32 Harley Crescent Condell Park NSW, 2200 Australia

Blog Layout

Industry 4.0: Getting Connected with TRUMPF

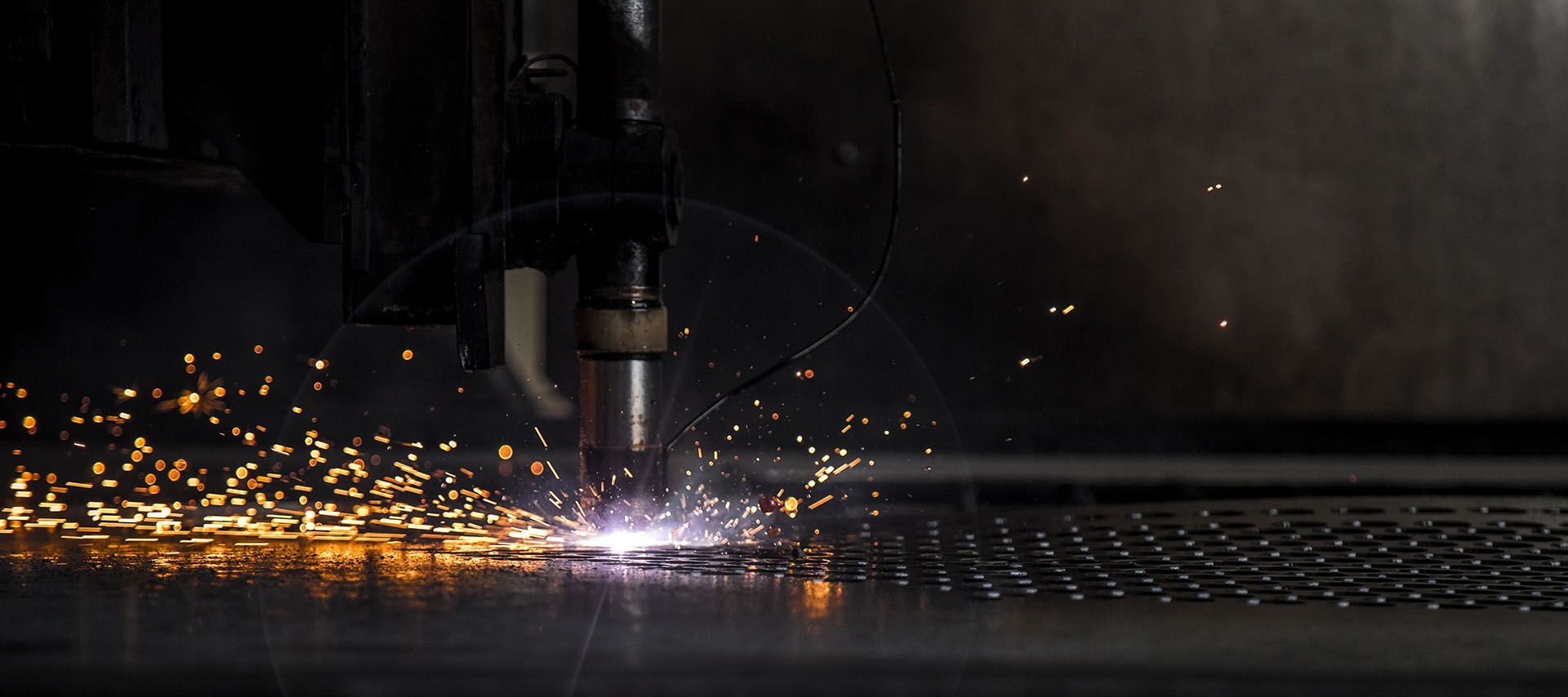

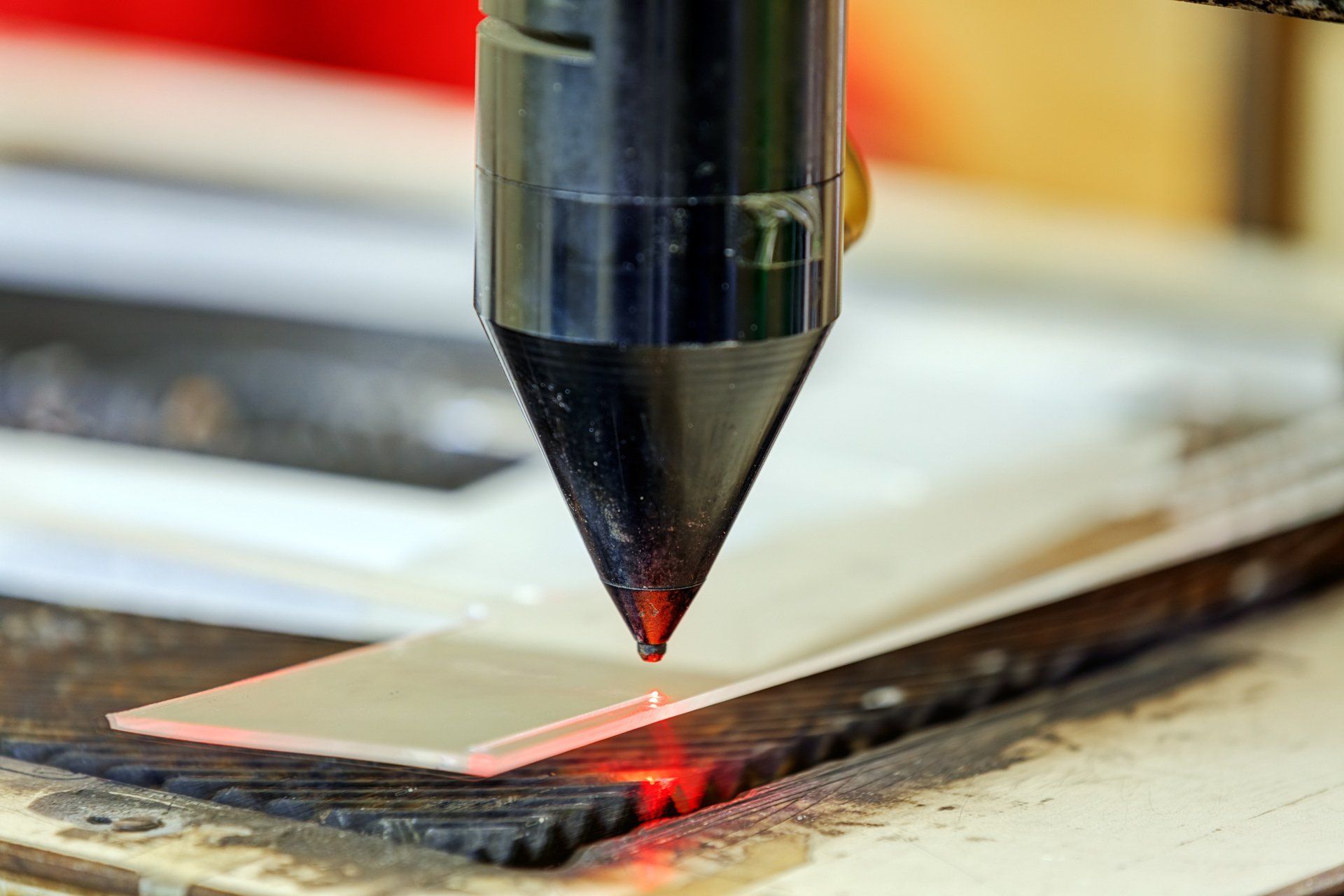

Industry 4.0 is the current trend of automation and data exchange in manufacturing technologies, and is being spoken about everywhere. This includes cyber-physical systems, the Internet of Things and cloud computing.

With what’s being referred to as the Fourth Industrial Revolution, manufacturing is set to become more flexible and productive than ever before.

Underneath the concept of 4.0 lies the Smart Factory, encompassing self-configuring production resources and the connected planning and control systems. It uses a network to link both virtual and physical production elements by introducing the “Internet of Things” to manufacturing operations.

TRUMPF, world renowned industry experts, are already ahead in aligning their business with Industry 4.0. Their production unit was moved to Ditzingen to work following digital process flows.

TRUMPF say their move has been positive, giving employees an improved overview of their work and they expect productivity to rise by 30% in the next few years.

Read more about TRUMPF getting connected here.

RECENT POSTS

Hygrade Laser Profiling has over 30 years professional experience in producing quality manufactured products through laser cutting, with great service that meets the needs of our local clients.

32 Harley Crescent Condell Park NSW, 2200 Australia

mail@hygradelaser.com.au

(02) 9791 1141

Find Us On: