32 Harley Crescent Condell Park NSW, 2200 Australia

The Science Behind Laser Technology: How Lasers Work

Do you ever wonder what makes lasers so powerful and precise? At their core, lasers are fascinating devices that harness the principles of physics and optics to produce focused beams of light. This technology has revolutionised numerous fields, from medicine and telecommunications to manufacturing and entertainment. Understanding how lasers work not only demystifies their capabilities but also highlights their importance in our everyday lives.

In this blog, we'll delve into the science behind laser technology, exploring the key components that make lasers function, the various types of lasers, and their multiple applications. Whether you're just curious about how lasers work or you're an expert in the field, this blog will provide you with a deeper appreciation for this incredible technology and its impact on our world.

What Exactly Are Lasers?

A laser (an acronym for Light Amplification by Stimulated Emission of Radiation) is a device that generates a highly concentrated and focused beam of light. Unlike ordinary light sources like light bulbs, which emit light in all directions and across a broad spectrum of wavelengths, laser light is unique in three key ways:

- Coherence: Laser light waves are in phase with each other, meaning they move together in an organised, synchronised manner. This is what allows the laser beam to stay focused over long distances without scattering.

- Monochromaticity: Lasers typically emit light at a single wavelength or colour, which gives them the characteristic of being highly monochromatic. For example, a red laser emits light primarily at a single shade of red, whereas sunlight or standard bulbs emit many wavelengths (colours) of light simultaneously.

- Directionality: Lasers produce light that is highly directional, meaning it travels in a tight, very narrow beam that remains focused over long distances. This directional property allows lasers to be used for precision applications like cutting materials or performing delicate surgeries.

Brief History of Laser Development

The development of lasers is a fascinating journey that spans over a hundred years, marked by significant scientific breakthroughs and technological advancements. Here’s a brief overview of key milestones in the history of laser technology:

Early Theoretical Foundations (1917)

The origins of laser technology can be traced back to Albert Einstein, who published a paper in 1917 describing the principle of stimulated emission. In this work, he proposed that an atom could release photons when stimulated by external energy, laying the groundwork for the future development of laser technology.

First Masers (1953)

The first successful device to utilise the principle of stimulated emission was the maser (Microwave Amplification by Stimulated Emission of Radiation). Developed by Charles Townes and Arthur Leonard Schawlow, the maser operated at microwave frequencies and was capable of amplifying microwaves. As their work earned them the Nobel Prize in Physics in 1964, this breakthrough laid the groundwork for the development of lasers.

Birth of the Laser (1960)

The word "laser" is an acronym that stands for "Light Amplification by Stimulated Emission of Radiation." The acronym highlights the key principles behind how lasers operate, focusing on the amplification of light through the process of stimulated emission.

Coined by physicist Gordon Gould in 1957, it became widely recognised after Theodore Maiman built the first successful laser in 1960. However, the term became widely recognised and used after the first successful laser was built by Theodore Maiman in 1960. Maiman developed a ruby laser, which used a synthetic ruby crystal as the gain medium. This laser produced a coherent beam of red light, marking the official birth of laser technology.

Development of Different Laser Types (1960s-1970s)

Following Maiman's success, various types of lasers were developed:

Helium-Neon Laser (1960)

A gas laser that emitted a continuous beam of red light and became widely used in various applications.

Carbon Dioxide Laser (1964)

Developed by William C. Miller, this laser operated in the infrared spectrum and found applications in cutting and welding materials.

Semiconductor Laser (1962)

The first semiconductor laser, also known as a laser diode, was developed in the early 1960s. This compact and efficient laser diode made from gallium arsenide (GaAs) revolutionised the laser technology, leading to advancements in optical communications and consumer electronics.

Advancements in Laser Technology (1970s-1980s)

The 1970s and 1980s marked significant advancements in laser technology. During this period, fiber lasers were developed, enabling efficient light transmission and becoming essential for telecommunications. In addition, solid-state lasers, particularly neodymium-doped lasers, gained popularity due to their high power and versatility, finding applications in medicine, manufacturing, and research.

Medical Applications (1980s-Present)

Lasers began to be extensively used in the medical field during the 1980s. The introduction of lasik eye surgery, laser hair removal, and photodynamic therapy showcased the versatility and precision of lasers in treating various medical conditions.

Continued Innovation and Research (1990s-Present)

The 1990s and 2000s witnessed ongoing research and innovation in laser technology. Advancements in ultrafast lasers (lasers that emit light pulses in femtoseconds) enabled breakthroughs in fields such as material science and quantum computing. The advent of laser diodes further expanded applications in consumer electronics, including CD and DVD players, barcode scanners, and laser printers.

Common Misconceptions About Lasers

Here are some common misconceptions about laser technology and the realities that debunk them:

Lasers Are Only Used in Science Fiction

Many people think lasers are only fictional devices seen in movies and TV shows. But in reality, lasers are widely used in real life across various fields, including medicine, telecommunications, manufacturing, and entertainment. From laser eye surgery to barcode scanners, laser technology evidently plays a vital role in modern technology.

All Lasers Are Dangerous

There’s a belief that all lasers are harmful and they can cause instant damage. While some lasers, like those used in industrial cutting or military applications can be dangerous, many lasers, such as those used in pointers or printers, are safe when used correctly. Safety measures are in place to protect users, and proper handling minimises risks.

Lasers Can Cut Through Anything

People often think lasers can cut through any material effortlessly. But in fact, lasers can cut and engrave specific materials like metals, plastics, and wood. Their effectiveness depends on the type of laser, the power used, and the thickness of the material. Hence, not all lasers are suitable for all materials.

Laser Light Is Invisible

Some people believe that all laser light is invisible, which can lead to confusion. While certain lasers, like infrared lasers, emit light that is not visible to the human eye, many lasers, like those used in laser pointers and laser printers, emit visible light. The colour of the laser beam depends on the type of laser and its wavelength.

Lasers Are Just Fancy Flashlights

Many people think lasers are simply advanced flashlights that produce bright light. While both lasers and flashlights emit light, the light from a laser is coherent, monochromatic, and highly focused. Flashlights emit light in many directions and colours, making them fundamentally different from lasers.

All Lasers Are the Same

There’s a common belief that all lasers operate similarly. Lasers come in various types, each designed for specific applications. Whether they are semiconductor lasers, solid-state lasers, gas lasers, or fiber lasers, each has unique properties, uses, and operating principles.

Laser Technology Is Static and Unchanging

Some believe that laser technology has reached its peak and won’t evolve further. But the truth is, laser technology is continuously advancing. Researchers are exploring new types of lasers, such as ultrafast lasers and quantum-dot lasers, which could lead to innovative applications and improvements in existing technologies.

Core Components of a Laser

The core components of a laser are essential for its operation, allowing the device to generate a focused, coherent laser beam. These components work together to amplify light through the process of stimulated emission. The key components include:

Gain Medium

The gain medium is the material responsible for amplifying light. It can be a solid, liquid, gas, or semiconductor. When energy is applied to the gain medium, it excites the atoms or molecules within it, preparing them to emit photons. Some examples include:

- Solid: Ruby, Neodymium-doped YAG(Nd)

- Gas: Helium-neon (HeNe), carbon dioxide (CO₂).

- Liquid: Dye lasers.

- Semiconductor: Laser diodes.

Energy Source (Pumping Mechanism)

The energy source, or pump, supplies the energy needed to excite the atoms or molecules in the gain medium. Pumping can be achieved through various methods, such as:

Electrical pumping

Electrical pumping in laser technology is a method used to supply energy to the gain medium of a laser, exciting its atoms or molecules so they can emit photons. This process is crucial for the amplification of light in certain types of lasers, particularly semiconductor lasers (also known as diode lasers) and gas lasers.

Optical pumping

Optical pumping is a process used in laser technology to supply energy to the gain medium by using light from an external source. This method excites the atoms or molecules within the gain medium, causing them to move from a lower energy level to a higher energy level, which is essential for laser action.

Chemical pumping

Chemical pumping is used in chemical lasers, where a chemical reaction provides the necessary energy to excite the atoms or molecules in the gain medium. The energy source, whether chemical, electrical, or optical, is crucial for raising electrons in the gain medium to higher energy levels, enabling the process of stimulated emission to occur. Without this energy input, the laser would not be able to produce its characteristic coherent light.

Optical Cavity (Resonator)

The optical cavity consists of two mirrors placed at either end of the gain medium. One mirror is fully reflective, while the other is partially reflective, allowing some light to escape as the laser beam. The light reflects back and forth between the mirrors, passing through the gain medium multiple times and amplifying the light with each pass.

Output Coupler

The output coupler is a partially reflective mirror at one end of the optical cavity. It allows a portion of the light to escape as the laser output, while the rest continues to be amplified inside the cavity. The light that escapes forms the laser beam.

Laser Cooling System

Some high-power lasers require a cooling system to prevent overheating of the gain medium and other components. Cooling can be done through water, air, or other cooling mechanisms, depending on the type of laser and its power requirements.

How Do Lasers Work? The Science Behind Clean and Precise Laser Cuts

Lasers work by utilising the principles of quantum mechanics and optics to produce a highly focused and coherent beam of light, which enables quality and precise laser cutting of various materials. Here’s how the process unfolds:

Excitation of Atoms

The laser process begins with the excitation of atoms in the gain medium (solid, liquid, or gas) using an energy source (electrical, optical, or chemical). This excitation raises the electrons in the atoms to higher energy levels.

Photon Emission

When these excited electrons return to their lower energy levels, they release energy in the form of photons or particles of light. The emitted photons have the same wavelength, phase, and direction, making the light coherent and focused. Additionally, the identical properties of the emitted photons make sure that they can constructively interfere with each other, further enhancing the intensity of the laser beam.

Stimulated Emission

As these initial photons travel through the gain medium, they can stimulate other excited atoms to emit additional identical photons that mirror the first in energy, phase, and direction. This process, called stimulated emission, results in a rapid increase in the number of coherent photons, which as a result, creates a powerful laser beam.

Optical Cavity

The laser beam is further amplified in an optical cavity formed by mirrors placed at either end of the gain medium. One mirror is fully reflective, while the other is partially reflective, allowing some light to escape as a coherent laser beam. As the light bounces back and forth between the mirrors, it passes through the gain medium multiple times, gaining strength and coherence with each pass.

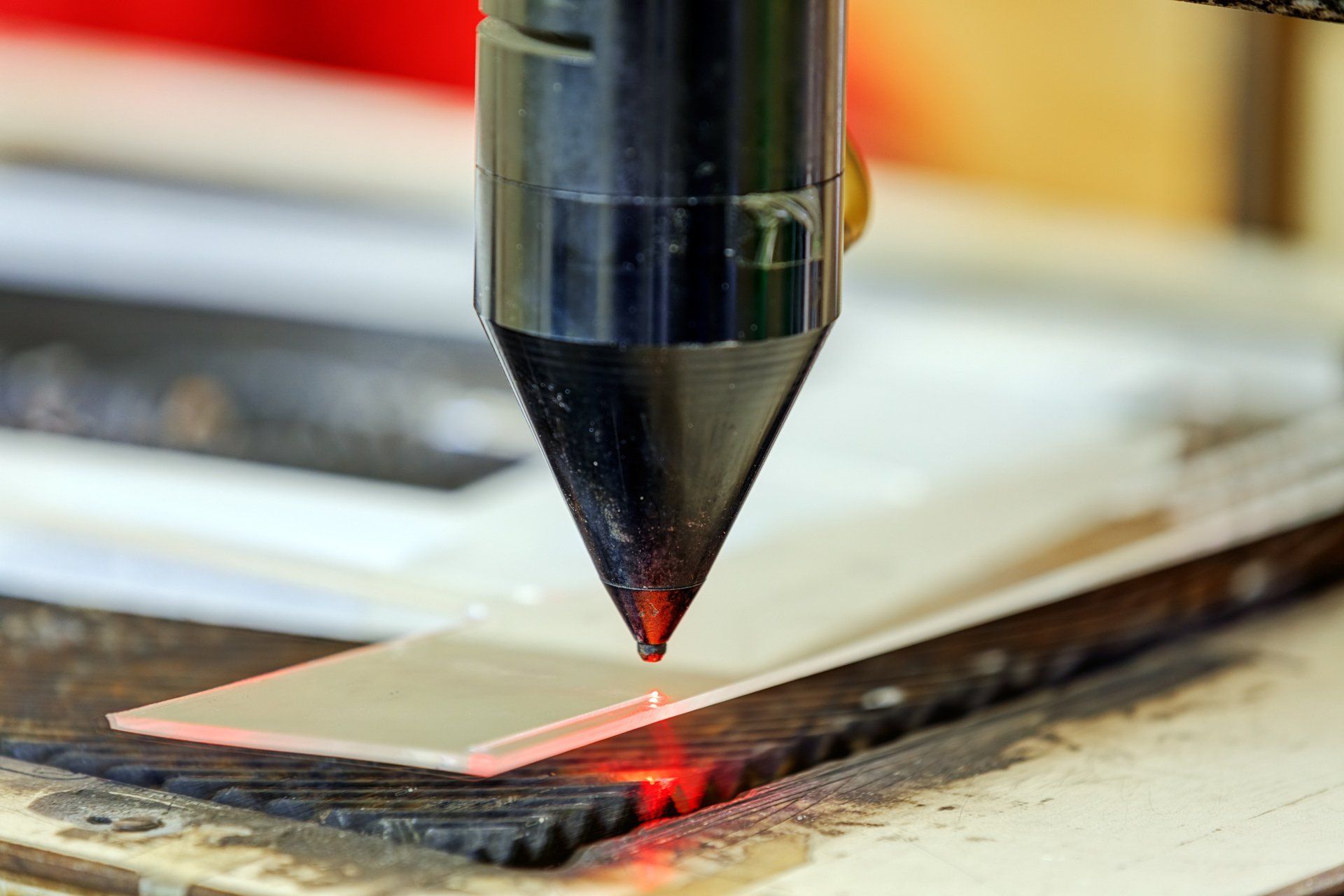

Laser Beam

After leaving the optical cavity, the laser beam is directed through a lens system that focuses the light into a narrow, intense beam. This increases the energy density of the laser beam, allowing it to concentrate on a small area of the material being cut. Significantly, high-quality laser beams maintain their focus over longer distances, producing clean cuts even in intricate designs.

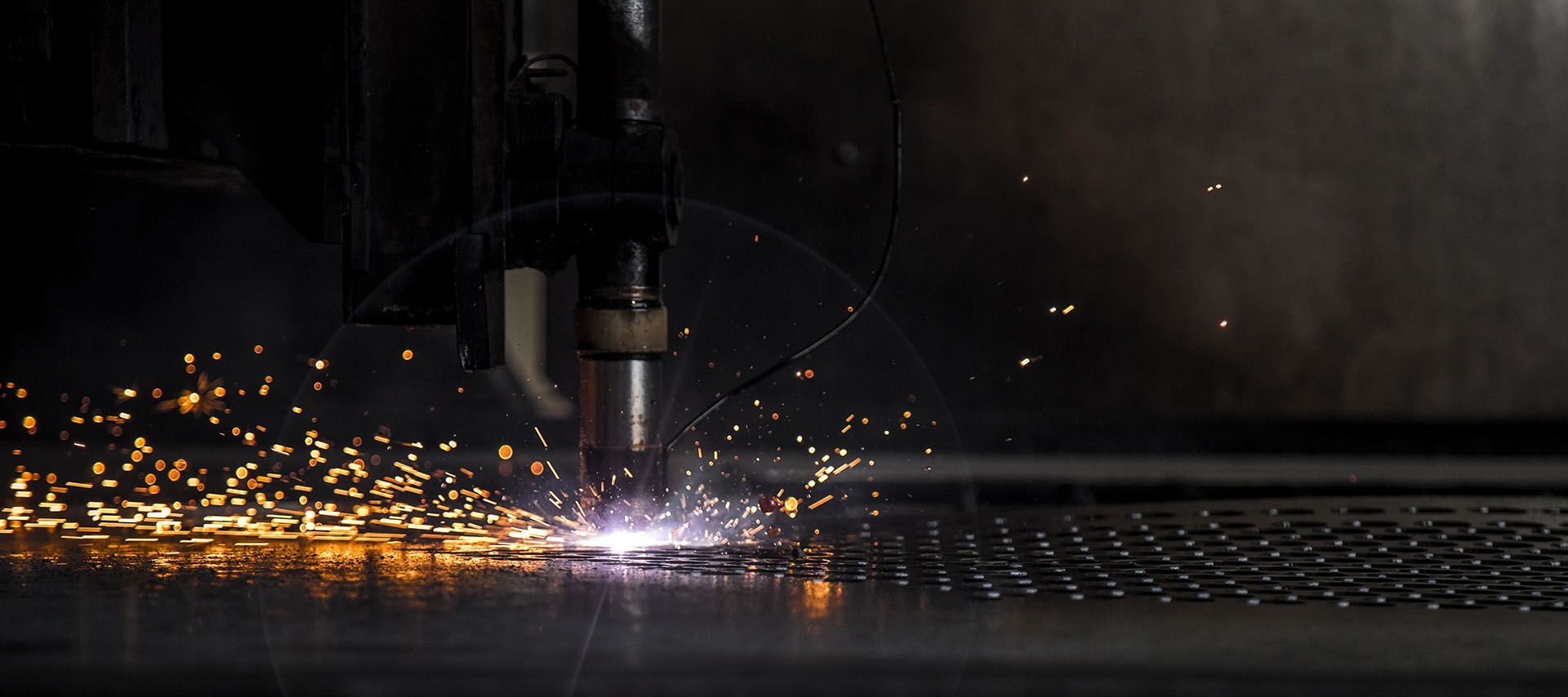

Surface Interaction

When the focused laser beam hits the surface of a material, it quickly raises the temperature at that contact point. Depending on the laser's intensity, it can vaporise, melt, or burn through the material. Hence, the way the cutting action works can differ based on the type of material and the kind of laser used.

- Vaporisation

For materials like plastics, the heat from the laser causes rapid vaporisation, enabling clean cuts without melting the material. This is particularly beneficial for intricate designs, as the vaporisation process leaves behind smooth edges and minimal residue.

- Melting and Blowing

For metals, the laser may melt the material, and a pressurised gas can blow away the molten metal, creating a clean edge. This process not only guarantees a precise cut but also minimises the formation of burrs or rough edges, which can occur with other cutting methods.

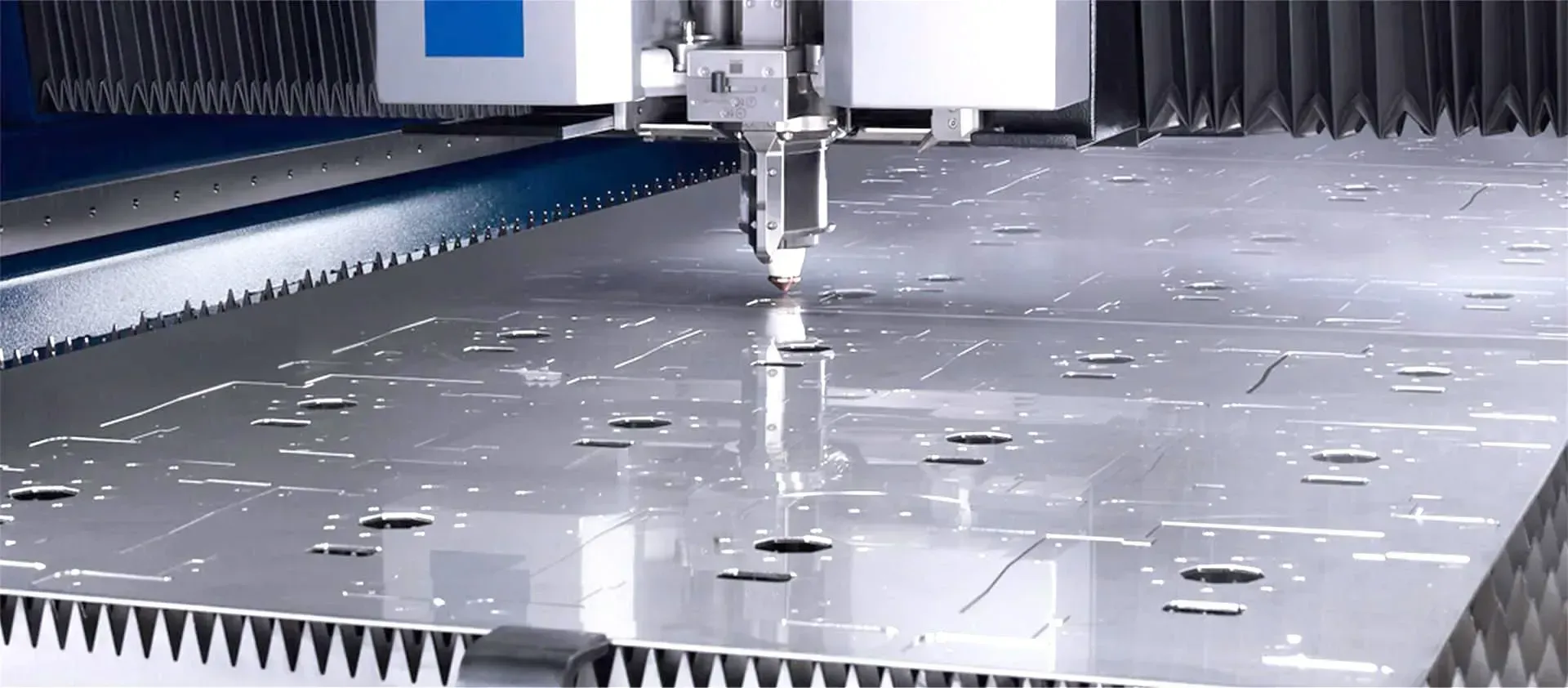

Precision and Control

Modern laser cutting systems use computer software to guide the laser head along exact paths for intricate designs. Operators can adjust the speed, power, and focus of the laser in real-time to suit various materials and thicknesses. This quick cutting minimises heat transfer, reducing the risk of warping or damaging nearby areas, resulting in clean, precise cuts with smooth edges.

Final Output

The result of this precise interaction between the laser beam and the material is clean edges that often require little to no additional finishing. This efficiency makes laser technology highly desirable in various industries, including manufacturing, aerospace, and electronics.

Types of Lasers

Here are some of the most common types of lasers:

Solid-State Lasers

Solid state lasers utilise a solid gain medium, such as Nd or ruby, for various applications, including medical and industrial uses.

Gas Lasers

Gas lasers use gases as the gain medium, with examples like HeNe lasers for holography and CO₂ lasers for cutting materials.

Dye Lasers

Dye lasers employ organic dyes as the gain medium, allowing for tunable wavelengths, often used in scientific research.

Semiconductor Laser (Laser Diodes)

Laser diodes utilise semiconductors and are commonly found in optical disc drives and fiber optic communication.

Fiber Lasers

Fiber lasers use doped optical fibers as the gain medium, known for high efficiency, frequently used in material processing.

Excimer Lasers

Excimer laser uses a combination of reactive gases to emit ultraviolet light, which is utilised in photolithography and eye surgery.

Free Electron Lasers

Free electron lasers produce light using a beam of electrons in a magnetic field, utilised in advanced scientific research.

Solid-State Fiber Lasers

Solid-state fiber lasers combine solid-state gain media with fiber optics for medical and material processing applications.

Quantum Cascade Lasers

Use quantum mechanics to emit mid-infrared light, employed in spectroscopy and environmental monitoring.

Real World Applications of Laser Technology

Lasers have a wide range of real-world applications across various fields. If you're curious about what industries use laser cutting, here are a few sectors:

Manufacturing

Many advanced manufacturing sectors use laser technology for precise cutting, welding, and engraving. With high accuracy, laser systems enable the creation of intricate components with tight tolerances. Additionally, lasers operate at impressive speeds, significantly reducing production times while minimising waste by optimising material usage. Their versatility also allows them to work with a wide range of materials, from metals to plastics, making them essential for various applications.

Industrial Applications

Diode lasers are employed for cutting, welding, engraving, and marking materials such as metals, plastics, and ceramics. Laser sintering technologies are used to create three-dimensional objects from powdered materials in additive manufacturing processes.

Telecommunications

Lasers transmit data over long distances through fiber optic cables, enabling high-speed internet and communication networks. Laser technology is used in Light Detection and Ranging (LiDAR) systems for mapping and surveying, providing precise distance measurements.

Consumer Electronics

Diode lasers are used in printers to produce high-quality images and text by using light to transfer toner onto paper. Lasers read the data encoded on optical discs by focusing light onto the surface and detecting the reflected signals.

Defence and Security

Research and development in directed-energy weapons are ongoing, where lasers can be used for disabling enemy equipment or missiles. Laser systems enhance security through perimeter detection and monitoring in sensitive areas.

Medical Applications

Laser technology is used for precise cutting and cauterising tissue in procedures like LASIK eye surgery, skin resurfacing, and tumor removal. They can also be used for optical coherence tomography (OCT), as well as for imaging tissues and detecting conditions like cancer.

Healthcare

Dye lasers play a critical role in medical procedures, including laser surgery, dermatology treatments, and dental applications. They are used for precise tissue removal, skin resurfacing, and treating various skin conditions like acne scars and pigmentation.

Scientific Research

Laser technology is utilised in various forms of spectroscopy to analyse materials and determine their chemical compositions. High-energy lasers are employed in experiments at particle accelerators and fusion research.

Construction

Lasers are used for leveling, aligning, and measuring during construction and surveying tasks. Tilt and compass sensors are often integrated into laser systems to ensure precise alignment and positioning during applications such as laser cutting and surveying. This makes it easier for construction workers to guarantee that structures are built to exact specifications.

Automotive

Laser technology assists in manufacturing processes, such as cutting and welding components, as well as in advanced driver-assistance systems (ADAS). In cutting applications, lasers provide precise and clean cuts in various materials, including metals, plastics, and textiles, allowing for intricate designs and reducing waste. Additionally, tilt and compass sensors contribute to ADAS by enhancing navigation, stability control, and detecting vehicle orientation.

Aerospace

Laser technology is used for material processing, inspection, and manufacturing of components in aircraft and spacecraft. In material processing, lasers enable precise cutting, engraving, and welding of lightweight yet strong materials such as aluminium and titanium, which are crucial for aerospace applications. This precision helps reduce weight while maintaining structural integrity, ultimately improving fuel efficiency and performance.

Entertainment

Laser technology is used in light shows, projectors, and displays, enhancing visual experiences in concerts and events. By producing vibrant colours and sharp images, lasers create stunning visual effects that captivate audiences and elevate performances.

Takeaway

Understanding the science behind laser technology reveals the remarkable precision and power that lasers possess in various applications. From manufacturing to healthcare and the industrial sector, innovative laser-based speed technology has transformed industries by enabling faster and more precise cutting and processing methods.

Whether you're exploring the theory for the first time or deepening your expertise, the science of how lasers work highlights how far this technology has come and the endless possibilities that lie ahead. At Hygrade Laser Profiling, we leverage advanced laser technology to provide cutting-edge solutions tailored to meet the specific needs of our clients. Our commitment to innovation guarantees that we stay at the forefront of the industry. For more information about our laser cutting services, get in touch with us today.

32 Harley Crescent Condell Park NSW, 2200 Australia

mail@hygradelaser.com.au

(02) 9791 1141

Find Us On: