32 Harley Crescent Condell Park NSW, 2200 Australia

What is Laser Cutting? A Quick Guide

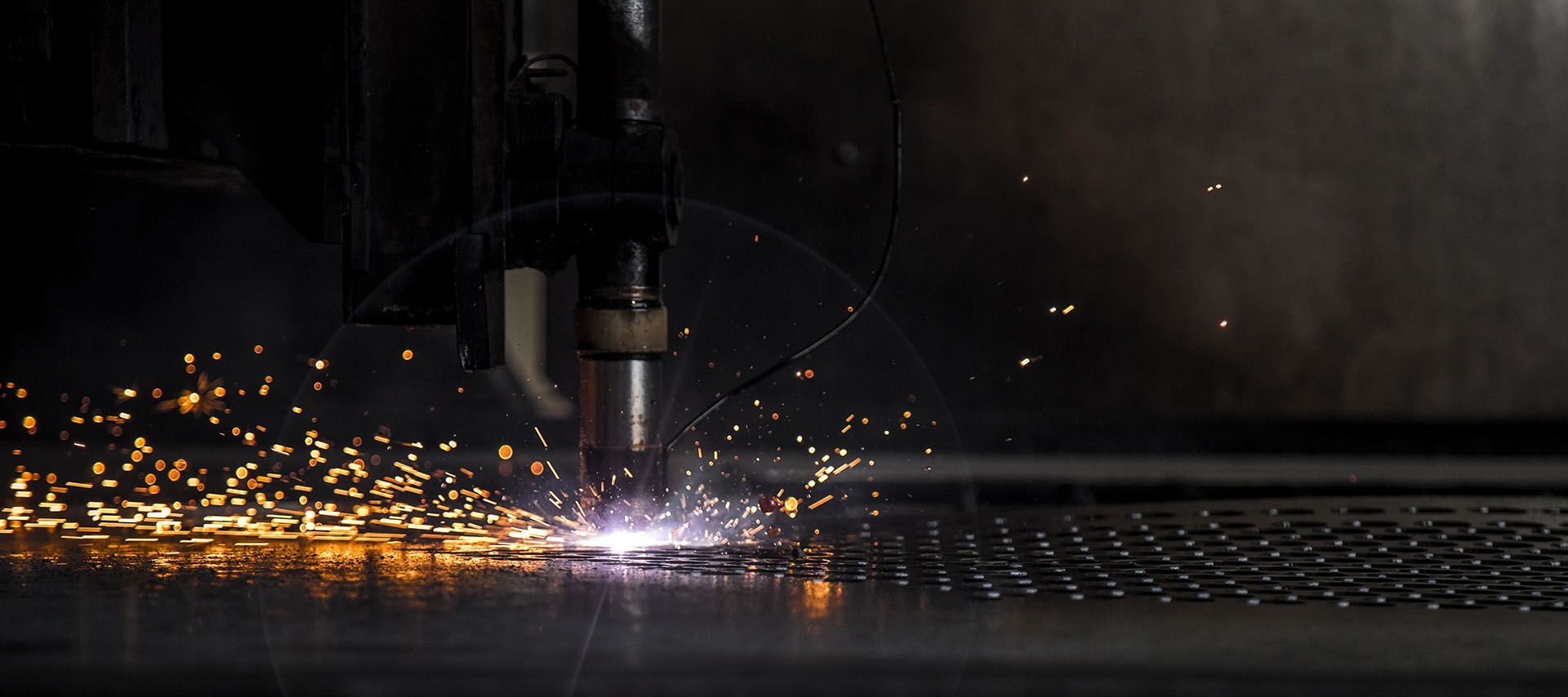

Laser cutting is a precise, computer-controlled process that uses a high-powered beam to melt, vaporise, or burn through materials. Unlike traditional cutting methods, this process allows for clean edges and intricate designs without physical contact, making it a preferred choice for manufacturing and fabrication.

How it Works

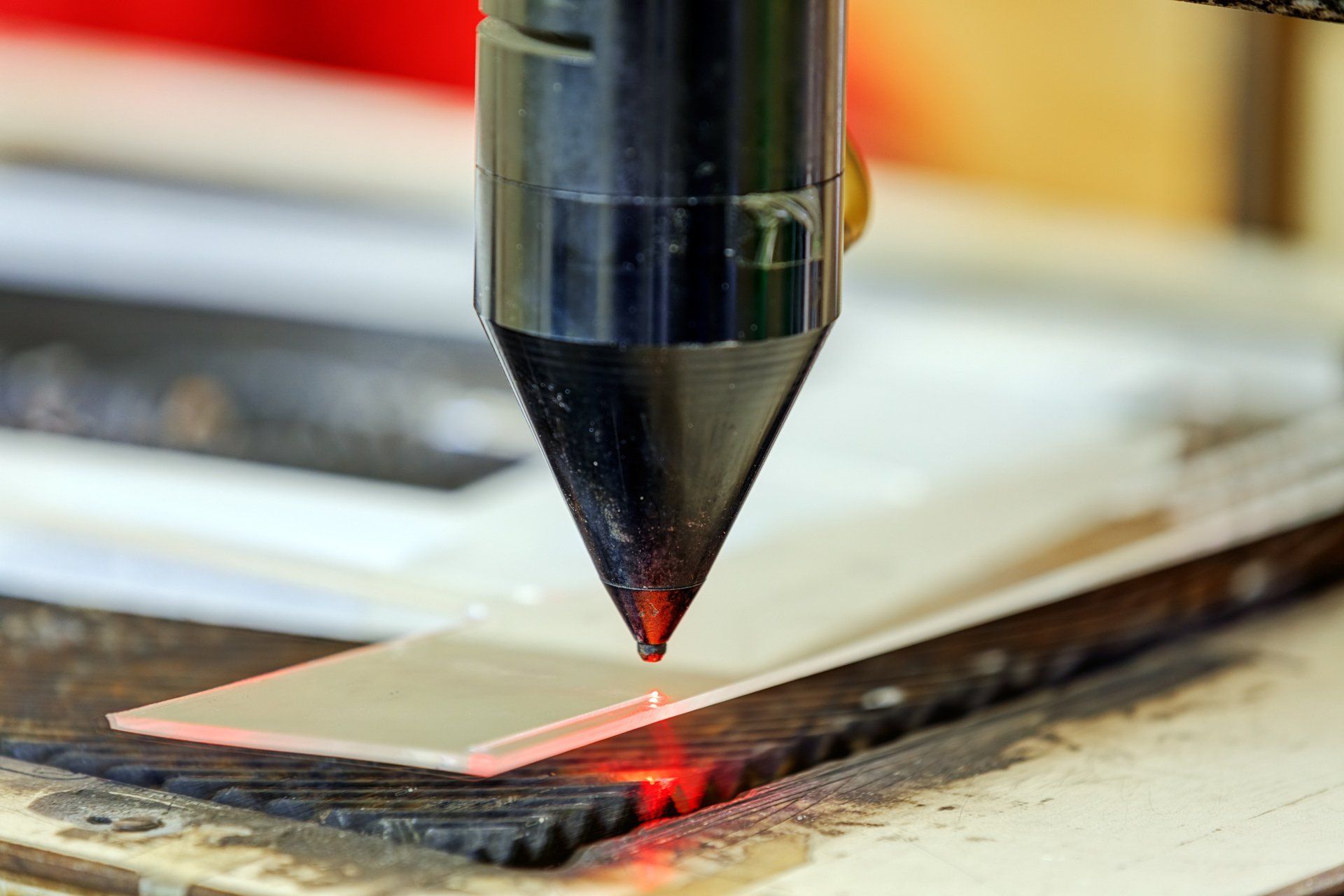

A focused laser beam is directed at the material, generating intense heat to create precise cuts. The beam’s power and intensity vary depending on the material being processed. This method is widely used for metals, glass, plastics, and other industrial materials.

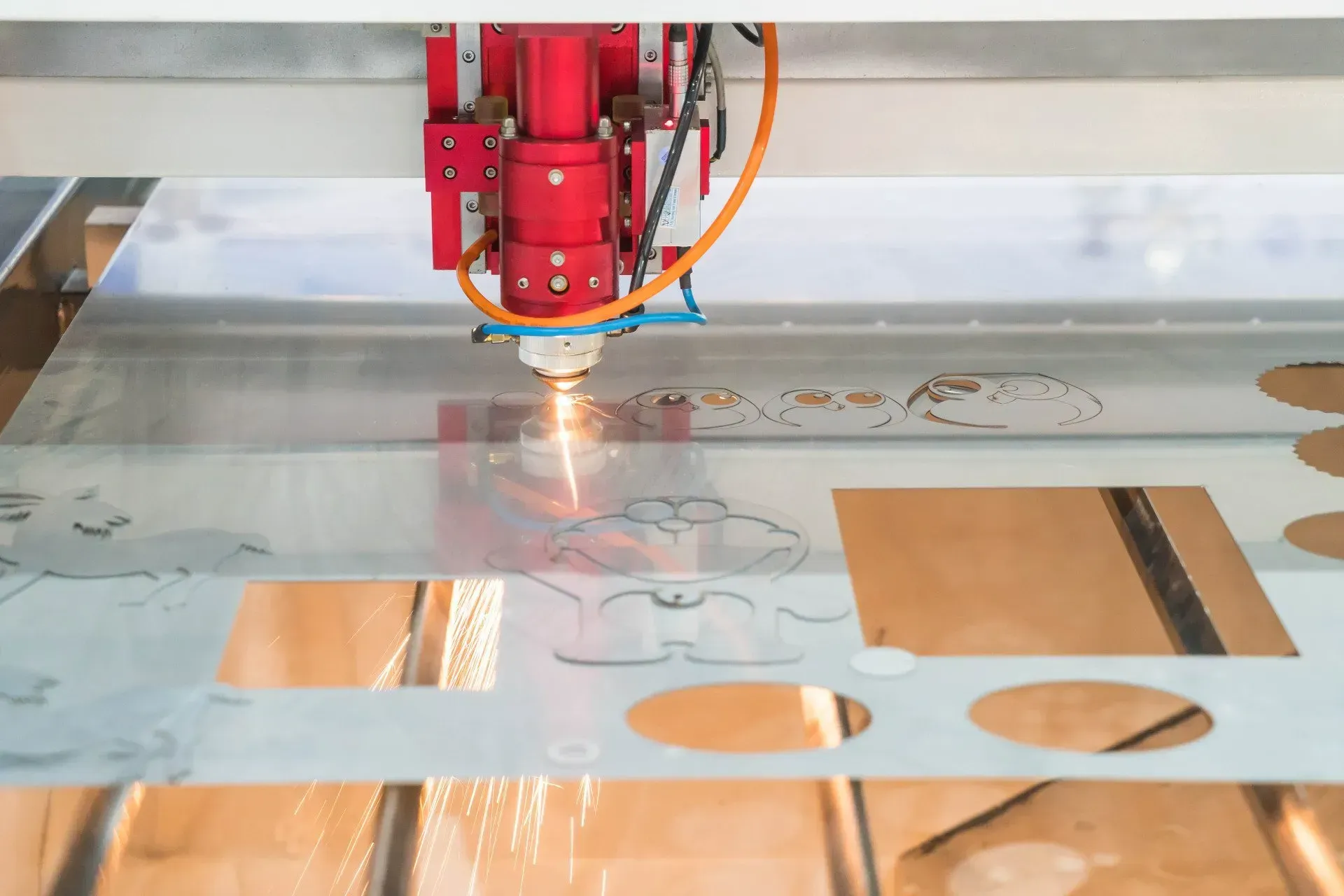

Cutting vs. Marking vs. Engraving

- Cutting: Fully removes material, leaving a clean separation.

- Marking: Alters the surface without removing material, often for serial numbers or barcodes.

- Engraving: Removes surface layers for decorative or functional designs.

Advantages

- High Precision: Delivers clean, accurate cuts with minimal waste.

- Versatility: Works on metals, plastics, wood, glass, and more.

- Speed & Efficiency: Faster than traditional cutting methods.

- Minimal Cleanup: Leaves smooth edges, reducing the need for post-processing.

Limitations

- Initial Cost: Machines can be expensive for small businesses.

- Operator Skill: Requires trained personnel for quality results.

- Fume Production:

Proper ventilation is essential for safety.

Applications

Laser cutting is used across various industries, including:

- Manufacturing: Cutting precision metal parts.

- Construction & Architecture: Creating decorative panels and signage.

- Automotive & Aerospace: Producing lightweight, durable components.

- Creative & Artistic Projects:

Engraving and marking for custom designs.

Why Choose Hygrade?

With over 30 years of experience, Hygrade Laser Profiling delivers precision, efficiency, and high-quality results. Our expertise allows us to cut intricate shapes and create decorative metalwork, offering solutions tailored to industries and custom projects.

Talk to an Expert

If you need high-quality metal cutting for industrial or artistic applications, Hygrade Laser Profiling is here to help.

Contact us today to discuss your project.