32 Harley Crescent Condell Park NSW, 2200 Australia

Comparing Energy Consumption: Fiber Lasers vs CO2 Lasers

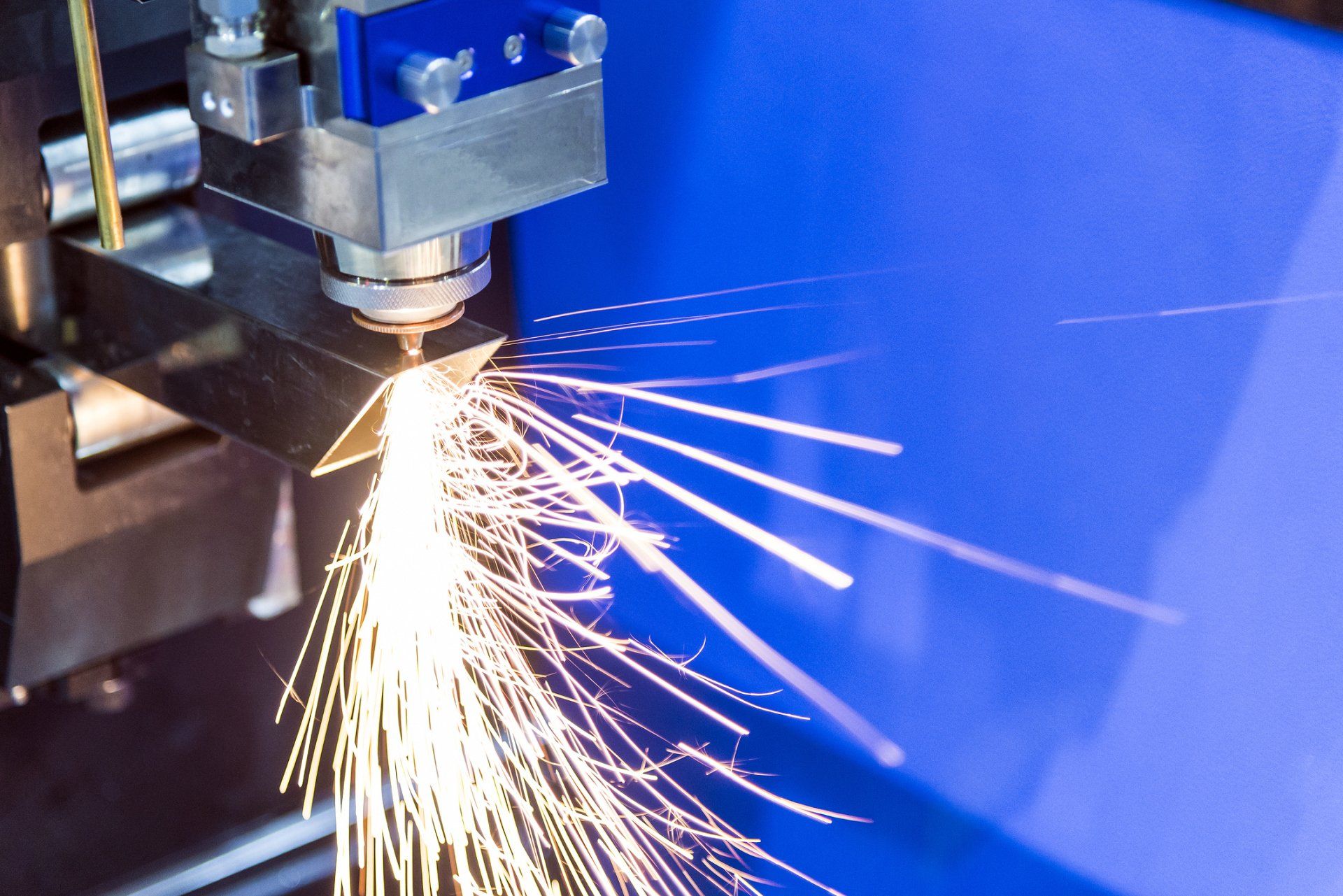

When it comes to sheet metal cutting, professionals have the option to choose between fiber laser cutters and CO2 laser cutters. However, despite sharing the common purpose of cutting sheet metal, notable distinctions between these two laser machines are evident. Significantly, there have been rapid advances in fiber laser technology used for laser cutting.

Comparing energy consumption between fiber laser cutting and CO2 laser is an important aspect for Sydney laser cutting services. In recent years, these two technologies have rapidly advanced in becoming more efficient by reducing their energy consumption levels while still providing high-quality cuts.

Considering these advancements, it becomes essential to take certain factors into account when choosing a laser-cutting machine. One major thing to consider is sustainable manufacturing, which looks at the energy consumption of fiber laser and CO2 laser. Through this article, we can better understand the differences between these two technologies and take a look at the important factors that determine which option is more energy-efficient.

What are fiber lasers and what are they good for?

Fiber lasers use optical fibers as their active medium. When a silicate or phosphate glass fiber absorbs the initial light from pump laser diodes and converts it into a laser beam with a diverse array of wavelengths. The beam path delivery system then guides the laser beam from the source to the target material.

The focus of the fiber laser system basically lies in the utilisation of fiber optics as a delivery mechanism to concentrate light into a single point. With a fiber laser, the fiber optic receives the light and amplifies it, directing it towards the laser pointer.

Through the integrated delivery system, fiber lasers eliminate the need for mirrors or lenses that are typically used in traditional laser systems. Not only does it increase the efficiency of the laser by reducing energy loss, but it also reduces the risk of alignment issues that can affect the accuracy of the laser operation. Thus, the beam path delivery system plays a significant role in the performance and reliability of fiber lasers.

Due to this, fiber lasers are often used in several applications including fiber laser cutting, engraving, marking, drilling, and welding. The versatility of fiber lasers allows them to be employed across various sectors, including medicine, defence, telecommunications, automotive, spectroscopy, electrical engineering, manufacturing, and transportation.

What are CO2 lasers and what are they good for?

A CO2 laser is capable of marking, engraving, and cutting metal like stainless steel as well as a wide range of non-metallic materials such as wood, plastic, glass, and acrylic. Basically, CO2 lasers use a resonator, together with purging gases and high-speed blowers to generate potent light particles. These particles collide with each other, resulting in the production of high-intensity light that can effectively cut through thicker materials.

Unlike fiber lasers that are sensitive to back reflections, CO2 lasers use a beam path delivery system that works differently by relying on reflection and refocusing instead of focal lenses, making them much more reliable in cases where there is a high risk of damaging the laser source due to back reflections.

CO2 lasers are very popular for industrial applications such as the production of signs and machinery parts. Moreover, CO2 lasers can also be used in non-industrial settings such as medical care, mobile communication devices, integrated circuits, laser therapy, and prototyping.

For cutting thicker materials, CO2 lasers are the recommended option. CO2 lasers offer faster initial piercing times, swifter straight-line cutting, and a smoother surface finish when cutting materials that are over 5 mm in thickness.

Factors To Consider When Choosing Between Fiber Lasers and CO2 Lasers

Image by wirestock on Freepik

A growing interest in the industry today is sustainable manufacturing and how we as a whole can be more energy efficient in the manufacturing space and increase the awareness of sustainable production.

Laser cutting can have a considerable amount of impact on the environment, so when deciding which laser to purchase, it's important to consider the following factors:

Wavelength

A fiber laser generates light approximately at 1064 nm (or 1.064 µm), whereas a CO2 laser produces light at 10.6 µm (or 9.6 µm for some types). Thus, fiber lasers produce shorter wavelengths than CO2 lasers.

Sustainability

There are no laser gases required with a fiber laser, which ensures reduced power consumption and a sustainable impact level. The fiber laser is a solid-state system that doesn't require a specialised laser gas. In general, traditional CO2 lasers require much more maintenance.

Cutting Speed

A high-powered fiber laser has a cutting speed that is five times faster than that of a CO2 laser. With a power consumption that is 30% lower, fiber lasers enable faster and more resource-efficient completion of tasks. As an example, a 2kW fiber can cut thin materials as fast as a 4-5kW CO2.

Energy-Efficiency

Fiber lasers exhibit remarkable energy efficiency, which is higher than CO2 laser equivalents. For instance, a high-power CO2 laser operating at maximum power will typically consume around 70kW of electricity, while a fiber laser with a similar power rating only consumes approximately 18 kW.

Energy Source

Fiber lasers utilize LEDs to emit light that is subsequently concentrated by fiber optic lenses that amplify the light to achieve desired outcomes. On the other hand, CO2 lasers stimulate a combination of gases such as CO2, N2, and Xe to generate intensified waves for easy cutting of various objects.

Operating Costs

While both machines have the speed and accuracy to produce high-quality products, a fiber laser is considered more cost-effective and energy efficient as it costs less per part than the CO2 laser, due to lower running costs. Hence, a CO2 laser uses more power during operation, which results in higher operating costs.

Maintenance

Basically, fiber lasers eliminate the need for maintenance tasks such as lens cleaning or aligning the beam paths. In contrast, a CO2 laser may require an additional 4 to 5 hours per week for these activities.

Quality

A fiber laser machine is capable of cutting metals like copper, brass, and aluminum workpieces with more safety and precision than a CO2 laser machine. This is because these materials absorb the beam from the fiber more efficiently, reducing the likelihood of reflection. On top of that, a fiber laser generates steadier beams that are typically narrower and more precise than a CO2 laser, which means that fiber laser cuts are higher in quality compared to CO2 laser cuts.

Takeaway

When it comes to laser cutting, you can rely on a fiber laser or a CO2 laser to make precision cuts for you. Depending on the material, specifications, and requirements, one may be better suited than the other.

For cutting thin materials, fiber laser technology is the better choice as it offers higher levels of accuracy, safety, and quality compared to a CO2 laser machine. For applications that require finer details or more complex designs, fiber laser machines are usually the go-to option.

In contrast, CO2 lasers are better at cutting through a wide range of materials including non-metals and thicker materials. Due to their higher power, faster initial piercing times, precise cutting, and enhanced surface finishes, CO2 lasers are usually the preferred option for the majority of large-format laser cutting applications.

However, when it comes to energy consumption, fiber laser cutting is undeniably more efficient because it consumes less power to produce the same amount of energy as a CO2 laser. While CO2 lasers can produce good cutting results, the amount of electricity required to run them is significantly higher than with a fiber laser. What's more, fiber lasers also require less maintenance, which could potentially minimise downtime and operational costs.

For more information on our laser cutting services, please don't hesitate to get in touch.