32 Harley Crescent Condell Park NSW, 2200 Australia

Blog Layout

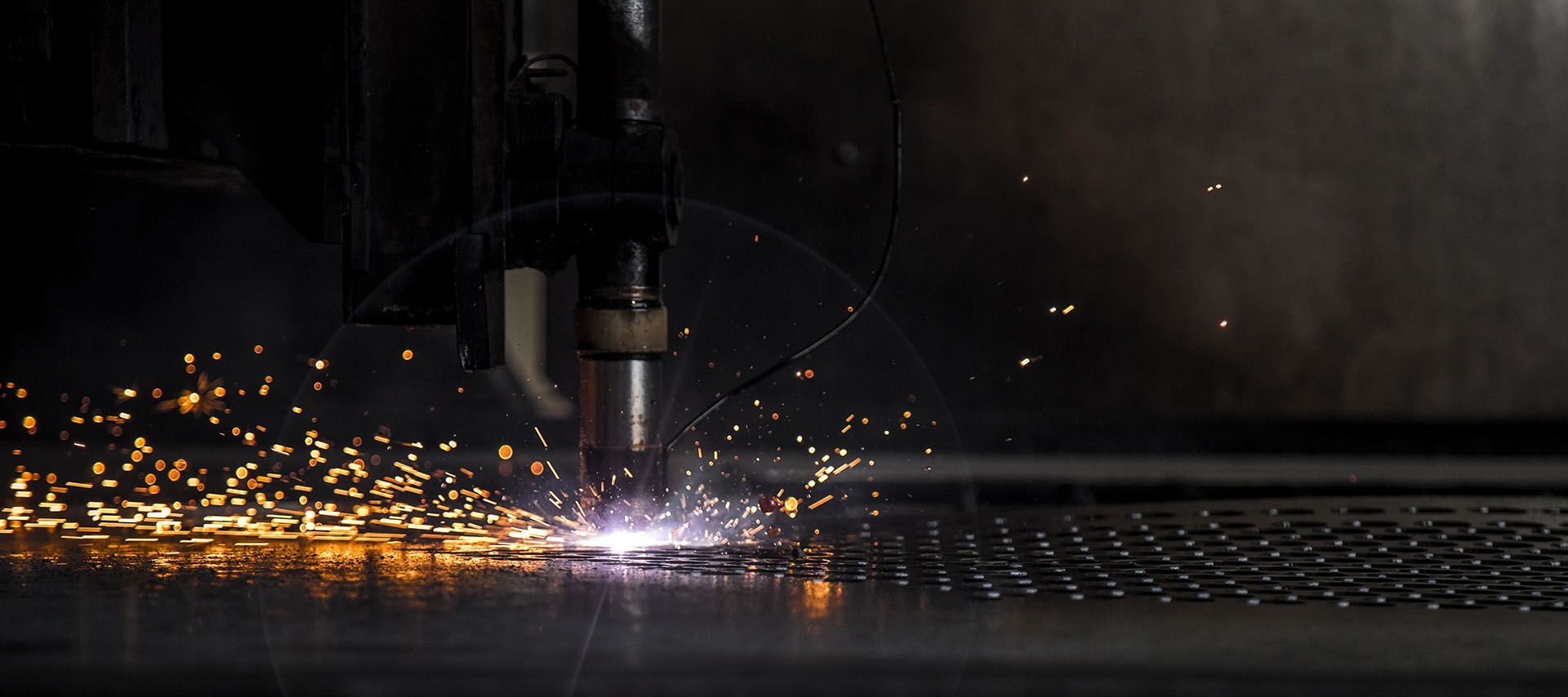

TRUMPF Makes Improvements to Machinery for Brass and Copper Cutting

As an industry leader, TRUMPF is responsible for making large, industry-wide changes that have an immense impact on many fabricators worldwide.

One of the biggest innovations that has really taken hold are fiber lasers. This laser cutting technology is enabling fabricators to reduce error rates and improve tolerances.

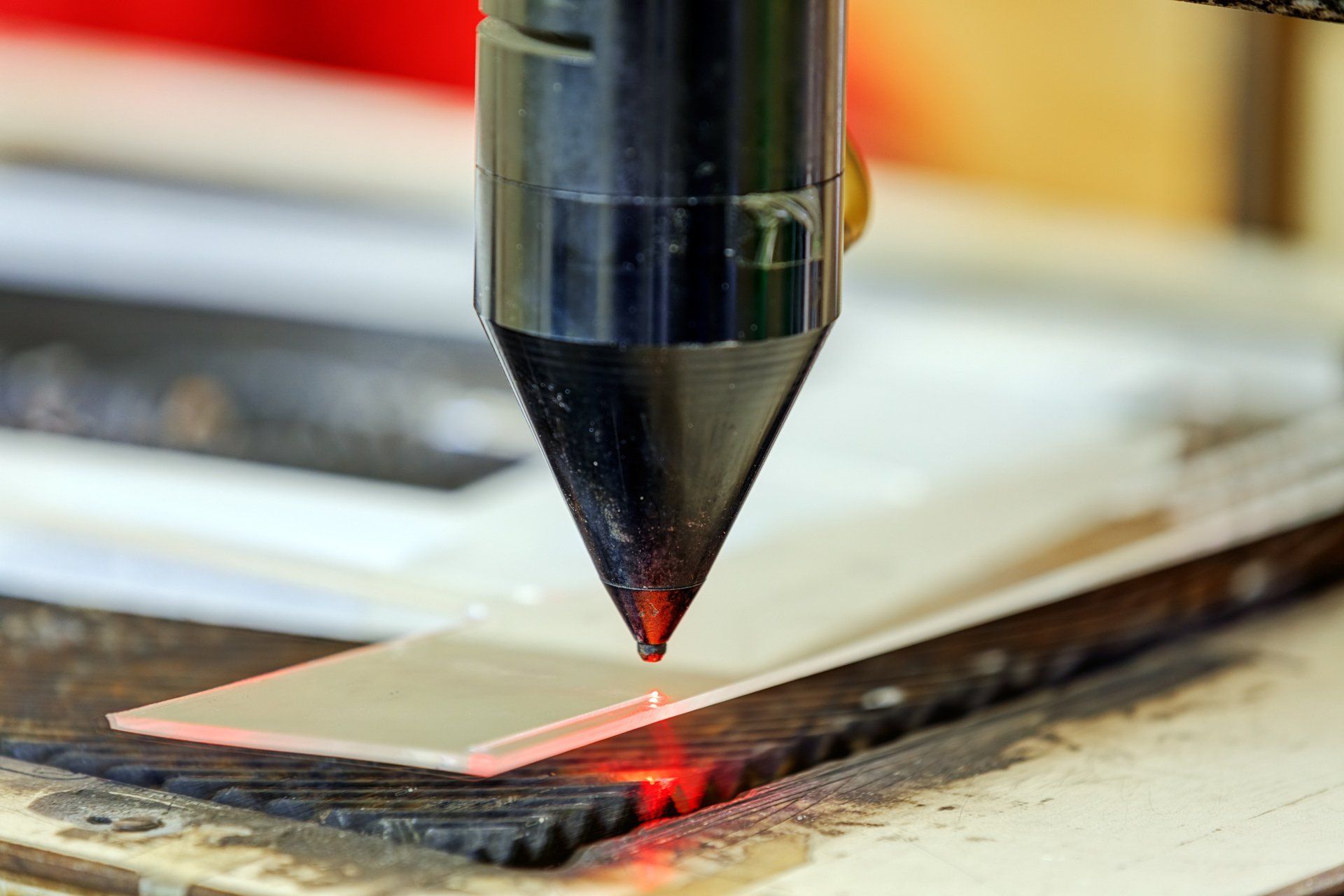

Fiber lasers like TRUMPF’s TruLaser 5030 Fiber is an economical solution for high productivity. Predominately a brass cutter, the machine also cuts copper along with variety of materials, giving the manufacturer more versatility.

Conventional cutting of both of these materials can be quite difficult. However, with TRUMPF’s innovative technology, laser cutting of brass or copper is as simple as pressing a button.

With its high power and part quality, the fiber laser can cut material thicknesses of up to 20mm.

Offering laser cutting services for brass and copper is a new venture for Hygrade Laser Profiling and because of their new fiber laser from TRUMPF they are able to provide this additional service to their customers.

TRUMPF’s continual investment in enhancing and creating machinery for manufacturers is enabling Australian job shops like Hygrade Laser Profiling to tap into market areas they never thought possible.

For more information on Hygrade’s brass and copper laser cutting services, contact us for a quote.

RECENT POSTS

Hygrade Laser Profiling has over 30 years professional experience in producing quality manufactured products through laser cutting, with great service that meets the needs of our local clients.

32 Harley Crescent Condell Park NSW, 2200 Australia

mail@hygradelaser.com.au

(02) 9791 1141

Find Us On: