32 Harley Crescent Condell Park NSW, 2200 Australia

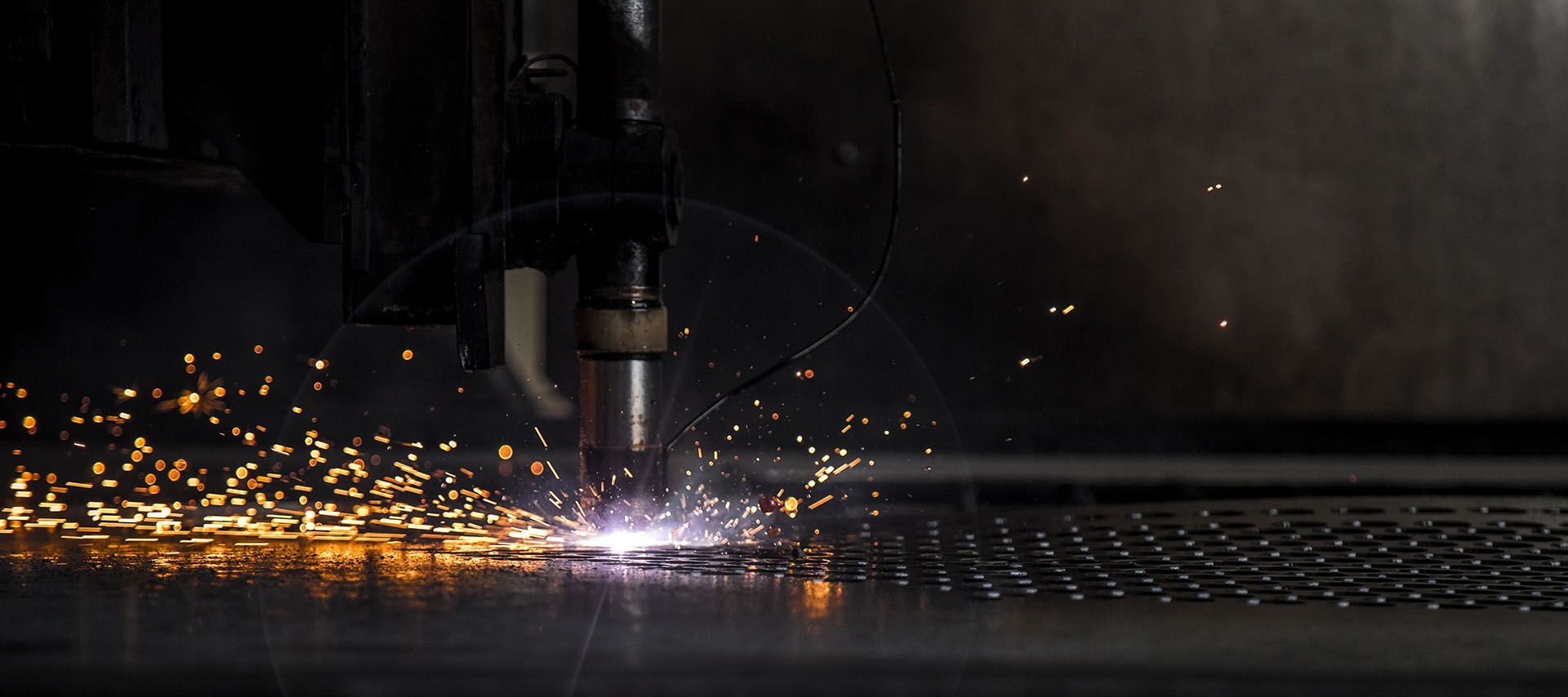

Can a 40 Watt Laser Cut Metal?

Whether you need metal cutting or metal engraving services, finding the right Sydney laser cutting company is essential to ensure accurate and efficient results. However, before diving into your search, it can be beneficial to familiarise yourself with the capabilities of different laser cutting machines. Knowing about these will help you in making an informed decision and finding the company that can meet your specific requirements effectively.

So, can a 40 watt laser cut metal? In this article, we'll find out the answer and explore what laser cutting machines are capable of.

Image by wirestock on Freepik

What will a 40 watt laser cut?

Laser cutters are designed to cut, engrave, and mark a variety of materials including metals. Since a laser cutter has the ability to cut smoothly, it can be used ideally to cut metals such as aluminium, brass, tungsten, nickel, and steel. However, given that metal surfaces are strong and resistant, most laser cutters require more power than a 40W laser cutter.

In general, cutting metal requires a much higher-power laser such as a fibre laser or a high-power CO2 laser with a power output of at least 500W or more, depending on the type and thickness of the metal being cut.

And since a 40W laser is not powerful enough to cut through metals, it can be only used for engraving or marking coated metals, anodised aluminium, or painted surfaces. Significantly, it can mark the metal surface without actually cutting through the metal itself.

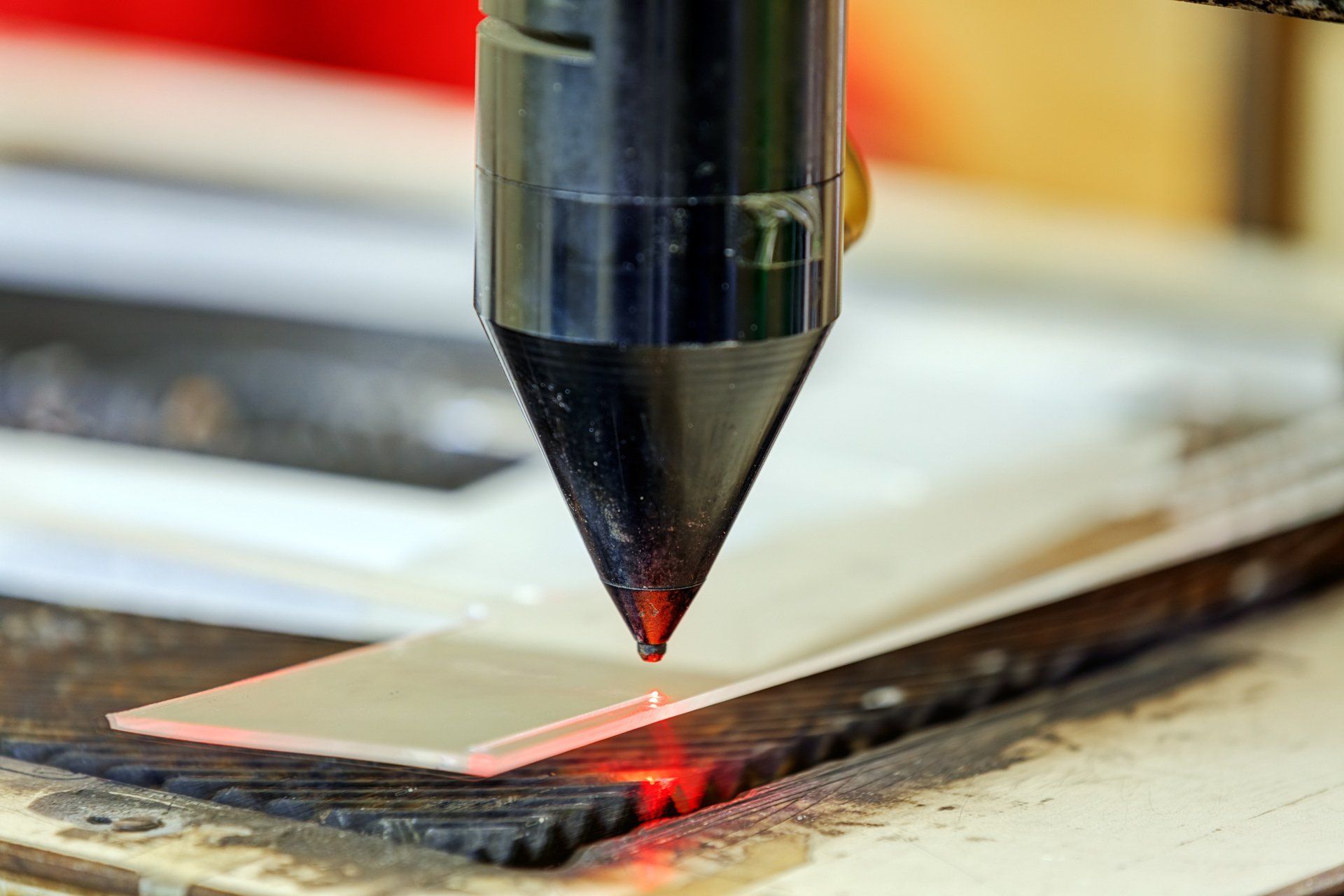

Can a 40W laser engrave metal?

Laser engraving is a process that uses a highly focused laser beam to create precise, detailed markings on a metal surface. As part of the process, a laser tube is used to generate the intense light needed for marking and engraving. Composed of a highly reflective chamber filled with gas, the laser tube produces a beam of coherent light, which is targeted onto the surface to be marked.

For direct laser metal engraving, fibre laser is a great choice as it is specifically designed for applications involving high precision and versatility. Since it is more effective to use in metal marking, its high power makes it ideal to use in laser engraving applications. Generally, a 40W laser cutter should be able to mark and engrave metal surfaces directly with high efficiency.

Significantly, if you want to improve the performance and functionality of your laser engraver, you can use an upgraded control board. Not only does it increase the accuracy of your engraving results, but it also increases the speed and precision with which the laser can move.

What wattage laser will cut metal?

When it comes to cutting metals, it is important to note that different types of materials require different laser types and laser wattages. For metal surfaces, CO2 lasers and Fiber lasers are the most common types of lasers to use.

CO2 Lasers

In modern CO2 machines, the laser beam is typically generated within a sealed glass tube filled with gas. When a high voltage passes through the tube, it energises the gas particles and produces light.

To effectively cut metal using a CO2 laser, it is necessary to have a minimum power supply of 150W. Additionally, for safety reasons, it is crucial to have an air assist feature in place. This helps mitigate the risk of sparks and other potential hazards during the cutting process.

Through an oxygen assist or an air assist, you can be able to minimise heat around the laser head, remove molten metal and gasses from around the contact point, and ultimately ensure safety within your workplace. On top of that, air assist also allows you to achieve better engraving and laser-cutting results.

In general, high-powered CO2 lasers are designed to cut metal types such as steel and stainless steel. However, in metals such as aluminium and brass, which have high reflective properties, C02 laser cutters might not work well due to laser beam rejection.

Fibre Lasers

On the other hand, if you are looking for more precision, fibre laser machine is the perfect option. Fibre lasers excel in cutting metals at a faster pace and with greater precision due to their smaller laser beam size. Not only are they easier to use but they are also more cost-effective in terms of electricity usage and long-term maintenance.

In order to cut metal effectively, you may need to use an industrial fibre laser of at least 2,000W particularly if your goal is to cut thick metal precisely. Keep in mind that you cannot laser cut thick metals with a power supply of 20W to 50W as it won't be able to generate enough heat.

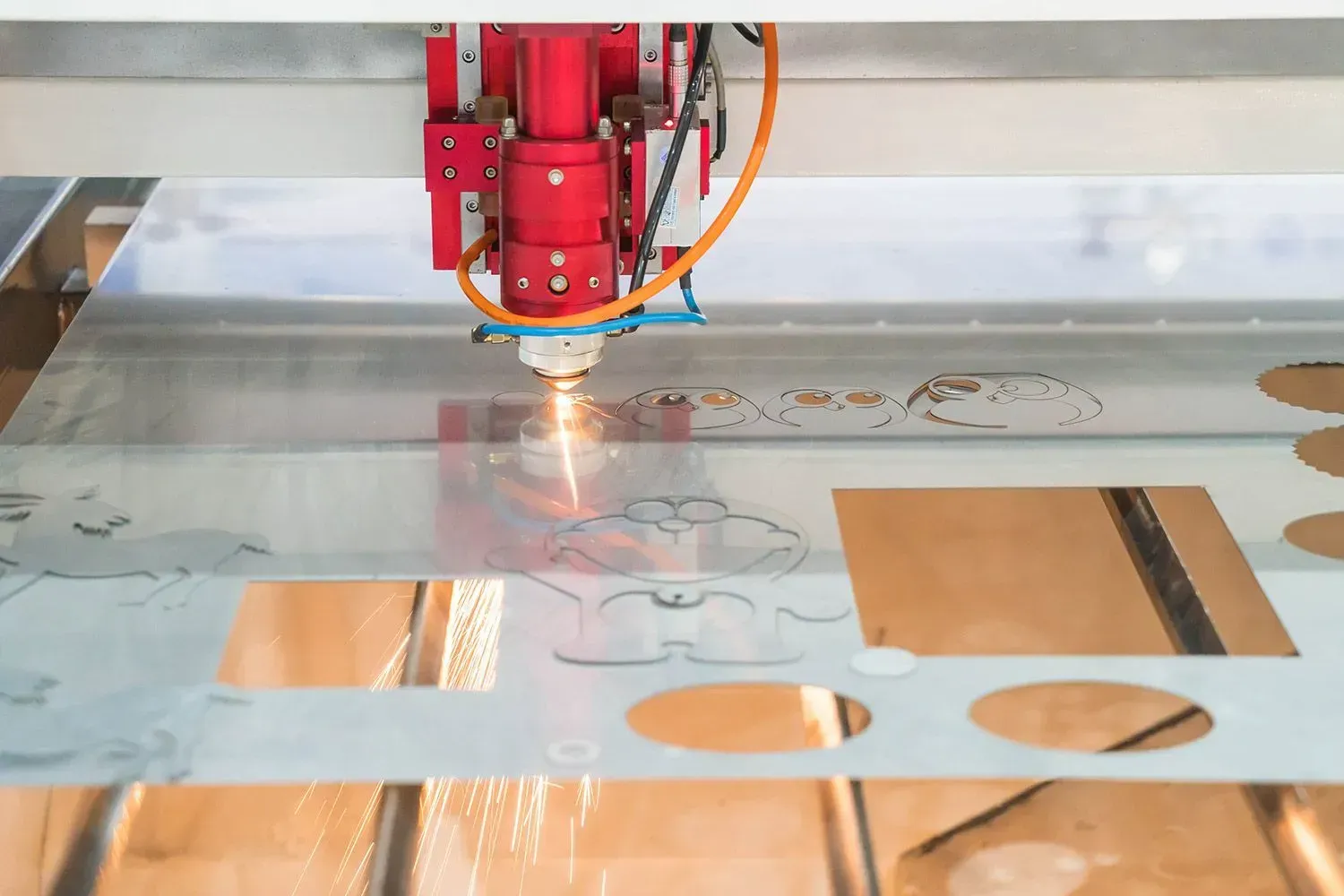

Can 40W CO2 laser cut metal?

Image by wirestock on Freepik

When it comes to metals, we all recognise their exceptional durability. Since metals are composed of hard alloys and other strong elements, even the most advanced cutting tools may not be able to cut them easily. That is why laser cutters are essential to quickly and accurately cut through tough metals.

However, it's important to note that not all laser cutters possess the required power to accomplish this task. While a 40W power supply is generally sufficient for cutting non-metallic materials like acrylic, wood, and paper, a 40W CO2 laser cutter lacks the required power to make deep and precise cuts in metal. To achieve effective metal cutting, a laser cutter must have a minimum power supply of 150W, supplemented by air assist to ensure the laser beam is powerful enough to through it.

In order to find the best laser machine for metal cutting, look for features such as high power output, speed and accuracy. Additionally, you should also consider the size of the metal that you are going to cut. When working with thicker metals, you may need a more powerful laser cutter.

How powerful is a 40W laser?

A 40W CO2 laser is considered a moderately powerful laser cutter and laser engraver. With its low to medium power supply, it can cut, engrave, and mark various materials ranging from wood, acrylic, fabric, paper, leather, and a few types of plastic. With a 40W laser cutter, you can typically cut up to 5mm of acrylic and 6mm of softwood. For intricate designs, lower the cutting speed yields to achieve better edge quality and precision. By reducing the speed sufficiently, it becomes possible to achieve a smooth and polished edge.

However, as much as it works flexibly in several types of materials, a 40W laser cutter might not be suitable for heavy-duty industrial applications or even for cutting thicker materials such as metal. In such cases, it is advisable to opt for lasers with a greater power supply.

How much power does a laser need to cut steel?

Compared with other types of metals, steel is highly strong and durable due to its composition and properties. Even when exposed to high temperatures, it retains its shape and does not deform easily. Not only that, but steel is also resistant to corrosion. For these reasons, a higher wattage of laser power is needed to cut it completely and effectively.

Depending on the thickness of the steel, the desired cutting speed, and the type of laser cutter to be used, most high-powered CO2 lasers can cut thick metals such as steel.

In general, laser cutters with lower wattage are well-suited for cutting thinner materials like paper or plastic. Conversely, higher wattage laser machines are more suitable for thicker materials, such as metals, ensuring effective cutting capabilities.

Takeaway

Laser cutting process is an incredibly precise and effective way to cut through the toughest of metals. Aside from choosing the right type of laser cutter, it is always important to set the correct wattage as well as the best cutting speed for the metal being cut. With these factors in place, you can guarantee a consistent and accurate cut for all your projects.

In this blog, we learned that a 40-watt laser cutter is good for marking and engraving. But when it comes to metal cutting applications, you need more powerful laser cutters. At Hygrade Laser Profiling, we use laser cutters that are way more powerful than most laser cutters in the market.

Designed with advanced technology, our laser cutters can easily cut through various metals including aluminium, brass, copper, stainless steel, and mild steel, with absolute accuracy and precision. Furthermore, our top-notch lasers can cut up to 25mm of mild steel, 20mm stainless steel, and 15mm aluminium.

So if you're looking for custom metal laser cutting services, get in touch with us today so we can help you find the perfect laser cutting solution for your project.

32 Harley Crescent Condell Park NSW, 2200 Australia

mail@hygradelaser.com.au

(02) 9791 1141

Find Us On: