32 Harley Crescent Condell Park NSW, 2200 Australia

The Differences Between Co2 Lasers and Fiber Lasers

Buying the right machine for your business can be tough. It’s not like buying a car where you decide on the look, colour or model – buying a machine requires a lot more thought.

It’s always best to evaluate the pros and cons of the machine and assess how it will benefit your business.

For Michael White, deciding on a Co2 Laser or a Fiber laser is a challenging decision to make. Both machines have the speed and accuracy to do the job and both produce quality products.

The differences between Co2 Lasers and Fiber Lasers are:

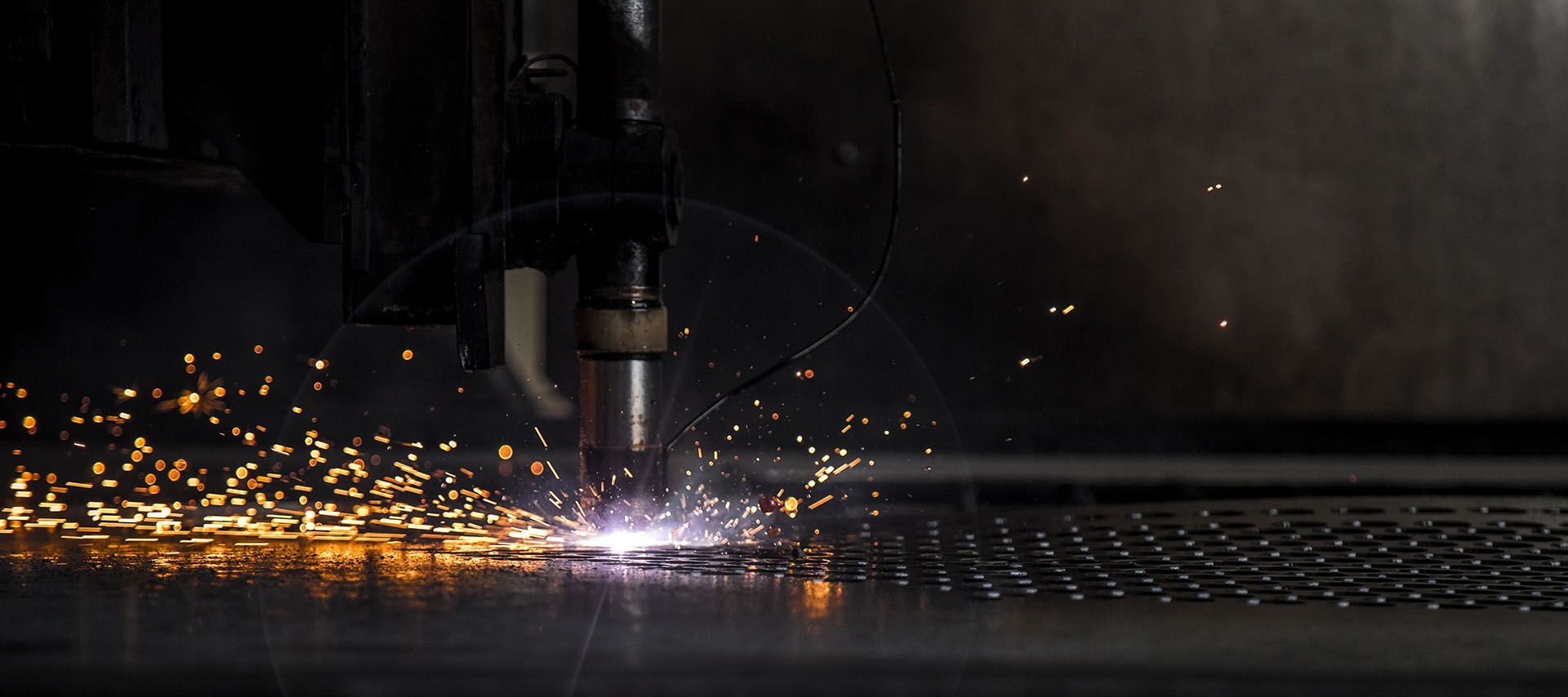

Co2 Laser

- Speed – Faster than Fibre lasers in materials thicker than 5mm as the laser can be absorbed better at higher levels of incidence.

- Quality – Quality is consistent throughout all thicknesses of material

- Flexibility – high, suitable for all material thicknesses

- Costs per part – reduces for materials over 5mm in thickness.

- Safety – CO2 laser light (10µm) is absorbed by the cornea, there is no risk of irreparable damage to the retina.

- Beam guidance – flying optics via mirrors

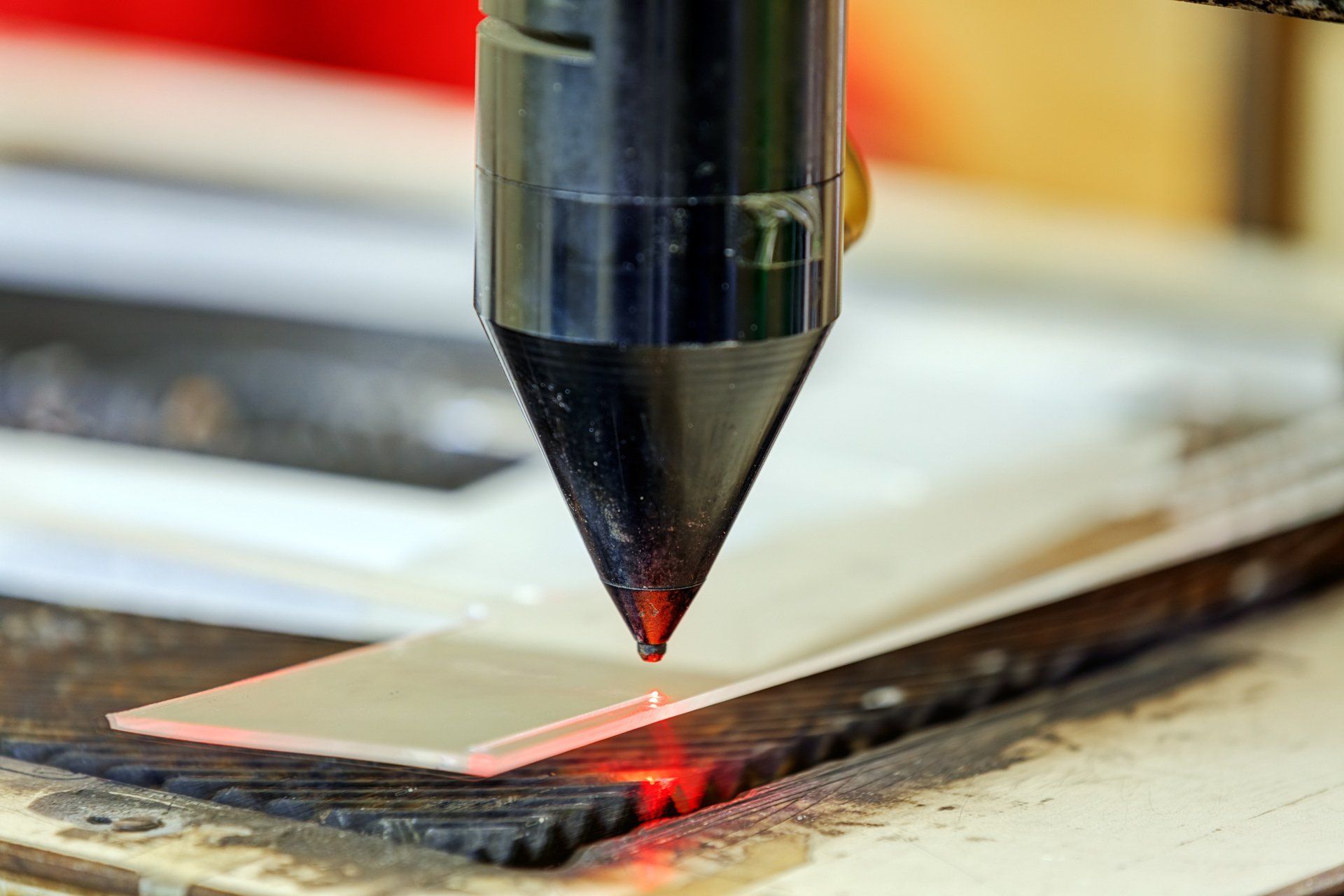

Fiber Laser

- Speed – Faster than CO2 lasers in thin materials as the laser can be absorbed quickly slight lead in speed when cutting with Nitrogen (fusion cutting)

- Quality – comparable up to 5mm

- Flexibility – much improved with the introduction of BrightLine Fiber and CoolLine

- Cost per part – less than the CO2 laser, mainly due to lower running costs and reduced power consumption, no laser gases required and no lense replacement

Safety – Strict safety precautions must be taken as the laser can pass straight through to the eye’s retina.

Beam guidance – fibre optics leading to less maintenance and repair costs

Researching the right machine for your business will help you increase business efficiency and in the long run save you money.

RECENT POSTS