32 Harley Crescent Condell Park NSW, 2200 Australia

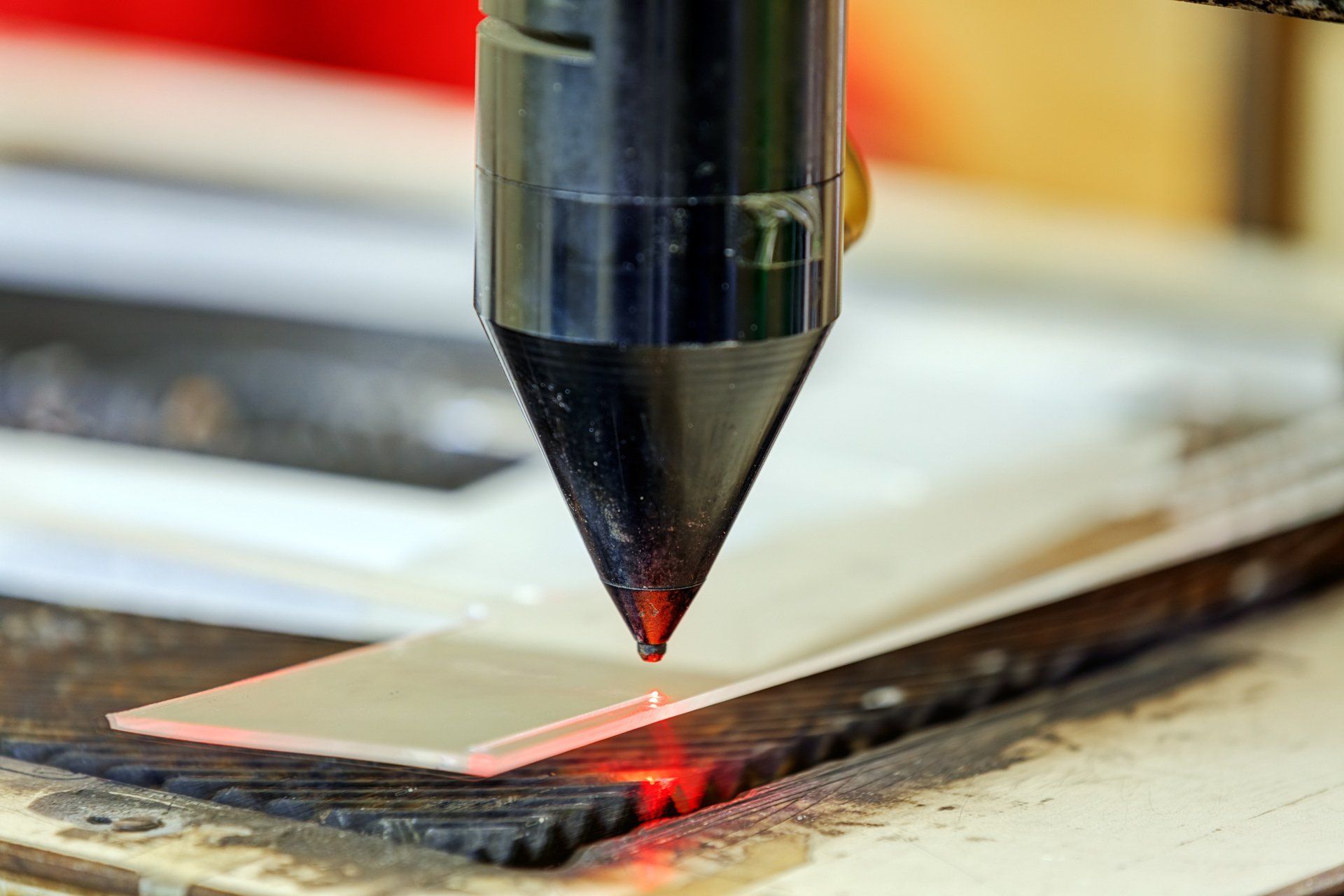

Unveiling the Latest Innovations and Trends in Laser Cutting Technology

Laser technology has evidently come a long way, evolving from its early stages to its current state-of-the-art applications. Despite significant progress, laser cutting innovation still has a long way to go. In this blog, we'll delve into the latest innovations, sustainable practices, emerging trends, and various applications of laser cutting. From automotive to electronics and construction, this blog will reveal how this cutting-edge technology is revolutionising different industries and driving the future of fabrication. Continue reading this blog to learn more.

Latest Technological Advancements of Laser Cutting

Laser cutting has undergone significant development over the years, revealing remarkable trends such as:

Increased Power and Speed

The laser industry is recognised for using higher power lasers that are driven by advancements in laser diode technology. This allows for faster cutting and the ability to cut through thicker materials.

Innovations in Material Compatibility

Innovations in laser cutting have significantly expanded the range of compatible materials, enabling the processing of materials that were previously difficult or even impossible to handle.

Improved Precision and Accuracy

Advancements in control systems, motion systems, and beam delivery have led to improvements in cutting precision and accuracy.

Integration with Automation

Laser cutting systems are increasingly being integrated with robotics and computer numerical control (CNC) systems for precise and automated fabrication processes.

Adaptive Optics

Some laser cutting systems now incorporate adaptive optics, which dynamically adjust the laser beam's focus to compensate for material inconsistencies, surface irregularities, and other factors. This helps maintain a consistent cutting quality across various materials and thicknesses.

Integration with CAD/CAM Software

Laser cutting machines are increasingly integrated with computer-aided design (CAD) and computer-aided manufacturing (CAM) software to streamline the workflow from design to production and enable greater design flexibility.

Sustainable Laser Cutting Practices

Sustainable laser cutting practices aim to minimise environmental impact and resource use while maintaining efficiency and effectiveness.

Use of Energy Efficient Components

Unlike other forms of machining processes, laser cutting machines can be optimised to consume less energy while maintaining their cutting quality. This can be achieved through the use of power supplies and cooling systems, as well as by implementing software and hardware optimisations to reduce energy waste during operation.

Material Optimisation

Sustainable laser cutting practices involve minimising material waste by optimising cutting patterns, putting parts closely together to reduce scrap, and using leftover materials whenever possible. This practice not only reduces material consumption but also lowers costs associated with purchasing and disposing of materials.

Recycling and Waste Reduction

Laser cutting produces waste materials, such as offcuts, dust, and fumes, which can all contribute to pollution. To minimise this, sustainable practices may involve implementing recycling programs for scrap materials and using filtration systems to properly dispose of dust and fumes.

Water and Resource Management

Some laser cutting processes require water as a medium for material processing. They use water to reduce the heat-affected zone, minimise material deformation, and prevent the buildup of fumes and debris. In some cases, water can also be used to cool the laser and its components during cutting.

Alternative Materials and Processes

A laser cutting specialist can enhance sustainability by exploring alternative materials like bamboo or recycled plastics and adopting eco-friendly technologies, such as laser cutting with compressed air instead of harmful gases.

Predictions and Emerging Trends of Laser Cutting

As the technology continues to advance, the possibilities for laser cutting are expected to grow.

Increased Precision and Speed

Laser cutting machines are expected to produce more intricate designs and complex cuts within shorter time frames. This trend is expected to continue driving manufacturers to produce high-quality products with greater efficiency to meet the demands of an increasingly competitive market.

Hybrid Laser Cutting

Hybrid laser cutting combines laser cutting with other techniques like milling or waterjet cutting, offering increased flexibility and efficiency in handling diverse materials and creating intricate shapes that may be difficult to achieve solely with laser cutting.

Expanded Material Compatibility

Laser cutting was traditionally limited to certain materials like metals and plastics. However, advancements in laser technology have expanded the range of materials that can be cut, including ceramics, glass, wood, and even fabrics.

Industry 4.0 and Digitalisation

The adoption of Industry 4.0 principles, such as the Internet of Things (IoT) connectivity and data analytics have revolutionised manufacturing processes by enabling predictive maintenance and optimising resource allocation for increased efficiency and productivity. Smart laser cutting machines equipped with sensors can gather real-time data on performance and productivity.

Integration with Artificial Intelligence (AI)

The integration of artificial intelligence (AI) and machine learning algorithms into laser cutting machines is set to transform the manufacturing industry. Laser cutting machines powered by AI will possess the ability to independently fine-tune cutting parameters, anticipate maintenance requirements, and swiftly adjust to evolving production demands.

Additive Manufacturing

Laser cutting and additive manufacturing, like 3D printing, can work together effectively for a fast and accurate creation of intricate structures and innovative product designs. This merging of methods is anticipated to become increasingly popular in industries like aerospace, automotive, and healthcare.

Environmental Sustainability

With the rising environmental issues, forthcoming advancements in laser cutting technology are now more focused on sustainability and eco-friendliness. There will be efforts to lower energy usage, diminish material waste, and refine recycling procedures.

Customisation and Personalisation

As consumer demand for customised products grows, so too will the adoption of laser cutting technology for mass customisation. From personalised consumer products to bespoke industrial components, laser cutting allows for cost-effective production of unique designs.

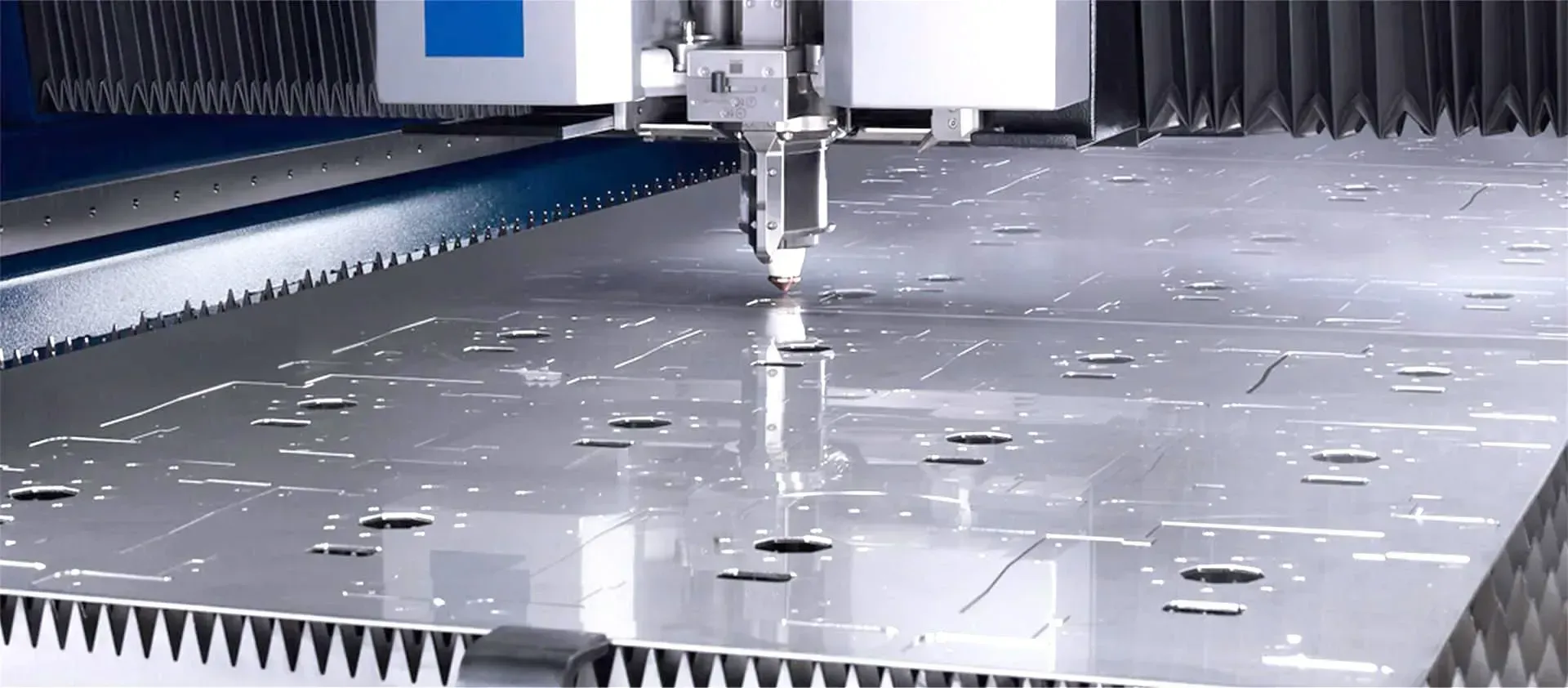

Innovative Laser Cutting Applications Across Industries

Laser cutting technology has revolutionised various industries with its precision, versatility, and efficiency. Here are some industries that have benefited abundantly from its advancements:

1. Automotive Industry

Laser cutting is widely used in automotive manufacturing for precise cutting of sheet metal components, such as chassis, body panels, and exhaust systems. Through this technology, it’s easy to produce intricate designs for customised parts.

2. Aerospace Industry

In aerospace, laser cutting is utilised for fabricating lightweight components with complex geometries, such as turbine blades and structural components. Moreover, it enables the use of advanced materials like titanium and composites.

3. Electronics Manufacturing

Laser cutting is essential for the production of printed circuit boards (PCBs) and microelectronics. It allows for precise cutting of delicate materials such as copper, fibreglass, and ceramic substrates without causing damage.

4. Medical Devices

Laser cutting is used in the manufacturing of medical devices, such as stents, catheters, and surgical instruments. With its capacity to create highly precise and sterile components, laser cutting enables the production of intricate parts with minimal heat-affected zones.

5. Construction Industry

Laser cutting is utilised to create precise components and structural elements in the construction industry, ranging from architectural pieces and facade panels to reinforcement brackets and intricate framework components.

6. Metalworking Industry

Laser cutting is used extensively in the metalworking industry for its ability to precisely shape various metals such as steel, aluminium, and titanium. This capability makes laser cutting an essential tool for industries requiring high accuracy, tight tolerances, and quick production turnaround times.

Takeaway

Laser cutting continues to revolutionise industries with its precision, efficiency, versatility and innovative capabilities. As technology advances, we can expect to see further innovations that will not only enhance the capabilities of laser cutting but also shape the future of manufacturing, design, and engineering.

At Hygrade Laser Profiling, we strive to stay at the forefront of these advancements by integrating the latest laser cutting technologies into our processes. Our team of experienced professionals combines technical expertise with state-of-the-art equipment to consistently deliver high-quality solutions tailored to our clients' unique needs. Get in touch with us today to find out more about our laser cutting services.

32 Harley Crescent Condell Park NSW, 2200 Australia

mail@hygradelaser.com.au

(02) 9791 1141

Find Us On: