32 Harley Crescent Condell Park NSW, 2200 Australia

Top 7 Industries That Use Laser Cutting Technology

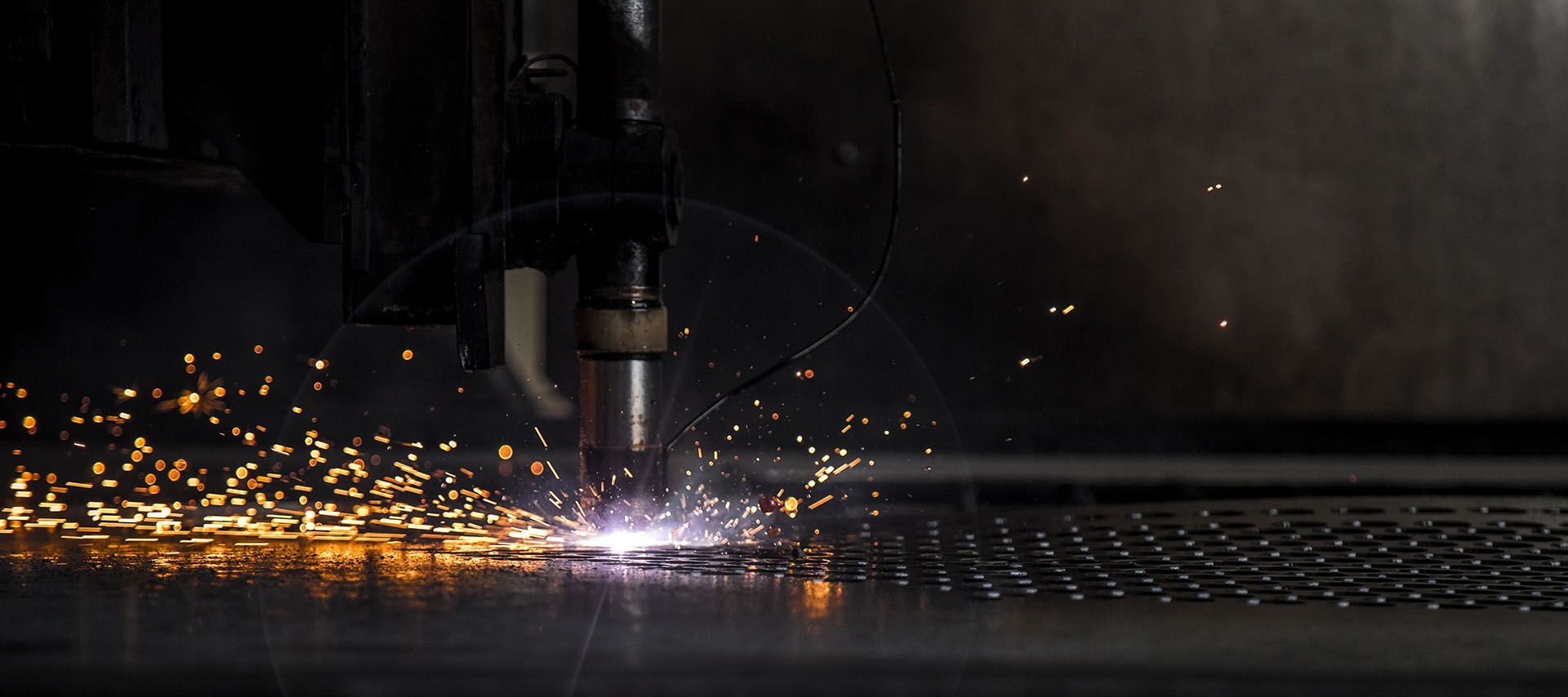

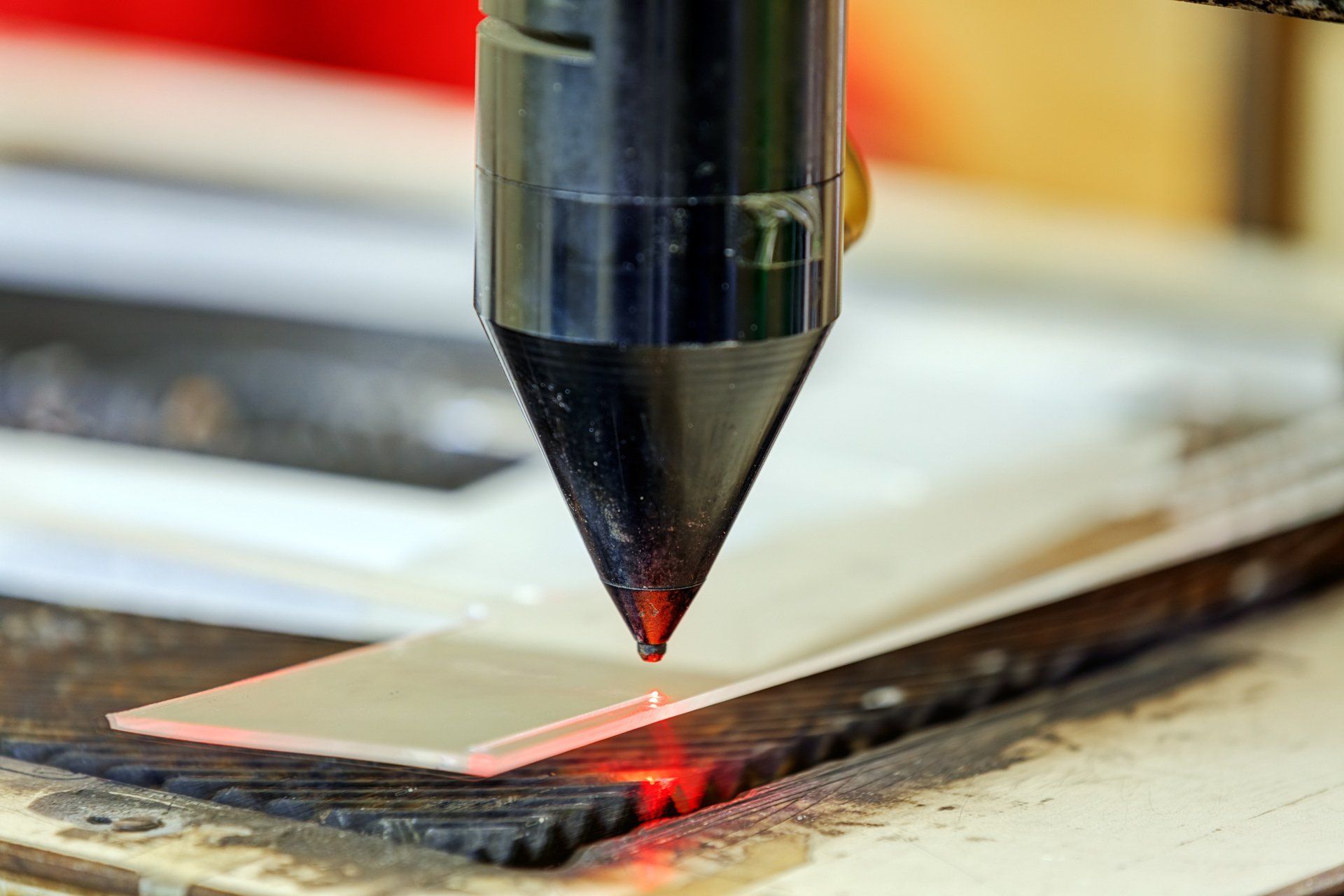

Laser cutting is undeniably one of the most popular and advanced methods to cut and shape metals. From automotive components to aerospace parts, laser cutters are often used in a variety of industries to deliver precise results for components that need high precision and accuracy.

As such, recognising the industries where laser cutting is prevalent not only promotes innovation, which leads to the creation of new products and solutions catering to specific industry needs, but it also helps to understand the importance of this technology in industry-wide manufacturing processes.

In this blog, we will be discussing the top seven industries that use laser cutting technology. These include the automotive, construction, electronics, medical, military, aerospace, and metalworking industries. If your business operates in one of these sectors and you're looking for laser cutting services, this blog is for you.

Which industries typically use a laser cutter?

Many industries use a laser cutter to cut a variety of materials including metals, plastic, and wood. Among these industries that utilise laser cutting include:

1. Automotive industry

When it comes to manufacturing vehicle parts, the automotive industry requires high precision and tighter tolerances. Not only due to the increasingly complex designs that vehicles have nowadays, but more importantly due to the safety standards that automotive companies have to uphold.

Before, vehicle components were created using stamping and die-cutting methods. However, since these methods were not accurate enough to fabricate complex designs, they were not able to meet the demands of the automotive industry.

This is where laser cutting comes into play as it effectively fulfills the standards of the automotive industry with its adaptability and ability to fabricate intricate shapes and designs. Having a high degree of precision in tube laser cutting, it has been used to manufacture a wide range of components from body panels to engine parts as well as other materials like die castings, suspensions, exhaust systems, brake systems, airbags, and many more.

Since then, the laser cutting process has become the most preferred technology for manufacturing automotive parts because of their accuracy, speed, and efficiency.

2. Construction industry

Like the automotive sector, the construction industry also relies on laser cutting to fabricate their structural components. Since most tools and equipment in the construction industry are usually large and complex, construction parts need to be cut delicately with precision and accuracy.

As such, laser cutting is responsible in the fabrication of large-scale projects for residential and commercial properties. These include bridges, tunnels, connection plates, base plates, and other materials such as large pieces of wood and composites that are used in other building developments.

Major steel construction projects typically involve thousands of these components. In such cases, laser cutting provides a significant edge with its speed and precision. Furthermore, tube laser cutting also finds extensive use in fabricating structural elements.

Laser cutting is not only renowned for its exceptional precision, but its high efficiency is what sets it apart from other traditional methods. Aside from working on materials made out of steel, aluminum, brass, and copper, laser technology is also used for accurate patterning, drilling, welding and engraving building components.

3. Electronics industry

In the electronics industry, laser machines are widely used to cut delicate electronic components with precision. Tube laser cutting is used to cut components such as circuit boards, enclosures, connectors, and heat sinks. The accuracy of tube laser cutting guarantees precise measurements and intricate designs in small components.

Unlike traditional methods, the laser beams in laser cutting will remain sharp regardless of how long they have been used. As a result, laser cut parts have cleaner, smoother, and more accurate edges. Among these delicate components include silicon wafers.

In other applications, laser engraving is used to permanently etch information onto electronic parts by drilling precise holes in printed circuit boards. Since there is no other way to identify a particular component but to look at the imprint, the electronics industry depends on laser engraving to mark and track parts. On top of these, laser welding has also become increasingly popular having the ability to join two pieces of metal without the use of heat or filler material.

4. Medical equipment industry

Medical devices and equipment such as X-ray and FMRI consist of complex components that require the use of various manufacturing technologies. Laser cutting finds application in fabricating several components for such machines, including their sheet metal housings. Furthermore, fiber lasers are also used in cutting a variety of materials involving bone, tissue, and plastic as well as in the manufacture of surgical instruments and other medical devices.

Medical equipment industries are undeniably one of the main beneficiaries of laser technology. As an industry that requires precision and intricacy of their components, tube laser cutting is able to provide these by manufacturing a range of medical devices. Among these include pacemakers, catheters, heart valves, stents, and many others.

Through material melting, the laser beam achieves a clean, accurate cut of the components. This technique is frequently used for crafting intricately designed parts, such as medical implants and those intended for internal use of the human body. Depending on the material being cut, some devices may require a CO2 laser for cutting stainless steel or fiber lasers for cutting devices made out of plastic.

5. Military industry

Laser cutting parts play a vital role across all military industries, whether on land, in the air, or at sea. But in particular, laser cutters are used frequently in crafting high-stress armor plating for military vehicles such as the HMMWV (Humvee).

Apart from this, laser marking and laser engraving techniques are also used across the defence sector to add text and graphics to a wide range of military gears and equipment including knives, flashlights, firearms, military vehicles, helicopter parts, and other tactical gears.

Following the identification requirements of the military property, machines and tools must be able to withstand harsh conditions and heavy usage. With laser marking and engraving techniques, the highest level of durability and accuracy can be achieved to meet these requirements.

Regardless of where it will be used, military components must be able to meet strict military standards and withstand harsh conditions and heavy usage. As such, laser cutting is widely used for various applications that produce armoured plates, creating permanent equipment markings, and manufacturing components for weapons systems.

Precision laser cutting guarantees optimal material usage which not only lowers waste and material expenses but also diminishes the likelihood of flaws and malfunction in the components.

6. Aerospace industry

The aerospace industry is one of the most demanding in terms of precision and quality assurance. Known for its extensive utilisation of precision engineering, the aerospace sector heavily relies on laser-cut metal for the construction of mechanical devices, airplane parts, and spacecraft components.

From cutting complex structures with intricate patterns, to laser marking onto metal surfaces and etching information on critical components of aircraft parts, laser marking ensures traceability, identification, and quality control among other methods. This is why it has become an integral part of the aerospace sector.

Generally, laser cutting primarily plays an essential role in the aerospace sector by fabricating component parts through processes like flatbed laser cutting, 3D laser cutting, and five-axis laser cutting. Aluminum alloy, which is one of the most commonly used materials in the industry uses laser cutters to achieve a flawless finish on highly intricate parts.

7. Metalworking industry

Metalworking refers to the process of shaping, manipulating, and cutting sheet metal into various shapes, components, or products. Using the different techniques and methods of laser cutting, the metalworking industry is able to achieve precision and accuracy in cutting even the most complex parts.

Some of these products include laser beam, sheet metal, columns, pipes, and tubing. These products are often used across diverse sectors including construction, automotive, and aerospace industries.

Furthermore, metalworking also uses laser engraving and laser marking to produce logos, labels, and markings on metal surfaces which can be done quickly and with high accuracy. Laser engraving is also used in the production of custom gifts, jewelry, tools, machine parts, and much more.

Takeaway

Laser cutting is one of the most important technologies in many industries today. With a high level of precision and accuracy, laser cutters can produce even and smooth laser cut parts at a more efficient and faster pace. From automotive to construction and electronics manufacturing, laser cutting allows companies to create intricate designs that would otherwise be difficult or impossible to produce using traditional tools.

By investing in high-quality laser cutting services, you can save time and money while ensuring accuracy and precision in your designs. At Hygrade Laser Profiling, we offer the best laser cutting services tailored to your needs. Whether your project needs laser cutting, metal forming, or machining services, we've got you covered. Get in touch with us today to see what Hygrade Laser Profiling can do for your business.

32 Harley Crescent Condell Park NSW, 2200 Australia

mail@hygradelaser.com.au

(02) 9791 1141

Find Us On: