32 Harley Crescent Condell Park NSW, 2200 Australia

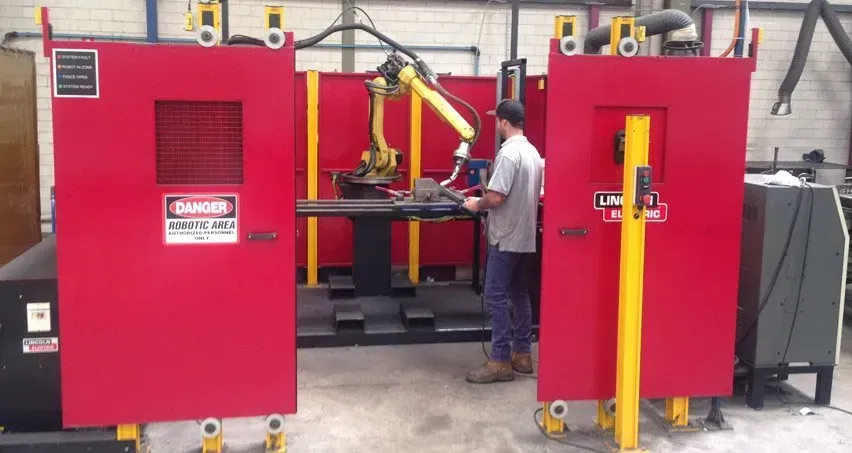

Efficient Welding Using the Lincoln Robotic Welding Cell

Robotic welding is a fast and consistent process for welding sheet metal. The robotic cells deliver a better product to customers with improvements to the output quality, and delivery times. Specialising in Arc and Spot welding, Hygrade Laser Profiling’s new Lincoln Robotic Cell is creating exceptional results for their customers.

Michael from Hygrade Laser Profiling, says, robotic welding is becoming more popular over conventional welding because of its speed.

“Robotic welding is allowing us to complete jobs faster because of its ability to move from one weld to the next quickly and efficiently,

“It certainly speeds up the process allowing us to tackle a number of jobs at the one time,” Michael says.

Robotic welding has a number of advantages that include:

– Consistent cycle times

– No break in production

– Better weld quality

– Increases efficiencies and consistencies

The Lincoln robotic welding cell used by Hygrade Laser Profiling is the perfect tool to use when creating parts for industries like automotive, architecture, construction and transport.

Robotic welding has certainly made a difference to Hygrade Laser Profiling and Michael says it has impressed his customers.

“Nowadays, we are constantly looking for equipment that gives us the ability to perform tasks efficiently and significantly faster than manual welding… and thankfully the Lincoln Robotic cell does that,

“Being able to complete tasks at a high standard is essential in any business and it means that our customers will continue to use Hygrade for all their fabrication needs,” Michael says.

For more information contact Hygrade Laser Profiling.

RECENT POSTS