32 Harley Crescent Condell Park NSW, 2200 Australia

The Many Variables of Cutting with Gas During Aluminium Laser Cutting

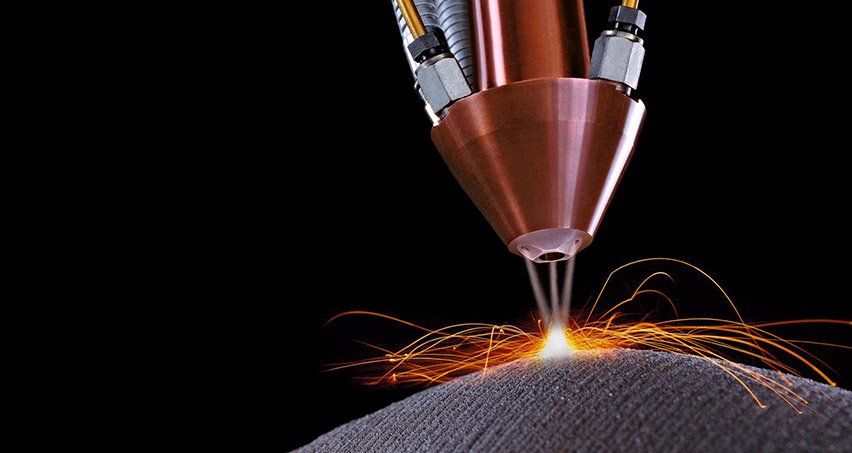

Gas propellants for aluminium laser cutting can often be a debated topic. Many fabricators have their preferences based on certain variables. Often, the variable that is considered is the type of material and thickness, but there are some other factors that should be examined when choosing an assist gas for laser cutting.

Assist gas is one of the most overlooked areas for manufacturers as it can be quite intimidating for an operator. Considerations like pressure, flow, and delivery methods all need to be assessed fully. Fabricators need to give consideration to production volume, the total number of lasers being used, environment in the shop, and finish for the material surface.

Assist Gas for Aluminium Laser Cutting

When it comes to aluminium laser cutting, nitrogen is the way to go. Many shops will incorporate either oxygen or air into their processes, but when it comes to aluminium, nitrogen offers the most benefits. Unfortunately, nitrogen does come with a higher price tag which is why it keeps some shop owners from using it and turning to oxygen instead. However, with the ability to cut faster, cleaner, and creates a cleaner surface than other assist gases.

As with choosing the right gas, there are other variables that can make a large difference in aluminium laser cutting. Assist gas setup and storage can be problematic as well for shop owners. The storage and delivery mechanisms must be devised based on the individual needs of the fabricator. There can be many interruptions to workflow if storage and delivery are not appropriate for the process in place. For instance, if the tanks are small, work stops frequently to change them out. These may be unintended time constraints that are unrecognised in a shop.

When it comes to delivery mechanisms, one of the most streamlined options is a shared delivery system so that there is no redundancy in the equipment. It’s time, money, and a space saver that can easily transform a fabrication shop. Assist gas is a necessary consumable in a fabrication shop, and it must be done right for aluminium laser cutting to be effective.

RECENT POSTS