32 Harley Crescent Condell Park NSW, 2200 Australia

Additive Manufacturing Opens New Possibilities

Opening up endless possibilities, Additive Manufacturing is transforming the way components are built. With nothing more than powdered material and the precision of laser light, additive manufacturing technology has defied conventional manufacturing.

Additive Manufacturing, or Additive Layer Manufacturing, describes technologies that create 3D objects by adding layer-upon-layer various materials such as metal, plastic, concrete and so on. Using computer-aided design (CAD), additive manufacturing enables the production of objects in precise geometric shapes. This innovative manufacturing process incorporates many technologies such as 3D printing, Rapid Prototyping (RP), Direct Digital Manufacturing (DDM), layered manufacturing and additive fabrication.

In general, only powder and laser light are used to form components. Until recently, ablation and forming methods have outweighed Additive Manufacturing in the industrial production line. This shift aligns with the advancements in modern manufacturing; where traditional methods could not produce geometrically complicated objects, Additive Manufacturing shows that this can be done, without using any tools or machinery. This form of manufacturing process is exceptionally advantageous when producing prototypes and unique pieces of precise geometric shapes. Ultimately, the user benefits from the freedom to design any shape they choose.

The Different Processes of Additive Manufacturing

Additive Manufacturing consists of several unique processes, each having their own set of specifications, such as:

Binder Jetting

The binder jetting process basically uses powdered material for building and a liquid binder to act as an adhesive. During the binder jetting process, a 3D printing-style head moves along the X, Y, and Z axes to deposit successive layers of powdered material and the liquid binder. Following each layer, the printed object is lowered on its build platform.

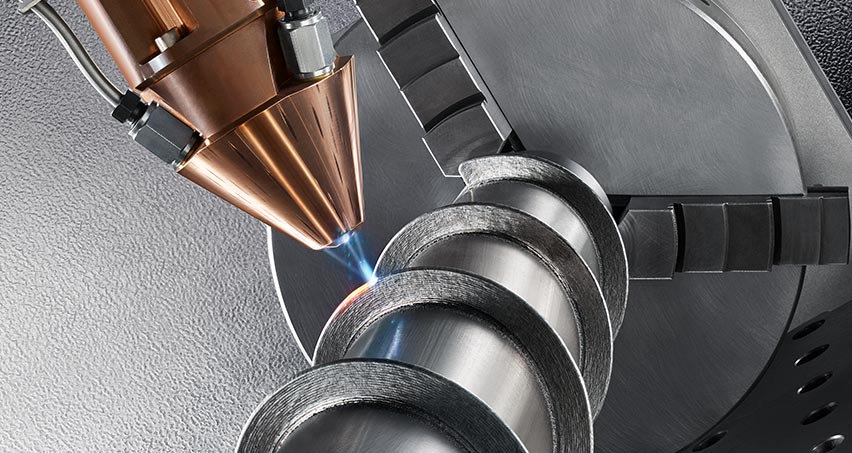

Directed Energy Deposition

Directed energy deposition is a 3D printing process that can be used with a wide variety of materials including ceramics, metals and polymers. In this process, a heat source such as a laser, electric arc, or an electron beam gun is affixed to an arm and moves horizontally, melting wire, filament feedstock, or powder as the bed moves vertically to facilitate the buildup of material.

Like other additive manufacturing processes, directed energy deposition systems can add material to pre-existing components, making them suitable for repair purposes. Additionally, they can also be utilised to construct new parts as the need arises.

Blown Powder Process

The blown powder directed energy deposition process is capable of depositing fully dense metallic materials on both flat and curved surfaces, making it well-suited for repair and hybrid manufacturing processes that involve both additive and subtractive manufacturing.

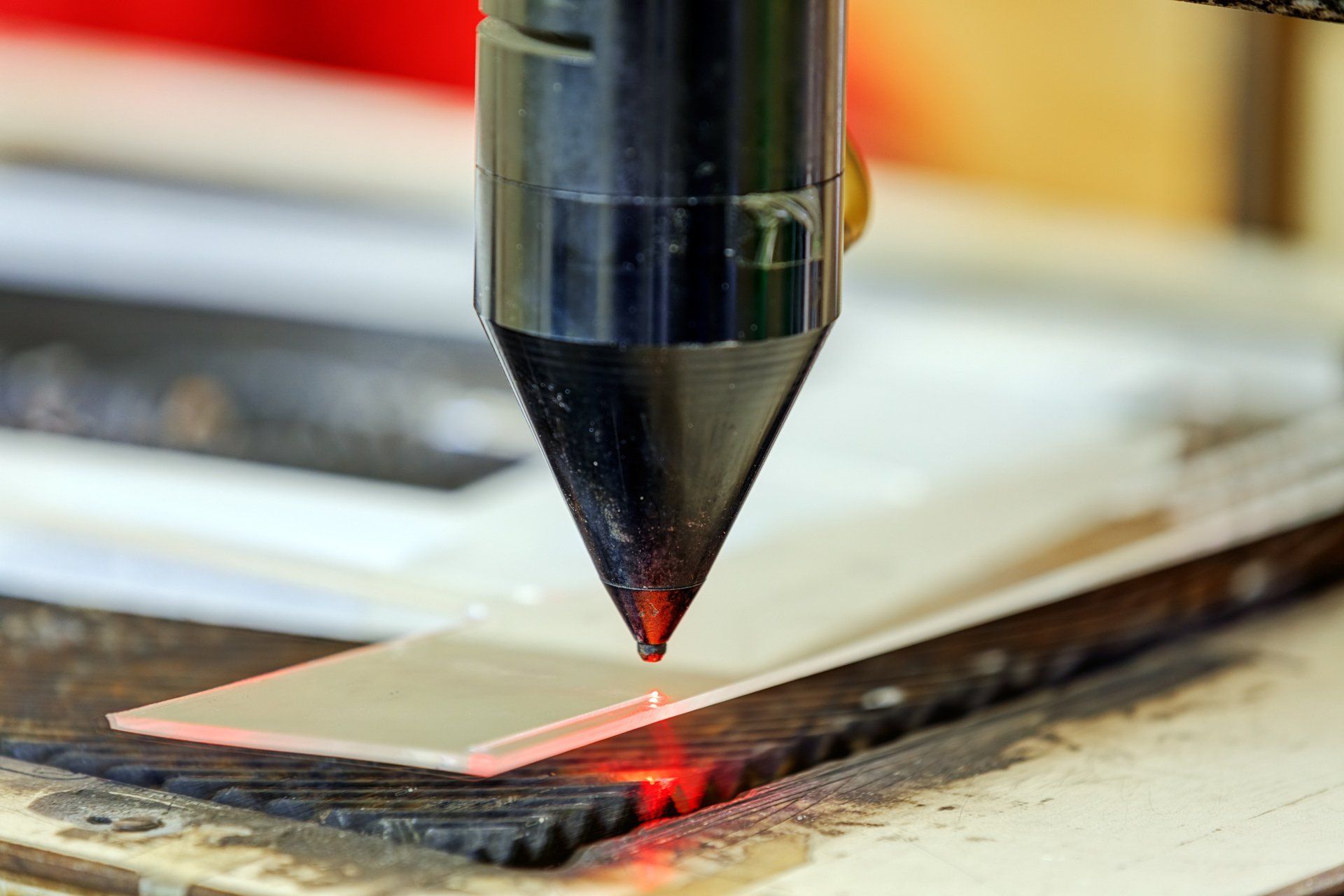

Material Extrusion

Material extrusion is an additive manufacturing (AM) process that uses a 3D printing technique to heat and deposit material. In this process, the material is pulled through a heated nozzle and deposited layer by layer. The nozzle can move horizontally, while the platform moves vertically, adjusting after each new layer is added.

While material extrusion may not offer the same level of speed and precision as other additive manufacturing processes, its affordability in terms of technology and materials has established it as the most popular method for 3D printing in home applications. In industrial settings, material extrusion finds use in rapid prototyping purposes.

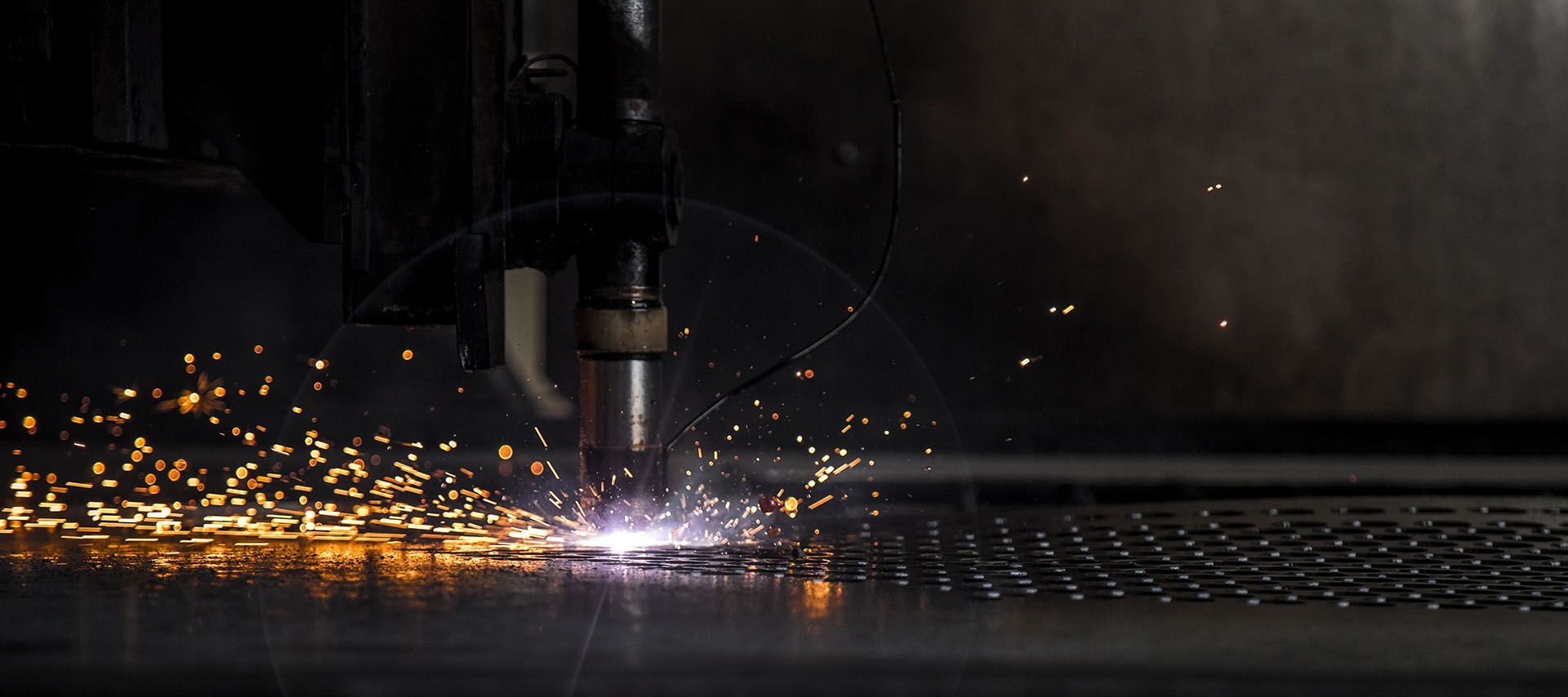

Powder Bed Fusion

Powder bed fusion is perfectly suited for manufacturing intricate 3D metallic parts, particularly those with complex geometry and intricate internal structures. It uses a variety of additive manufacturing techniques including direct metal laser melting (DMLM), direct metal laser sintering (DMLS), electron beam melting (EBM), selective laser sintering (SLS) and selective heat sintering (SHS).

In this process, the powdered material is fused layer by layer on a power bed using a laser or electron beam. Using selective laser sintering (SLS) technology, powder bed fusion (PBF) can print objects from a variety of materials such as plastic, ceramic, sand, wax, and metal. This process involves a laser beam that partially melts the particles, causing them to fuse together and form the desired object.

Sheet Lamination

Sheet lamination uses laminated object manufacturing (LOM) and ultrasonic additive manufacturing (UAM). Laminated object manufacturing is ideal for producing visually appealing items, utilising alternate layers of paper and adhesive. On the other hand, ultrasonic additive manufacturing uses ultrasonic welding to bond thin metal sheets together.

Vat Polymerisation

Vat polymerisation involves using liquid resin photopolymer to build an object layer by layer. In this process, ultraviolet light is directed by mirrors to cure the successive layers of resin through a process called photopolymerisation.

Wire Arc Additive Manufacturing

Wire arc additive manufacturing also known as directed energy deposition arc uses welding power sources to build 3D shapes. In this process, wire is used as the primary material source and follows a predetermined path to achieve the desired shape. Robotic welding equipment is typically utilised to carry out this method of additive manufacturing.

For more information, don't hesitate to get in touch with us for the

latest Sydney laser cutting services.

32 Harley Crescent Condell Park NSW, 2200 Australia

mail@hygradelaser.com.au

(02) 9791 1141

Find Us On: