32 Harley Crescent Condell Park NSW, 2200 Australia

Hygrade Laser Profiling

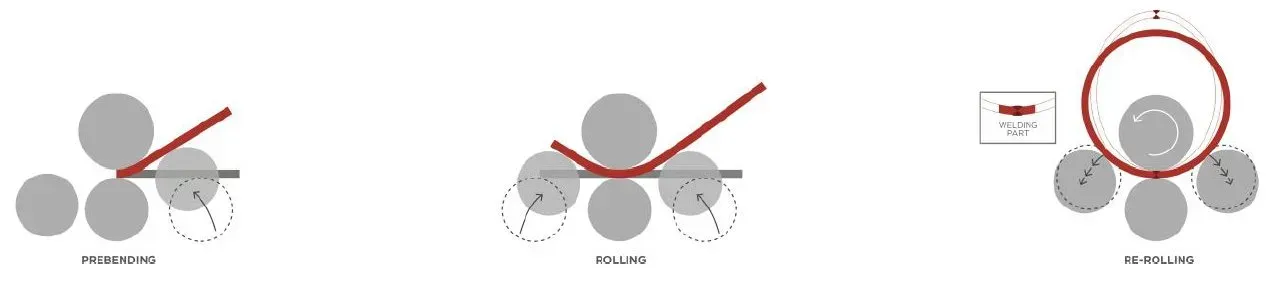

Metal Rolling

For over 30 years, Hygrade Laser Profiling has delivered expert metal rolling services with precision and efficiency. Our advanced technology ensures flawless shaping to your exact specifications, free from blemishes or deformities—delivering high-quality results every time.

Technology We Use

Our DAVI MCA 3028, engineered in Italy by a manufacturer with over 60 years of expertise, is renowned for its reliability and advanced technology. While we offer

Sydney laser cutting solutions, we also provide high-precision metal rolling with this state-of-the-art machine. It ensures efficiency, accuracy, and consistent quality, meeting the highest industry standards.

DAVI MCA 3028

The DAVI MCA 3028 sets the standard in metal rolling, offering exceptional accuracy and efficiency. Designed for high-performance applications, it can handle lengths up to 3100mm, with a top roll diameter of 280mm and a minimum rolling diameter of 310mm. Its Planetary Guide technology enables smooth, controlled rolling, ensuring precise results for even the most complex projects.

PERFORMANCES

| Width | Thickness | Internal Diameter | Yield | UTS | |

|---|---|---|---|---|---|

| Rolling | 3000 mm | 14 mm | 1400 mm | 260 Mpa | 400 Mpa |

| Prebending | 3000 mm | 10 mm | 1400 mm | 260 Mpa | 400 Mpa |

TECHNICAL SPECIFICATIONS

| 100% manufactured in Italy by | DAVI |

| Model | MCA 3028 |

| Number of rolls | 4 |

| Rolls length | 3100 mm |

| Top roll diameter | 280 mm - less deflecting thanks to Planetary Guide Technology |

| Bottom roll diameter | 260 mm |

| Side rolls diameter | 200 mm |

| Smallest possible diameter | 310 mm - thanks to Planetary Guide technology |

WHAT CLIENTS SAY ABOUT OUR METAL ROLLING SERVICES IN SYDNEY

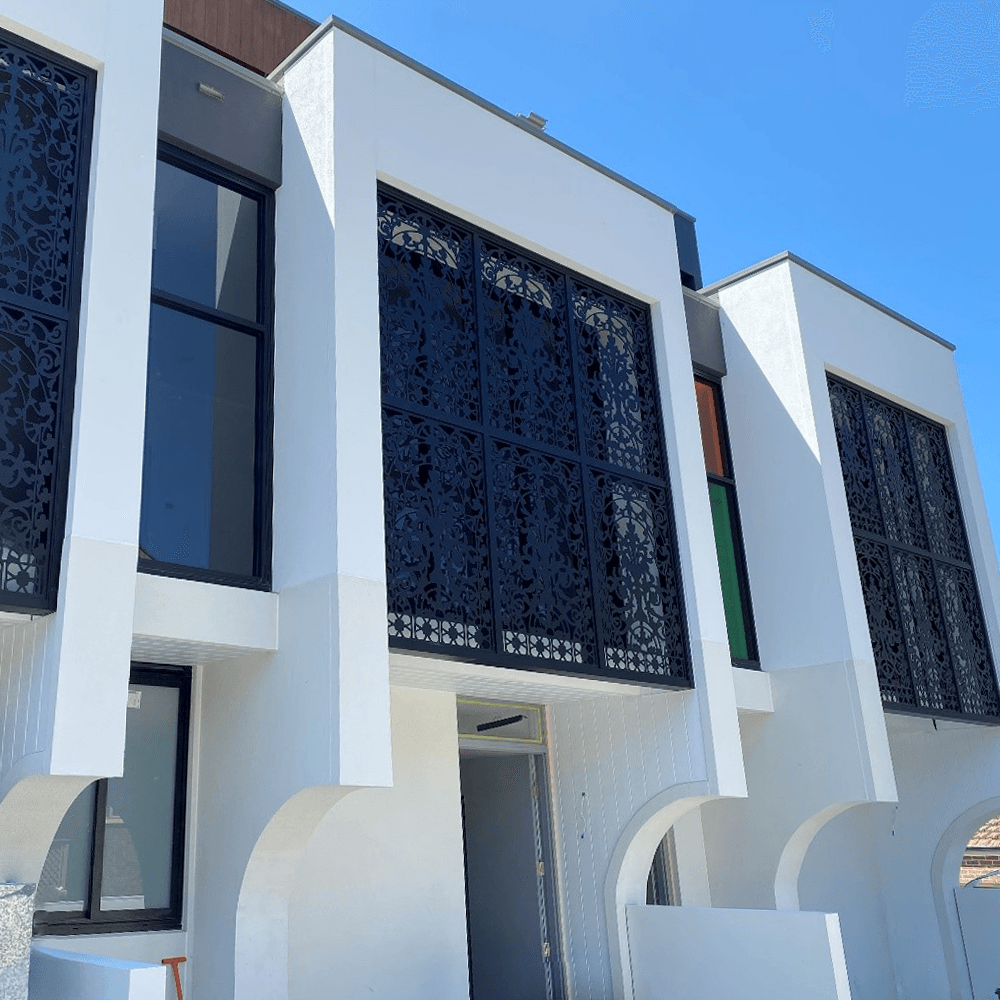

HYGRADE CAN MANUFACTURE YOUR NEXT PROJECT.

Contact Us Today!

Ready to learn more about our services?

We will work hard to provide you with the best service possible, and we guarantee that you will be satisfied with the end product.