32 Harley Crescent Condell Park NSW, 2200 Australia

HYGRADE LASER PROFILING

LASER CUT BRASS & COPPER

For over 30 years, Hygrade Laser Profiling has delivered precision cutting for brass and copper with unmatched accuracy and efficiency. We produce high-quality results, from intricate designs to complex projects, ensuring clean edges and superior finishes every time. You can also explore our wider range of

laser cutting services in Sydney on our main page.

Different Technology We Use

Cutting brass and copper is no longer a challenge. With our TRUMPF TruLaser 5030 Fiber and 3000 Fiber, we deliver high-quality, precision cuts with speed and efficiency. These advanced lasers handle both thin and thick materials, ensuring detailed results tailored to your needs. Beyond copper and brass, our technology also cuts aluminium, stainless steel, and mild steel with exceptional accuracy.

Trumpf TruLaser Tube 3000

TRUMPF TruLaser Tube 3000 Cutting Capabilities

| Material | Maximum Cutting Thickness |

|---|---|

| Mild Steel | 8mm / 8mm |

| Stainless Steel | 6mm / 4mm |

| Aluminium | 6mm / 4mm |

| Brass | 3mm / 4mm |

| Copper | 3mm / 4mm |

MATERIAL RANGE

STANDARD

Rectangular Profile

RHS Min

152mm x 15mm

Parallel Flange Channels

PFC Max

150mm x 75mm (Max Weight 20 KGs per Metre)

Flatbar

Flatbar Max

160mm Wide

Unequal Angle

UA Max

125mm x 100mm

We also laser cut EA (Equal Angle)

Trumpf L3050 5kw

- Tube Processing (Rotolas).

- 1500mm x 3000mm Cutting Area.

TruTops Boost

Our TruLaser 5030 Fiber is powered by TRUMPF’s TruTops Boost.

Unlike other operating systems, TruTops Boost is unbeatably fast and easy to use with all calculations occurring automatically.

TruTops Boost Advantages:

- Time savings and fewer clicks, resulting in higher productivity.

- Simple NC programming.

- Recurring routine work is taken over by the system.

- Automatic solution suggestions.

- Optimal material utilisation.

- Improved nesting result.

- Fast interactive execution of production-specific optimisation.

WHAT CLIENTS SAY ABOUT OUR BRASS & COPPER LASER CUTTING SERVICES

HYGRADE CAN MANUFACTURE YOUR NEXT PROJECT.

Brass & Copper Laser Cutting FAQs

What is brass laser cutting?

Brass laser cutting uses a focused laser beam to cut brass with high accuracy. It gives smooth edges and clean shapes with very little heat on the metal.

What is copper laser cutting?

Copper laser cutting follows the same process but uses settings suited to copper. This gives clear, steady cuts without damaging the material.

How thick can you cut brass and copper?

We cut brass and copper up to 10mm with our TRUMPF TruLaser 5030 Fiber machines. We also cut thinner sheets for detailed work. Our brass laser cutting and copper laser cutting setups handle many project types.

Why use laser cutting for these materials?

Brass and copper reflect light and can be hard to cut with older machines. Modern lasers cut them cleanly with less heat and more accuracy. This makes brass laser cutting and copper laser cutting reliable for both simple and complex parts.

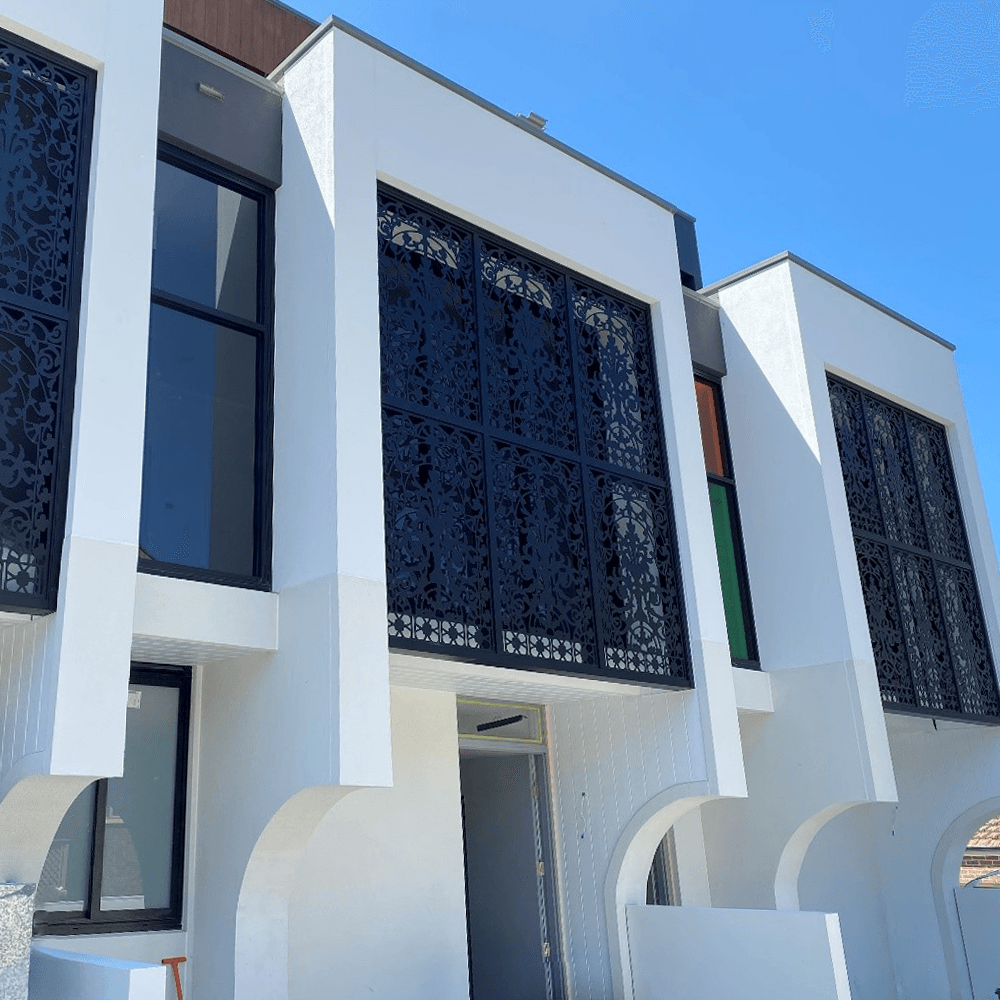

Do you cut detailed patterns and fine shapes?

Yes. Our machines produce sharp edges even on small designs. Both brass laser cutting and copper laser cutting work well for signs, artwork, parts, screens and other detailed jobs.

Can you cut tubes and profiles?

Yes. We cut flat sheet, tube and many profiles. This includes RHS, PFC, flat bar, unequal angle and EA. Our tube laser machines give clean results for both brass and copper.

Do brass and copper require special settings?

Yes. Brass and copper react differently to heat and reflectivity. Our TRUMPF Fiber machines use stable, high-power settings that reduce heat marks. This gives more consistent results in both brass laser cutting and copper laser cutting.

Do you work with other metals too?

Yes. We also cut aluminium, stainless steel and mild steel. Our shop uses advanced TRUMPF machines for all materials.

Is the finish clean enough for visible work?

Yes. Brass and copper parts come out smooth and clean. Most pieces need little to no extra work after cutting. This is one of the biggest benefits of brass laser cutting and copper laser cutting.

Can you handle large production runs?

Yes. Our machines run fast and stay accurate. We can produce one-off parts or large batches with steady quality.

How do I supply my files?

You can send DXF, DWG or other compatible files through our quote form. We also accept hand sketches if you need help setting up your job.

How do I get pricing?

Send your drawings or project details, and we will reply with a quote. Pricing depends on material thickness, quantity and the complexity of the cuts.

Contact Us Today!

Ready to learn more about our services?

We will work hard to provide you with the best service possible, and we guarantee that you will be satisfied with the end product.