32 Harley Crescent Condell Park NSW, 2200 Australia

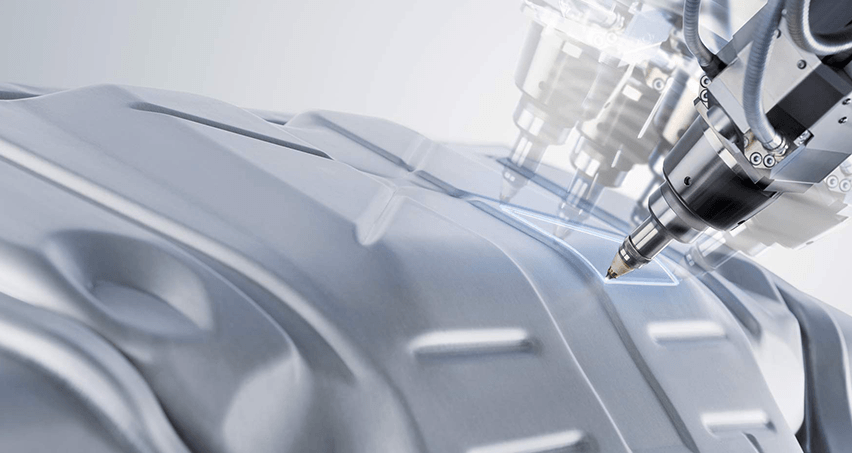

Unique Qualities of Laser Beams and How The Laser Cutting Process Works

What makes laser light unique?

Why is a laser beam ideal for production?

What happens when cutting and drilling with a laser?

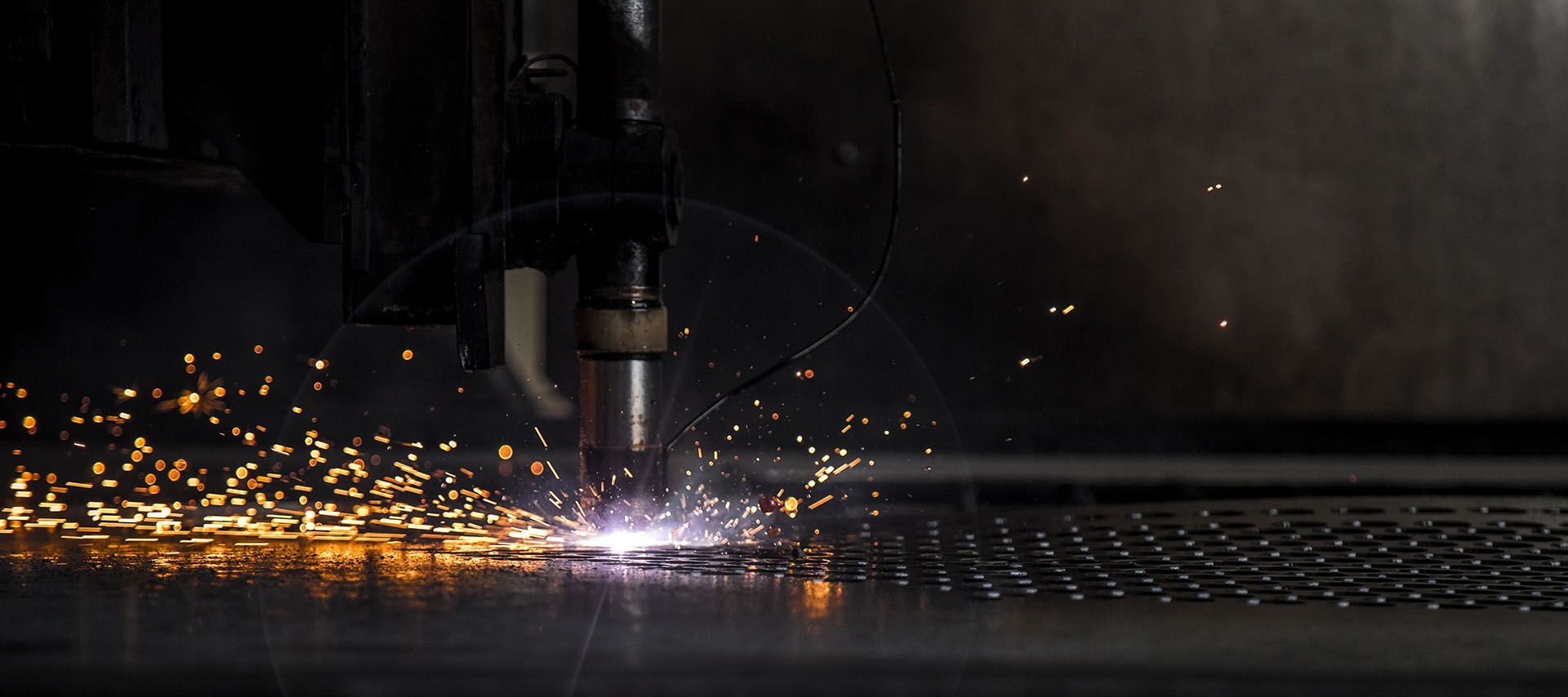

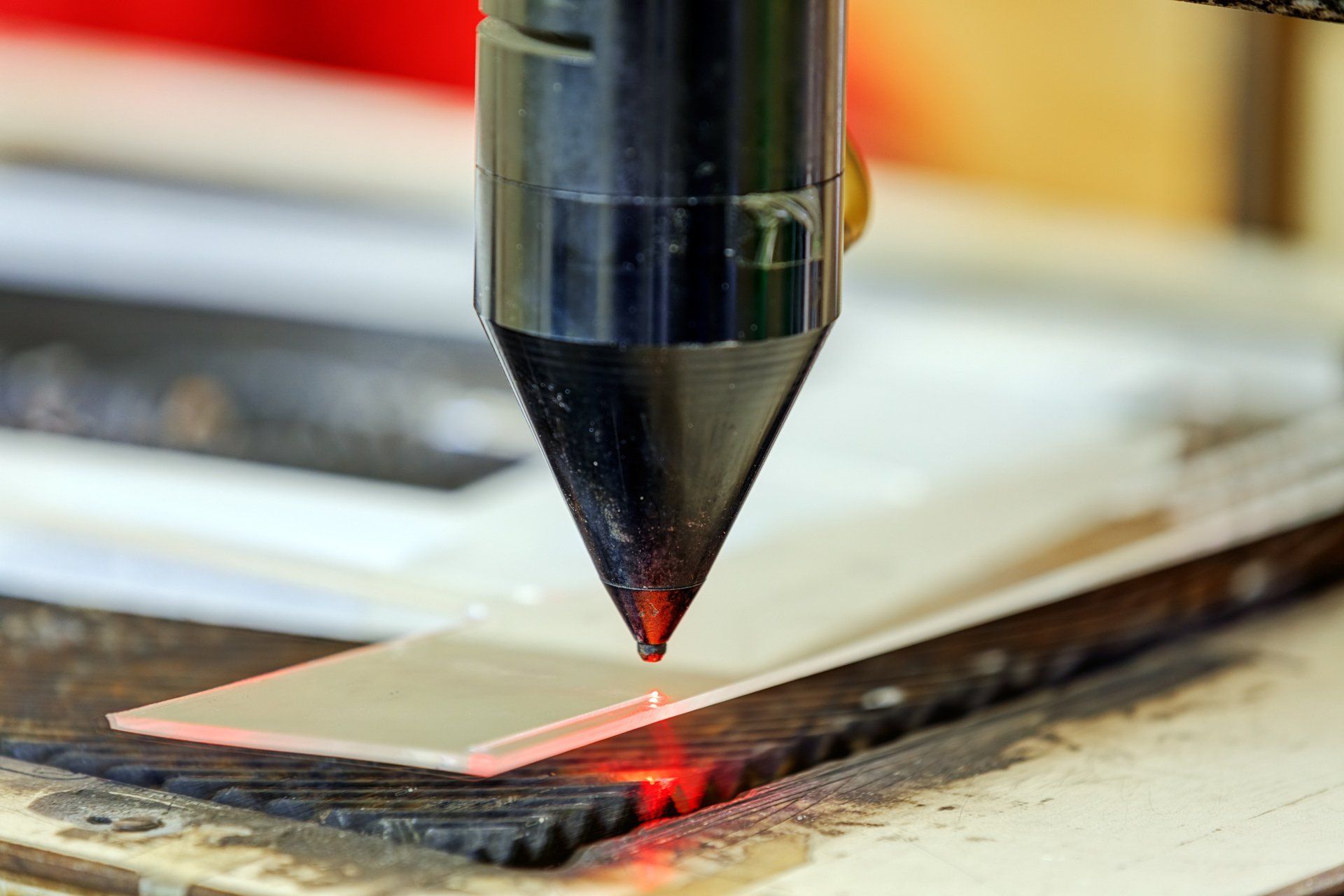

When a focused laser beam hits the workpiece, it heats up the material causing it to either melt or evaporate. The cutting process can start once the beam has fully penetrated the workpiece. The laser beam moves along the part contour, melting the material.

Generally, a gas flow blows the melt down and out of the kerf, which is not much wider than the focused laser beam itself. While the laser drills, a short laser pulse with high irradiance melts and evaporates the material. A high pressure is in turn generated, and the melt is forced out of the hole.

Read more about our professional laser cutting solutions or get in touch to find out how we can help you with a project.