

Structural elements have a role that goes beyond basic support. They must withstand heavy loads, maintain stability under stress, and ensure the long-term safety of buildings and infrastructure. Every beam, column, and connection must be fabricated with care to prevent weaknesses that could lead to failures or costly repairs.

Manufacturers and builders need metal components that fit together properly to reduce the risk of weak joints, misalignments, or costly adjustments. When working with materials designed to withstand extreme loads and environmental stress, their accuracy is just as important as durability. Meeting these standards requires advanced fabrication techniques that eliminate inconsistencies and allow for efficient, large-scale production.

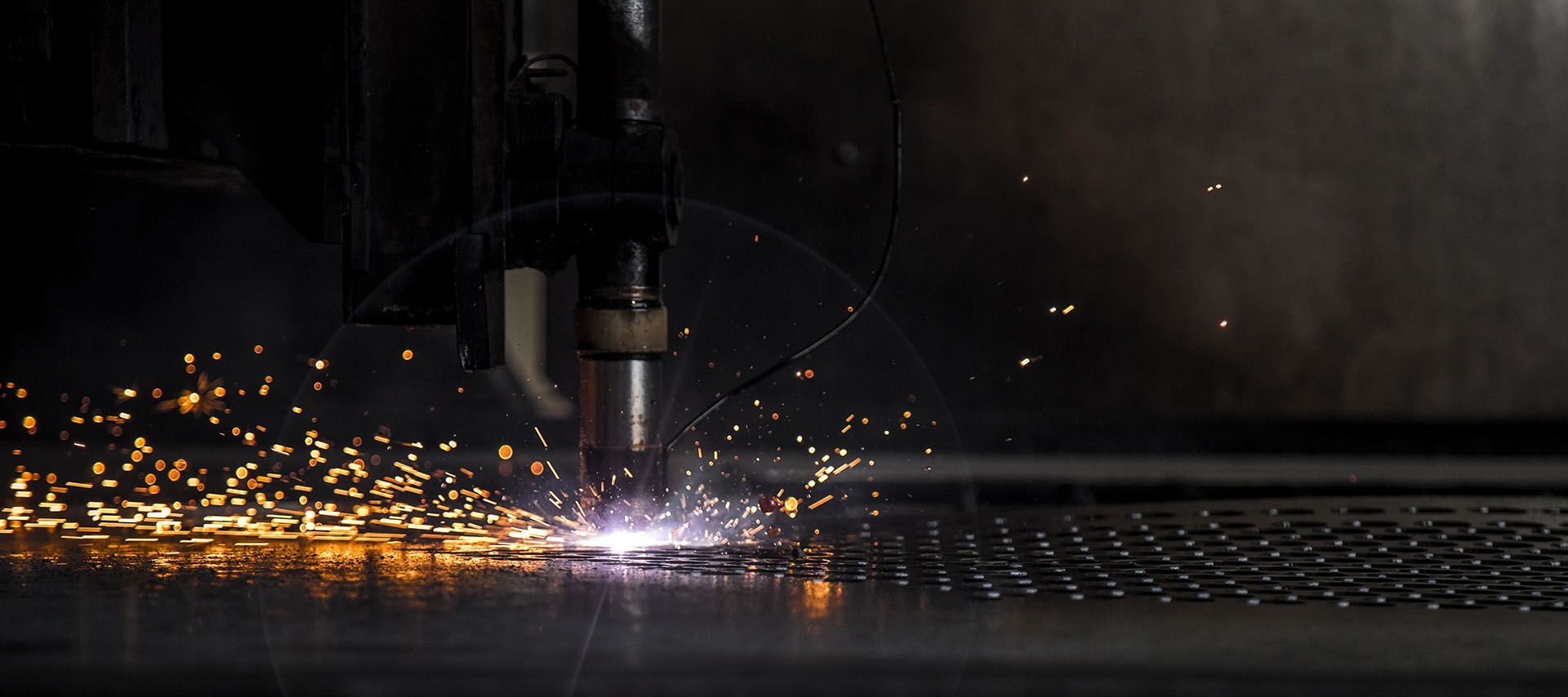

To meet these high standards, manufacturers and builders require cutting methods that offer both speed and precision without compromising material integrity. Tube laser cutting has become an essential part of modern construction due to its ability to reliably fabricate strong, accurately cut components that fit perfectly into any project.

The Role of Pipe & Tube Laser Cutting in Construction

Pipe and tube laser cutting has transformed the way construction materials are fabricated, which makes it easier to produce custom metal components that enhance strength, efficiency, and aesthetics. With the ability to cut complex shapes with pinpoint accuracy, it does indeed play a key role in modern construction and infrastructure projects.

Structural Steel & Framing

Precision-cut structural components ensure better alignment, stronger connections, and faster assembly. Pipe and tube laser cutting is used for:

- Steel beams, columns, brackets, and piping systems that form the framework of buildings and bridges.

- Support structures and reinforcements for large-scale infrastructure projects

- Custom-fabricated joints and connectors for modular construction

Architectural & Decorative Features

Beyond strength, modern construction projects demand aesthetic and functional metalwork. Laser-cut tubing is ideal for:

- Decorative screens and facade panels for architectural design

- Precision-cut stair components, handrails, and balustrades for residential and commercial buildings

- Custom metal signage and structural artwork

Construction Equipment & Machinery Parts

Heavy-duty construction equipment requires precise, durable metal components to function reliably. Pipe and tube laser cutting helps fabricate:

- Scaffolding and support frames for worksite safety

- Machine parts for cranes, lifts, and excavation equipment

- Pre-cut steel for temporary and permanent infrastructure

That being said, pipe and tube laser cutting has become an essential process in construction manufacturing for many reasons. Above all, it allows for precise, high-quality fabrication that ensures structural components fit correctly and perform reliably. Moreover, its efficiency reduces material waste and speeds up production, helping projects stay on schedule and within budget.

The Benefits of Pipe & Tube Laser Cutting in Construction

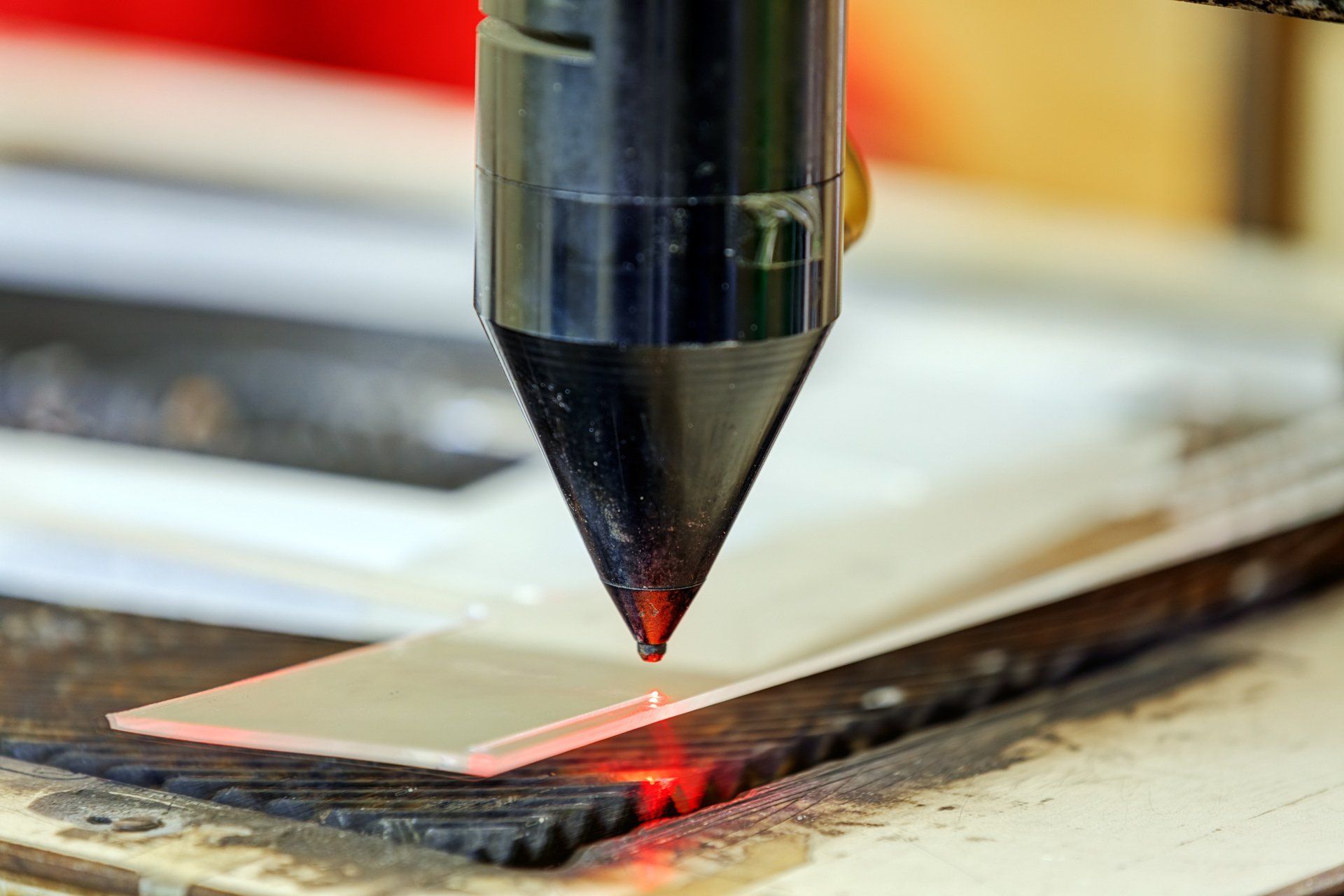

Higher Accuracy & Structural Integrity

Construction projects require precise, perfectly cut components that fit together without excessive modifications. Tube laser cutting eliminates human error and material inconsistencies. Rather, it produces structural components that are consistent in quality and ready for assembly.

Faster Fabrication & Project Timelines

Speed is an important factor in construction. Tube laser cutting streamlines fabrication by reducing cutting and shaping time. Pre-cut components arrive ready for welding and installation, which minimises or eliminates the need for adjustments and helps projects stay on schedule.

Versatility for Various Materials

Construction projects involve a wide range of metals, including mild steel, stainless steel, and aluminium. Tube laser cutting accommodates different materials and thicknesses, so it’s adaptable for everything from support structures to decorative features.

Reduced Waste & Cost Efficiency

Optimising material use is essential for controlling costs. Laser cutting technology minimises waste, allowing companies to get more from every sheet or tube of metal. Less scrap means lower material costs and a more sustainable construction process.

Stronger Welds & Seamless Connections

Clean, precision-cut edges improve welding quality, leading to stronger, longer-lasting joints. This is particularly important in load-bearing structures, where weld integrity affects building safety and durability.

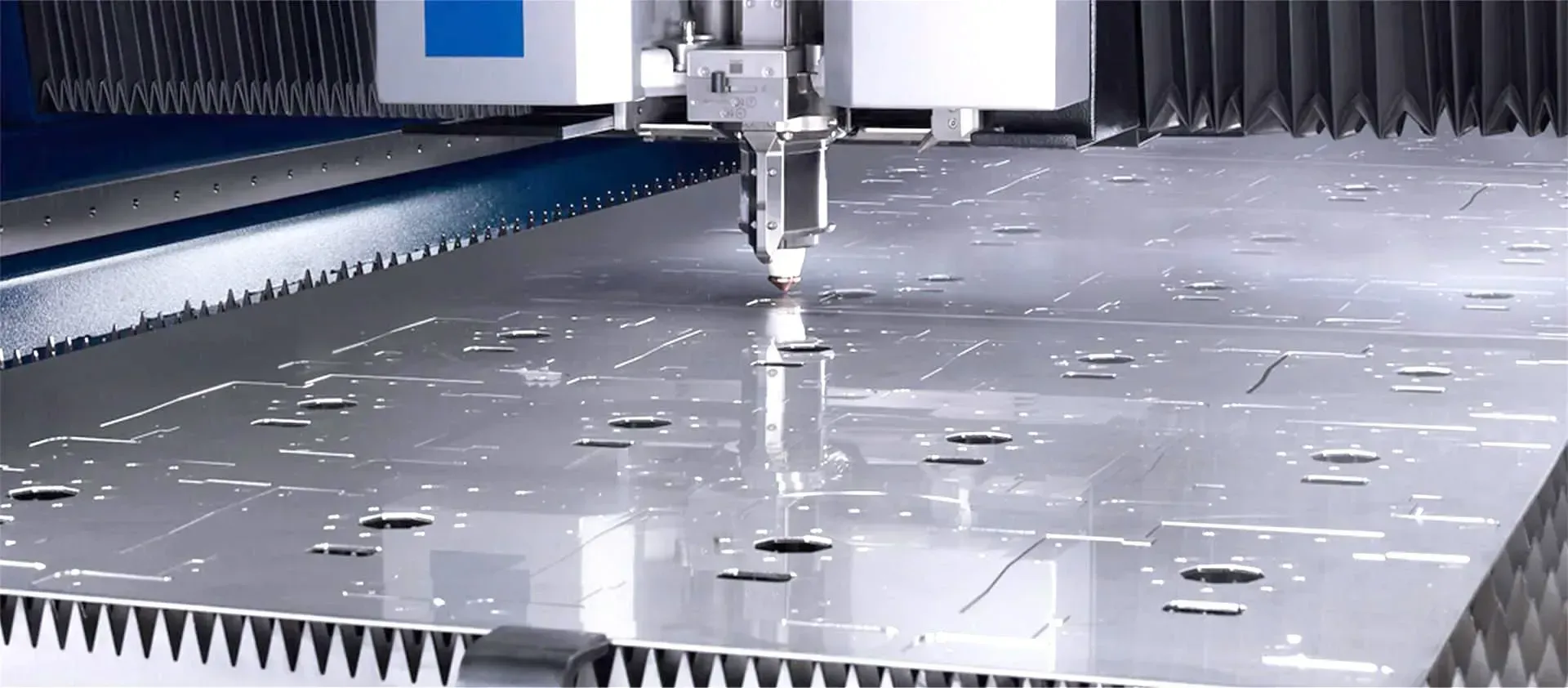

Building with Strength & Precision

At Hygrade Laser Profiling, we are a laser cutting provider in Sydney offering cut-to-size steel components, custom metalwork, and pre-cut pipes and tubing to support construction projects of all sizes. Our tube laser cutting technology ensures that every piece is precisely fabricated to exact specifications, down to the smallest detail, guaranteeing structural integrity and a perfect fit.

We help construction companies, steel fabricators, and infrastructure developers work faster, build stronger, and reduce costs.

Need Precision-Cut Components for Your Construction Project?

Get in touch with us today to discuss your requirements.

Send us an enquiry, and let’s build something stronger together.

32 Harley Crescent Condell Park NSW, 2200 Australia

mail@hygradelaser.com.au

(02) 9791 1141

Find Us On: