32 Harley Crescent Condell Park NSW, 2200 Australia

The Competitive Advantage of Tube Cutting for Agricultural Businesses

Agricultural equipment plays a very important role in sustaining communities. It ensures that farms operate efficiently to meet the growing demand for food. From tractors and irrigation systems to harvesting machinery and storage solutions, these machines are the backbone of food production. They don’t just assist in cultivation — they also help process and transport agricultural goods safely and efficiently to markets.

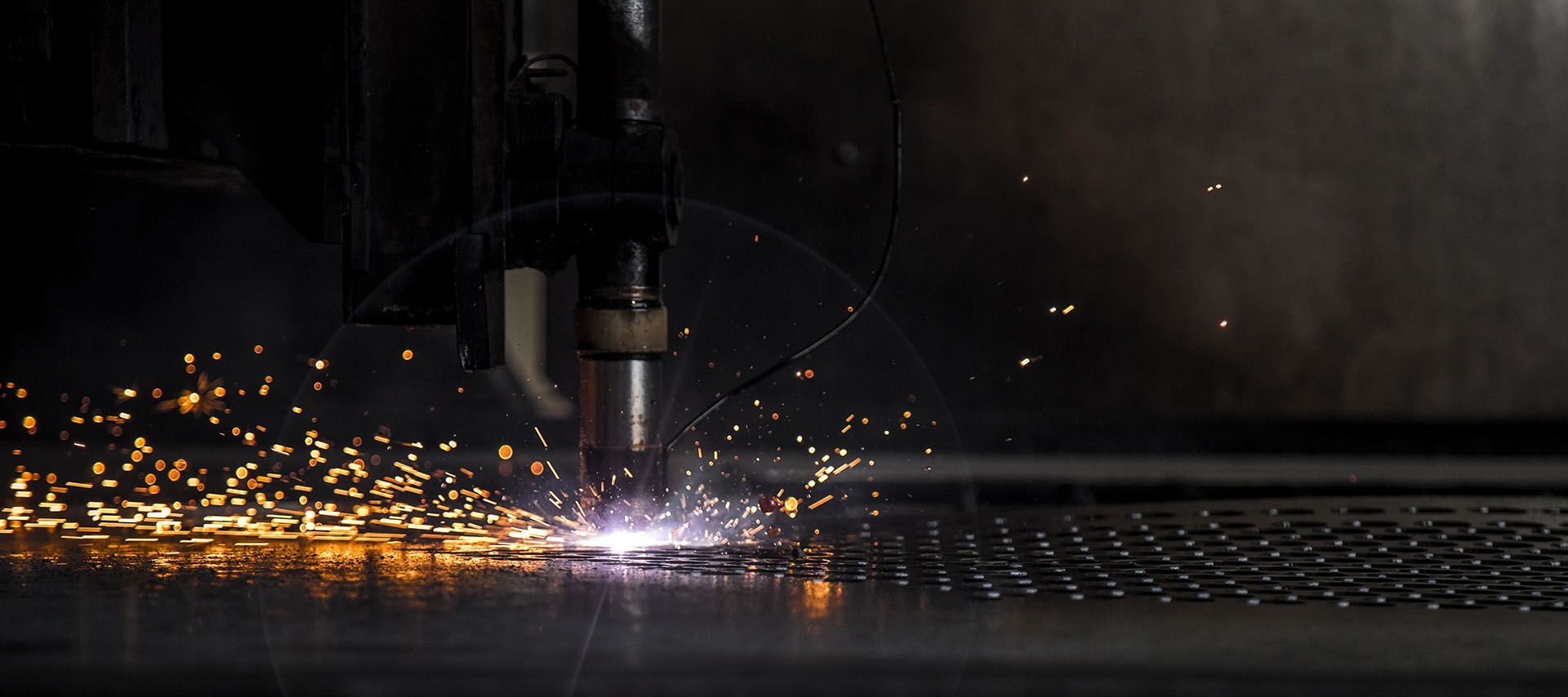

However, these machines operate under harsh conditions, enduring heavy loads, extreme weather, and continuous use. Over time, parts wear out, production timelines tighten, and manufacturers need reliable solutions to keep operations running. Many agricultural businesses and equipment suppliers lack the in-house capability, time, or resources to fabricate these complex components themselves. That’s where precision laser tube cutting makes all the difference.

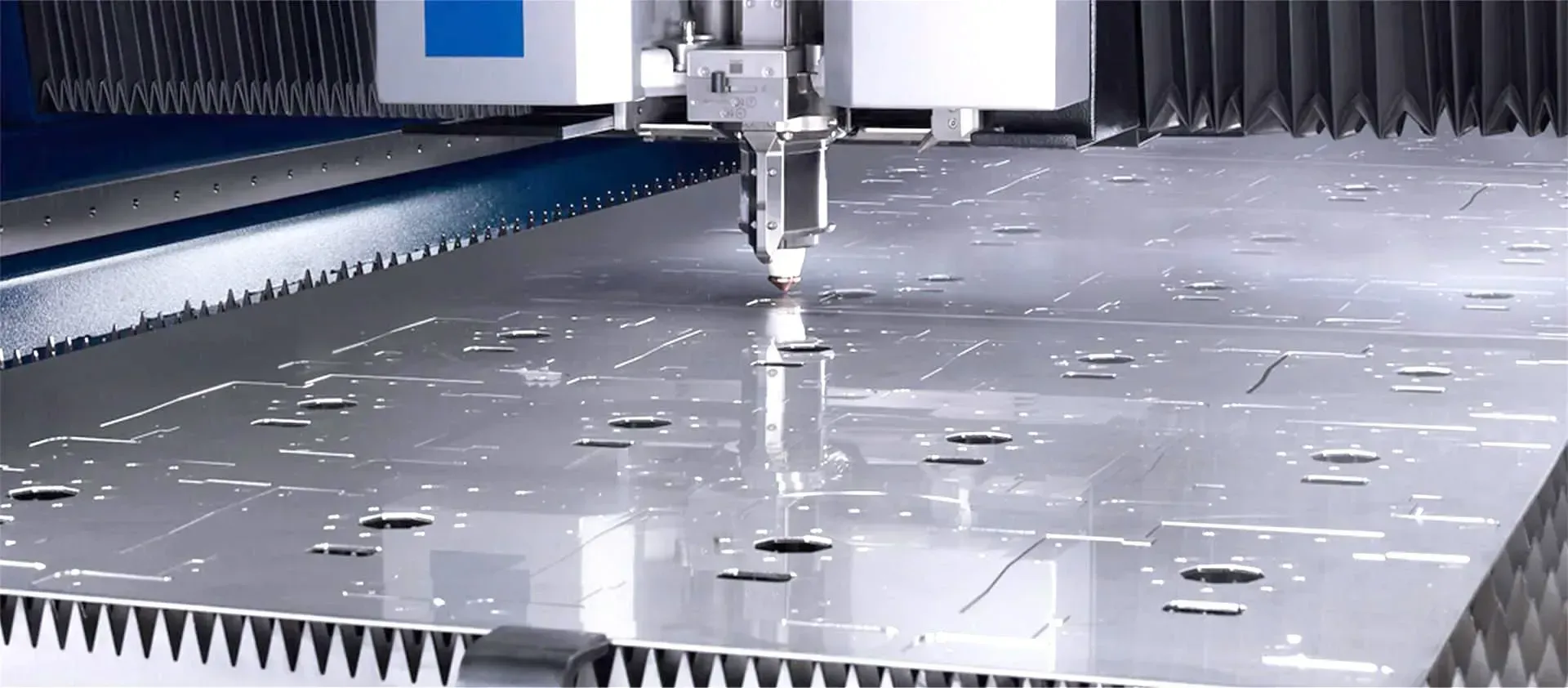

At Hygrade Laser Profiling, we provide custom-fabricated metal parts for everything from tractors and irrigation systems to combines and structural frames. Our Sydney laser cutting services help agricultural businesses streamline production, reduce waste, and ensure their machinery operates at peak efficiency.

The Role of Tube Cutting in Agricultural Equipment Design

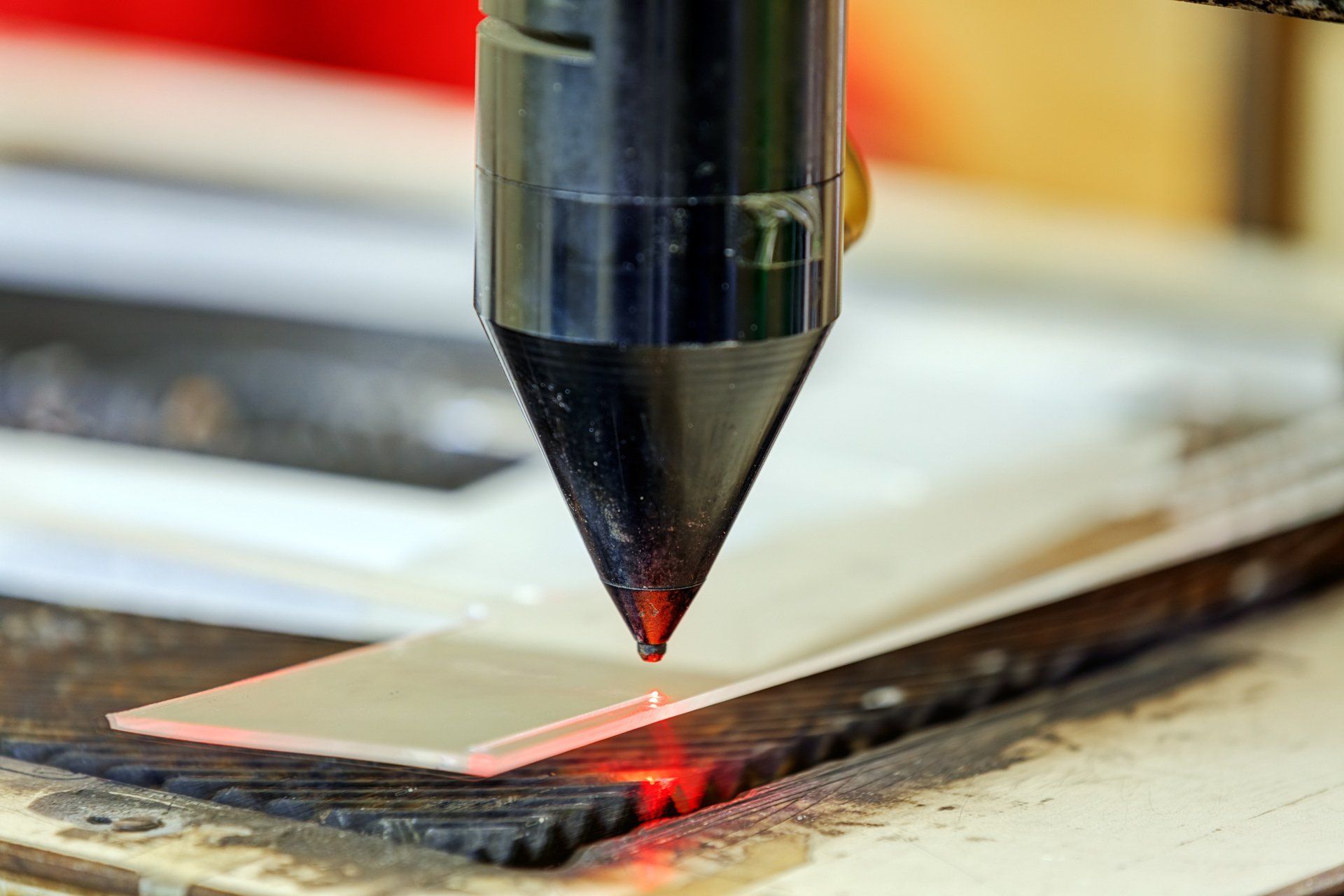

To keep up with increasing food demand, agricultural equipment must be built to work harder, last longer, and operate with greater efficiency. Off-the-shelf parts often fail to meet these exact needs, making custom-fabricated components essential for manufacturers designing modern machinery.

With Hygrade Laser’s expertise, we can create high-strength tubing, support structures, and mechanical components that keep agricultural operations running smoothly. Our flexible cutting capabilities allow us to design and manufacture parts for a wide range of applications:

- Tractors & Heavy Machinery: Custom-cut tubing for chassis, roll bars, and protective enclosures.

- Irrigation Systems: Precision-cut pipes, connectors, and support frames for efficient water distribution.

- Harvesting Equipment: Structural tubing and laser-cut parts for grain conveyors, threshers, and processing machinery.

- Storage & Transport: Durable steel components for silos, transport racks, trailers, and fencing systems.

Through the utilisation of advanced tube cutting techniques, we help agricultural businesses streamline production, reduce material waste, and enhance the durability of their equipment.

Tube Cutting for Agricultural Businesses & Farmers

Tube laser cutting isn’t just for manufacturers. Farmers and agribusinesses also rely on custom-fabricated components to keep their equipment running efficiently, especially when replacement parts are hard to find or costly.

Beyond large-scale manufacturers, farmers and agribusinesses also rely on precision tube cutting for their day-to-day operations. Agricultural equipment is usually used in harsh environments, leading to wear, damage, and breakdowns over time. When standard replacement parts are unavailable or modifications are needed, custom-fabricated components help prevent downtimes or keep them down to a minimum.

Our tube cutting services support agricultural businesses by providing:

- Custom Replacement Parts: Fabricated tubing to match damaged or outdated components that are no longer in production or are more expensive to procure from traditional sources.

- Machinery Modifications: Structural reinforcements, attachments, or design upgrades for tractors, trailers, irrigation systems, and harvesting equipment.

- Small-Scale Fabrication Needs: Custom-cut supports, brackets, and reinforcements for farm equipment repairs.

We work with farmers, equipment suppliers, and manufacturers to ensure the entire agricultural sector has access to precision-cut, high-performance components when they need them most.

The Advantage of Laser Tube Cutting

Laser tube cutting is the most efficient and precise method for manufacturing complex agricultural components. It works with a variety of materials, including steel, to provide unmatched accuracy, faster turnaround times, and stronger, more durable parts. This makes it ideal for agricultural equipment, which often requires unique structural designs and tight tolerances.

Agricultural equipment comes in all shapes and sizes, often requiring complex cuts, tight tolerances, and unique structural designs. Not all cutting methods can handle these challenges, but laser tube cutting provides a superior solution with benefits that include:

- Precision Engineering: Achieves highly accurate cuts for seamless assembly and stronger structural integrity.

- Faster Turnaround: Streamlined fabrication reduces lead times and downtime for manufacturers.

- Versatile Cutting Capabilities: Handles round, square, oval, D-shaped, and custom-profile tubing.

- Stronger, More Durable Parts: Minimises weak points, reducing wear and tear for longer-lasting equipment.

As agriculture evolves, so does the need for stronger, more efficient, and precisely manufactured equipment. Whether you're producing large-scale machinery or fine-tuning existing farm equipment, having the right metal components can make all the difference.

With Hygrade Laser Profiling, agricultural manufacturers and businesses get customised solutions that fit their exact equipment designs and operational needs.

Custom Metal Fabrication & Tube Cutting for a Smarter Farming Future

Reliable agricultural equipment is the backbone of food production, and strong, precision-cut components are what keep it running. At Hygrade Laser Profiling, we provide the high-quality metal fabrication needed to support this essential industry. Contact us today to discuss how we can help power the future of farming.

32 Harley Crescent Condell Park NSW, 2200 Australia

mail@hygradelaser.com.au

(02) 9791 1141

Find Us On: