32 Harley Crescent Condell Park NSW, 2200 Australia

What Can A Laser Cutter Make?

Want to know how a powerful beam of light can transform ordinary materials into intricate designs? In this blog, we explore the diverse capabilities of laser cutters, showcasing their ability to create intricate designs and precise cuts across different materials.

Whether working with wood, acrylic, metal, or other materials, a laser cutter provides endless possibilities for both enthusiasts and experts alike. Read this blog to explore the projects that laser cutting technology can produce, highlighting its impact in various industries.

What is laser cutting and how does a laser cutter work?

What is laser cutting? To answer this question, it's essential to delve into the core process. Laser cutting is a highly precise and versatile technology that involves using a laser to cut or engrave materials with incredible accuracy.

Laser cutters work by using a concentrated beam of light, generated by a laser, to cut through materials with precision. The process involves focusing a high-powered laser beam onto a small spot to generate intense heat, which then melts, burns, or vaporises the material in that spot. This controlled and concentrated application of heat allows the laser cutter to create clean, intricate, and detailed patterns that might be challenging to achieve through traditional cutting methods.

What types of materials can a laser cut?

Laser cutting is a versatile technology that can cut through various materials including:

Steel, Aluminum, Copper, Brass

Lasers are used for cutting thin metal sheets like steel, aluminium, copper and brass. With its capability to deliver highly precise cuts, it has been commonly used in producing intricate metal components for a range of applications which include the automotive, electronics, manufacturing, medical, architectural, construction, and aerospace industries.

Wood, Acrylic, and Paper

Laser cutting is commonly used for cutting and engraving wood. Plywood, MDF (Medium Density Fiberboard), and solid wood are some of the types of wood that can be processed by a laser cutter.

Acrylic sheets are also frequently laser-cut to create precise and intricate designs. Lasers produce smooth edges, making it a popular choice for various acrylic products such as signage, displays, and artistic projects.

Furthermore, laser cutting is ideal for creating intricate designs on paper or cardboard, commonly used in crafts, invitations, and packaging.

Textiles, Plastics, and Rubber

Laser cutting is employed in the textile industry for cutting intricate patterns in fabrics, leather, and other materials without fraying the edges.

Various plastics, including Acrylonitrile Butadiene Styrene (ABS), Polyethylene terephthalate (PET), and polycarbonate, can be laser-cut for applications ranging from prototypes to production parts.

Laser cutting can be used for cutting rubber materials, such as silicone rubber and neoprene, for gaskets, seals, and custom shapes.

What different functionalities does a laser cutter have?

Laser machines exhibit a range of diverse capabilities, including:

Precision Cutting

A laser cutter excels in creating detailed and intricate designs with high precision. Capable of achieving cutting accuracy at the scale of microns (μm) or even finer, it stands out for its exceptional precision. The degree of accuracy hinges primarily on the laser generator's type, the excellence of the optical system, and the precision of the motion control system.

Typically, laser-cutting machines demonstrate consistent accuracy within the range of ±0.05 to ±0.2 mm (0.002 to 0.008 inches), which is crucial for applications demanding intricate designs and stringent tolerances. In addition, laser technology also allows for sharp and clean edges, which is are attributes that are essentially useful in enhancing the overall quality of the cut materials.

Tube Processing

While laser cutting is known for cutting, it can also be employed in tube processing by utilising a laser beam to precisely cut through the walls of pipes and other cylindrical or tubular materials. The process involves loading tubes into a laser cutting machine equipped with a rotary axis, allowing for 3D cutting if needed. Design specifications are programmed into the CNC system, guiding the laser to create intricate shapes, patterns, or straight cuts with high precision. This method is versatile, applicable to various materials, and commonly used in industries like automotive, aerospace, and construction due to its efficiency and minimal material waste.

Laser Marking

Laser marking is a versatile technique that offers a non-contact and permanent solution for adding information, such as serial numbers, barcodes, or dates, to a wide range of materials. Laser markings are typically resistant to wear, corrosion, and fading, which is why it's ideally used in applications where product tracking, quality control, or compliance with industry regulations is essential. With its ability to create highly detailed and durable markings on surfaces without causing any harm to the material, it is commonly used in manufacturing, electronics, and automotive industries.

Engraving Capabilities

A laser cutter or a laser engraver uses a laser beam to remove or mark the surface of materials. Often, a laser engraver comes equipped with adjustable power settings and focus controls, allowing users to tailor the intensity and depth of the laser beam based on the specific material being processed. With these capabilities, laser engraving is commonly used in products that require customised text, images, logos, or decorative patterns.

Laser Etching

While laser etching and laser engraving both use a high-powered laser cutter in marking a material like metal or glass, there is a significant difference with the way they interact with the material's surface. Laser etching involves removing a thin layer from the material's surface in order to create a subtle and smooth design. With this technique not exceeding 0.001 inches on the material's depth, laser etching is recognised for adding intricate patterns without compromising the material's integrity.

Versatility in Material Selection

Whether the material you are about to cut involves wood, acrylic, leather, paper, or metals, a laser cutter has the precision and speed to create intricate designs and detailed patterns across a wide range of materials. Additionally, its non-contact process reduces the risk of material contamination, ensuring a clean and precise cut every time. Whether you are crafting prototypes, custom signage, or intricate art pieces, laser cutting provides a level of accuracy and intricacy that is hard to achieve with traditional cutting methods.

Prototyping and Manufacturing

Laser cutters are often used in prototyping processes because they allow for quick and precise fabrication of design concepts. Whether the item requires intricate details or simple shapes, a laser cutter can accommodate a wide range of design complexities that are useful in creating prototypes that accurately represent the final product. This aids in the visualisation and refinement of designs before mass production. Furthermore, it is used for scaling up production as it can produce the same items quickly while maintaining consistency and quality.

Customisation and Personalisation

Businesses often use a laser cutter or a laser engraving machine to create various intricate designs. In addition, it also enables the creation of unique and personalised gifts, laser engraved items and customised accessories. Whether it's for production of promotional merchandise or corporate gifts, companies can use laser engraving to imprint their logos, messages, or brand names on a variety of items. This not only enhances brand visibility but also adds a sophisticated and professional touch to promotional materials.

Variable Power and Speed

A laser cutter basically allows users to adjust the power and speed of the laser beam. This feature is crucial for achieving different results on various materials. By adjusting these parameters, users gain precise control over the laser cutting or engraving process, allowing them to customise it according to the distinct properties of each material.

For instance, when working with metals, adjusting the power and speed helps achieve clean and accurate cuts without causing excess heat. As a result, the risk of distortion is minimised. On the other hand, when engraving intricate designs on delicate materials, lower power settings and slower speeds are often preferred to ensure intricate detailing without compromising the material's integrity.

Auto-Focus and Z-Axis Control

Some lasers have auto-focus features or Z-axis control, enabling them to automatically adjust the focus based on the material's thickness. With multi-axis control features, these machines can perform intricate tasks such as bevel cutting, 3D engraving, and even adding textured effects. The precision-driven nature of CNC technology brings a level of sophistication to the cutting process, making it ideal for industries where accuracy and intricate detailing are important.

Computer Numerical Control (CNC) Integration

Most laser machines are equipped with CNC technology that allows them to be controlled by computer programs. This not only facilitates precise and intricate designs but it also allows replicating designs accurately. Moreover, the user-friendly interface of CNC technology allows operators to easily program the machine through computer software, making adjustments and customisations easy.

What types of projects can a laser cutter produce?

Here are some laser cutter projects that showcase the diverse applications of laser cutting and laser engraving.

Laser cut clocks

Laser-cut clocks are one of the most common products that can be fabricated using a laser cutter. Through precise laser cutting technology, clocks not only serve as timekeeping devices but also artistic pieces. Whether it's minimalist, geometric patterns or intricate, ornate designs, laser-cut clocks can be perfect to display in the home, office, or in public spaces, demonstrating the fusion of technology and artistry in modern design.

Laser cut screens

Laser-cut screens are decorative or functional panels that are created using laser cutting technology. These panels can serve both decorative and practical purposes, enhancing spaces with intricate patterns while also acting as functional barriers, dividers, or privacy screens. The process for creating this involves directing the laser beam through the material to create intricate patterns or designs. This technology is commonly used for cutting a variety of materials, including metals, wood, acrylic, and more.

Outdoor furniture

Laser cutting is known for its precision and versatility. When applied to weather-resistant metals, it can produce functional and aesthetically pleasing elements for public spaces. From intricately designed benches and decorative trash receptacles to uniquely shaped bike racks and informational signage, laser-cut outdoor furniture adds a touch of sophistication and creativity to urban environments. Hygrade has fabricated a range of street and park furniture across Sydney, Brisbane, Melbourne, Perth and Adelaide.

Engineered products for public and community spaces

Public and community spaces can also benefit from laser cutting. Various laser cut products that you see in public spaces include intricately designed laser cut shower panels, wall mounted drinking fountains, and many more. These laser-cut elements not only enhance the aesthetic appeal of the surroundings but also serve functional purposes, such as providing innovative and visually striking solutions for everyday amenities. The versatility of laser cutting technology allows for the creation of functional yet artful elements, promoting a sense of community and fostering a welcoming atmosphere in public spaces.

Staircases and balustrade

Laser cutting is also applicable for large projects. In residential homes and commercial buildings, laser cut components are also used to create custom staircases and balustrades. With precise laser cutting and engraving, intricate details can be incorporated into these structural components. Whether it's crafting ornate patterns or geometric shapes, laser-cut components add a touch of sophistication and uniqueness to the overall aesthetic appeal of interior spaces.

Architectural pieces

Today, architects and designers use laser cutting to create detailed and complex patterns, shapes, and components for building facades, exterior decorations, and structural elements. The speed and accuracy of laser cutting not only enhance the efficiency of production but also allow for the realisation of intricate and customised architectural pieces that may be challenging or impossible with traditional methods. One of Hygrade's known architectural pieces is located at the corner of Clarke St and Nithsdale St in Sydney.

Aboriginal Garden

Laser cutting can be used to enhance the artistic and cultural elements of the space. For example, intricate laser-cut metal panels or sculptures featuring traditional Aboriginal patterns and symbols can be strategically placed throughout the garden. These laser-cut artworks may depict stories, narratives, or symbols that hold cultural significance. These informative displays can incorporate Aboriginal languages, promoting language preservation and cultural awareness. One of Hygrade's notable creations include the Aboriginal Garden at the Royal Prince Alfred Hospital in Sydney.

Laser cut brass components

Laser-cut brass components are precision-engineered parts created using advanced laser cutting technology on brass sheets. This process allows for intricate and detailed designs with exceptional accuracy and clean edges. Brass, a durable and corrosion-resistant alloy, adds a touch of elegance to the components. The versatility of laser cutting in brass components makes it popular for both functional and ornamental purposes, as it showcases a perfect blend of craftsmanship and modern manufacturing techniques. One of Hygrade's notable creations include the laser cut brass components of the Judith Neilson Auditorium.

Laser cut art

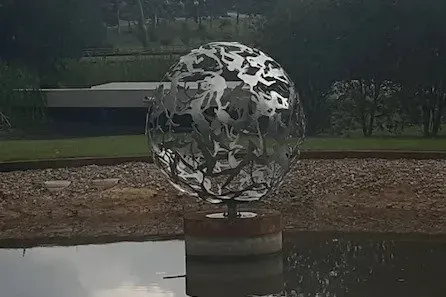

Today, more and more artists are choosing to use laser cutting and laser engraving as their preferred methods of creating intricate and precise artworks. From sculptors crafting detailed sculptures to graphic designers etching intricate patterns, the versatility of laser cutting and engraving has opened up new avenues for creative expression. Through these techniques, artists are able to produce intricate laser cut art that were once impossible to achieve through traditional methods.

Designed using stainless steel, this sculpture by Michael Snape (as shown in the image) depicts the impressive features of the TRUMPF TruLaser, Hygrade's advanced laser cutter. Known for its swift, precise, and efficient project execution, the TRUMPF machine excels in laser cutting various materials.

Laser cut signs

Another fabricated item that can be produced through laser cutting and laser engraving are nameplates and plaques. These laser engraved plates, created with advanced laser engraving machines, serve as distinctive signage for properties within a given estate. The process allows for customisation, enabling the incorporation of estate names with sharp, clean lines and a polished finish. This technique not only ensures a visually appealing aesthetic but also showcases the efficiency and versatility of laser cutting in producing personalised and durable estate identification plates. One of Hygrade's notable creations include the laser engraved nameplate of Braycharlo Estate in Oakdale, NSW.

Wall art

Today, laser-cut wall art has been embraced as a contemporary and sophisticated form of interior decoration. With its precision and versatility, laser cutting technology allows artists and designers to create intricate patterns, geometric designs, or personalised artworks. Artists and designers can experiment with a wide array of materials, such as wood, acrylic, and metal, to produce visually stunning wall art pieces that captivate viewers. From abstract sculptures to personalised signs, laser-cutting techniques contribute significantly to the diversity and creativity seen in contemporary wall art.

Laser cut jewelry

Modern jewelry production has embraced advanced technology, with laser cutting and laser engraving becoming pivotal techniques. Laser cutting enables precise and intricate designs, allowing for intricate patterns and shapes in various materials such as metal, wood, and acrylic. Simultaneously, laser engraving adds a personalised touch, creating detailed and customisable designs on the surface of laser cut jewelry pieces. With the precision of laser cutting, different jewelries can be produced, such as earring pendants, charms, and personalised details for bracelets and necklaces.

Laser cut toys

Laser cutting is often used in the production of toys due to its versatility and ability to create elaborate designs, smooth edges, and complex geometric shapes. From puzzle pieces, personalised wooden train set, to action figures, the application of laser cutting in toy manufacturing has revolutionised the industry. The precision offered by a laser cutter allows for the creation of detailed and precisely fitted components, ensuring that each piece seamlessly integrates into the final product. This level of accuracy is especially beneficial for small-scale toys where precision is important.

Personalised gifts

Aside from using a laser cutter, some personalised gifts can be effortlessly crafted using a laser engraver. Laser engraved gifts will definitely add a unique touch to special occasions. Whether it's customising wooden photo frames, engraving names on metal jewellery, or personalising glassware with intricate designs, the precision of a laser engraver ensures a high-quality and sentimental touch to the gift-giving experience. The ability to etch text, images, or even detailed artwork onto various materials makes laser engraving a versatile process for creating a unique, personalized and heartfelt gift.

Personalised home decor

Whether it's a special occasion or simply a desire to enhance the aesthetic appeal of living spaces, laser cutting and laser engraving both offer a wide range of possibilities for crafting one-of-a-kind home decor items. The ability to cut and engrave various materials, including wood, acrylic, leather, and even fabric, further expands the creative possibilities for laser-cut decorations. As technology advances, these technique also incorporates laser engraving to add intricate details and personalised touches to decorations. Laser engraving enhances the overall aesthetic by adding fine lines, textures, or custom designs to the surfaces of materials, elevating the visual appeal of the finished laser-engraved product.

Automotive parts

Laser cutting automotive components guarantees precise cuts according to specifications. It allows rapid and accurate adjustments if needed, which is crucial as modern cars require intricate cutting of smaller parts. This precision of laser cutting is especially advantageous in meeting the demands of increasingly advanced automotive designs. Moreover, laser cutting ensures a clean and smooth finish on the cut edges, reducing the need for additional finishing processes. This not only saves time but also enhances the overall quality of the automotive components.

Semiconductor parts

Laser cutting provides adaptable, cutting-edge machining to fulfill the most challenging specifications in semiconductors. It enables the precise and flexible cutting of both simple and intricate parts. The process is contact-free, ensuring no marks or material contamination. The resulting high-quality cuts eliminate the need for extra finishing, and the versatility extends to cutting various materials, often eliminating the requirement for additional post-processing. Furthermore, laser engraving can be employed in applications like marking or labelling semiconductor components, such as adding serial numbers, date codes, or other identification marks.

Surgical tools and prototypes

In the medical industry, laser cutting plays a crucial role in meeting the exacting standards required for surgical devices. The technology's ability to achieve intricate designs and tight tolerances is essential for ensuring the precision needed in medical instruments. Additionally, the non-contact process minimises the risk of contamination, which addresses the stringent sterility requirements of medical applications. Common medical devices that can be laser cut include metal tubes for stents, polymer tubes for catheter shafts, ceramics for the insulating components of bipolar laparoscopic instruments or precious metals such as platinum or gold for X-ray marking components.

Takeaway

As technology continues to advance, the potential applications of laser cutting machines will likely expand, making them increasingly essential for those who value precision, efficiency, and innovation in their projects. That's why choosing the right laser cutting service is important if you want to ensure the best results.

At Hygrade Laser Profiling, we offer the best laser cutting services in Sydney tailored to the needs of our local clients. Our team is well-versed in a wide range of laser cutter projects, offering expertise in crafting prototypes, manufacturing intricate parts, and creating custom or personalised tools. Get in touch with us today to get a quote.