32 Harley Crescent Condell Park NSW, 2200 Australia

HYGRADE LASER PROFILING

MILD Steel Laser Cutting

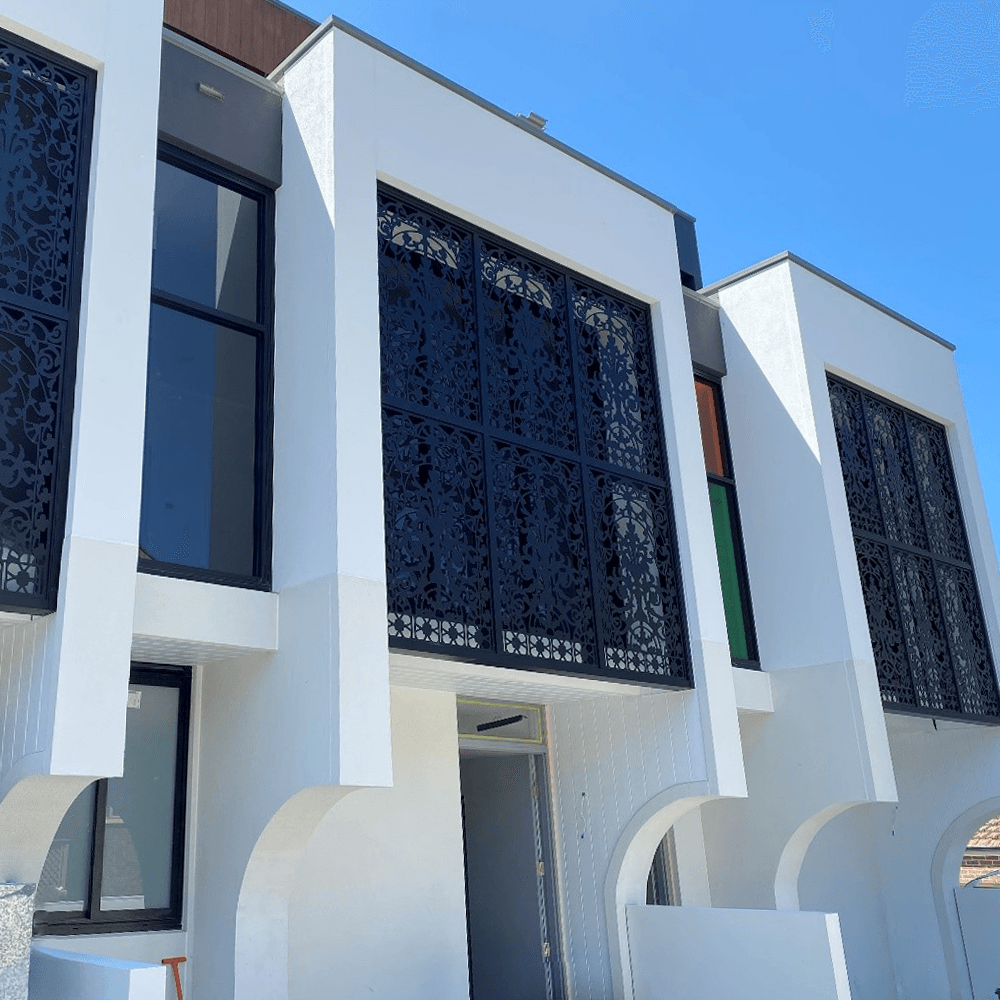

For over 30 years, Hygrade Laser Profiling has delivered high-precision mild steel laser cutting efficiently and accurately. Our advanced technology ensures clean, precise cuts and high-quality results for projects of all sizes. You can also view our full range of

laser cutting in Sydney through our home page.

Technology We Use

At Hygrade Laser Profiling, we use advanced TRUMPF L3050 5kW machines and the TRUMPF TruLaser Tube 3000 Fiber to deliver high-precision mild steel laser cutting.

Trumpf TruLaser Tube 3000

TRUMPF TruLaser Tube 3000 Cutting Capabilities

| Material | Maximum Cutting Thickness |

|---|---|

| Mild Steel | 8mm / 8mm |

| Stainless Steel | 6mm / 4mm |

| Aluminium | 6mm / 4mm |

| Brass | 3mm / 4mm |

| Copper | 3mm / 4mm |

MATERIAL RANGE

STANDARD

Rectangular Profile

RHS Min

152mm x 15mm

Parallel Flange Channels

PFC Max

150mm x 75mm (Max Weight 20 KGs per Metre)

Flatbar

Flatbar Max

160mm Wide

Unequal Angle

UA Max

125mm x 100mm

We also laser cut EA (Equal Angle)

TRUMPF L3050 5Kw Features

- Cutting of up to 20mm stainless steel.

- Cutting of up to 25mm mild steel.

- Cutting of up to 15mm aluminum.

- Tube processing (rotolas).

- 1500mm x 3000mm cutting area.

- The TRUMPF L3050 is an industry-defining laser metal cutting machine which is why we chose two for our shop.

WHAT CLIENTS SAY ABOUT OUR MILD STEEL LASER CUTTING SERVICES

HYGRADE CAN MANUFACTURE YOUR NEXT PROJECT.

Mild Steel Laser Cutting FAQs

What is mild steel laser cutting?

Mild steel laser cutting uses a focused laser beam to cut mild steel with high accuracy. It gives smooth edges, steady results and clean shapes with very little waste.

How thick can you cut mild steel?

We cut mild steel up to 25mm with our TRUMPF L3050 5kW machines. This gives strong, reliable cuts for both small and large jobs. Our mild steel laser cutting setup handles most project needs.

Why choose mild steel laser cutting over other methods?

Mild steel laser cutting is faster, cleaner and more accurate than plasma or mechanical cutting. It creates less heat on the metal, so the part keeps its shape. The finish is smoother and needs less clean-up.

Can you cut different shapes and profiles?

Yes. We cut flat sheet and tube. We also cut RHS, PFC, flat bar, unequal angle and EA profiles. Mild steel laser cutting works well for simple parts and detailed shapes.

Do you only work with mild steel?

No. Along with mild steel laser cutting, we also cut stainless steel, aluminium, brass and copper. Our machines suit many materials and thickness ranges.

Is Australian-made steel available?

Yes. We use Australian-made TRU-SPEC® Laser Plate from BlueScope. This gives steady quality and strong performance for all mild steel laser cutting jobs.

Can you handle big orders or repeat parts?

Yes. Our TRUMPF machines run fast and produce the same result each time. Mild steel laser cutting is ideal for batch work and repeat runs.

How accurate is your cutting?

Our machines cut with very high accuracy. The laser stays steady, so every part comes out clean and consistent. This accuracy is one of the biggest benefits of mild steel laser cutting.

How do I get a quote?

Send your drawings or project details through our quote form. We will respond with pricing and timeframes.

Contact Us Today!

Ready to learn more about our services?

We will work hard to provide you with the best service possible, and we guarantee that you will be satisfied with the end product.