32 Harley Crescent Condell Park NSW, 2200 Australia

Hygrade Laser Profiling

Your one-stop job shop in Sydney for everything from laser cutting to CNC machining – every laser cutting service you need to bring your idea to a reality, all under one roof.

INDUSTRIES WE SERVE

We provide high-quality laser cutting, tube processing, machining, bending, rolling, and welding for a range of industries. Our precision-cut components support:

Our expertise ensures durable, high-performance components for industries requiring strength, accuracy, and compliance.

We are Sydney's #1 Laser Cutting and Manufacturing Specialists

EVERYTHING TO GET YOUR JOB DONE

WHAT WE DO

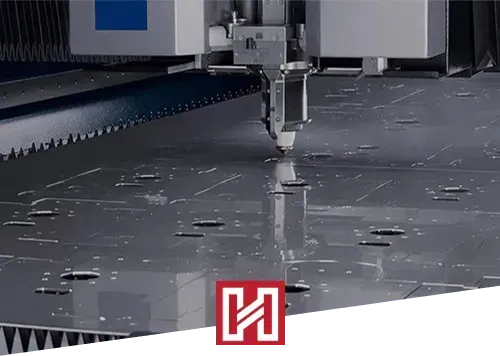

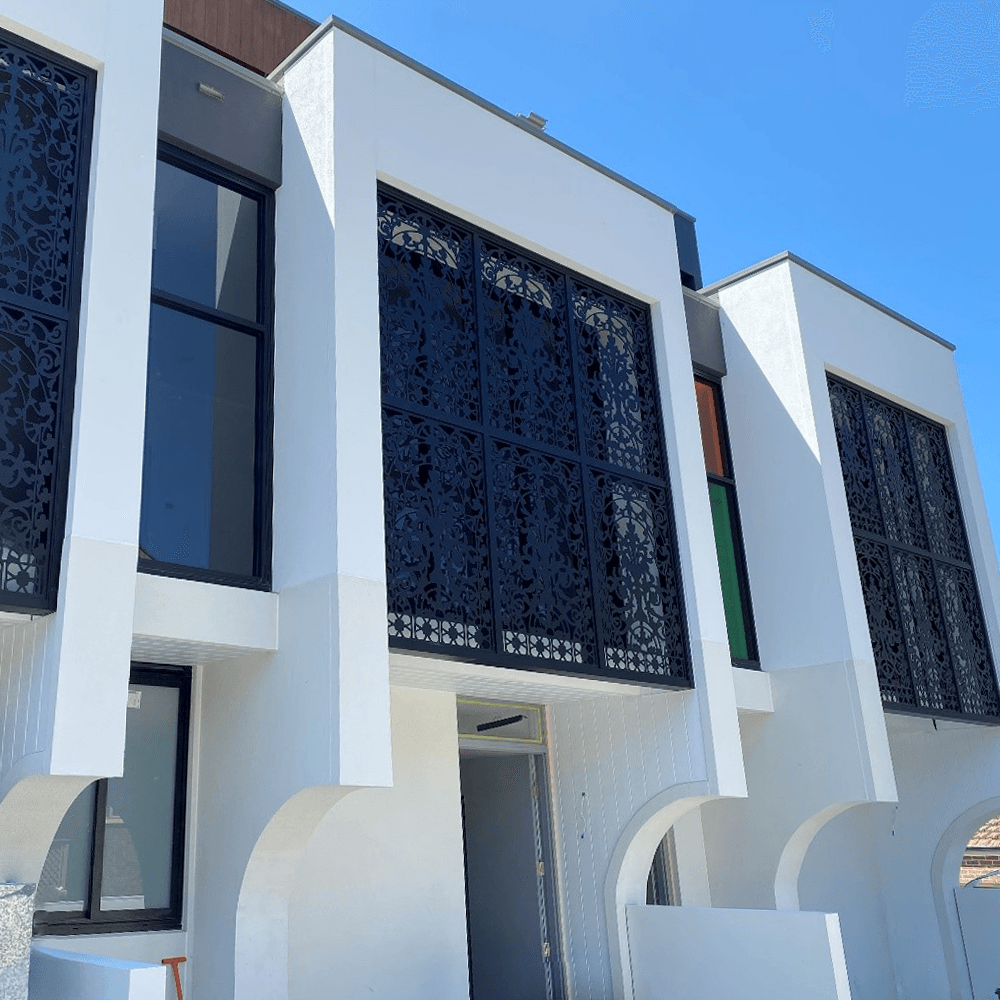

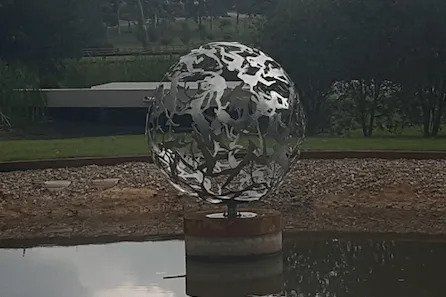

LASER CUTTING

We laser cut steel, aluminium, brass, copper and other materials of varying material thickness levels. We don't cut plastic or timber.

Laser TUBE PROCESSING

Using the flexibility afforded by lasers, raw tubing can be loaded into our laser tube cutter and the finished parts can be sent directly to the final assembly.

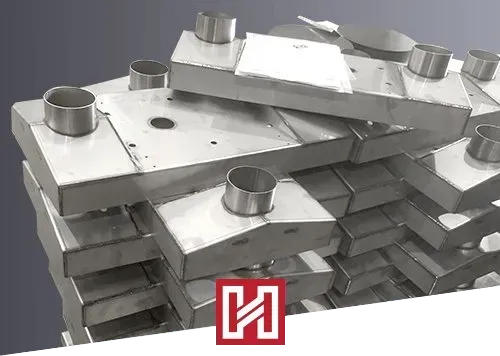

BENDING/FOLDING

Our CNC Hydraulic Press Brakes will take care of all of your folding and bending requirements.

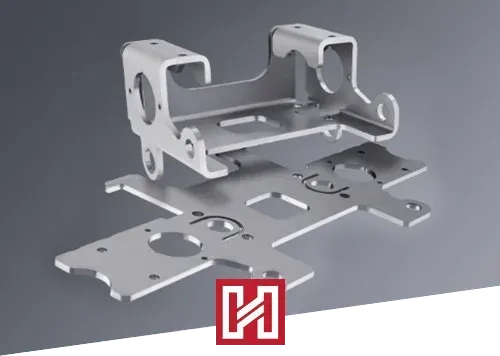

MACHINING

We offer a complete CNC machining service including Tapping, Countersinking and Milling.

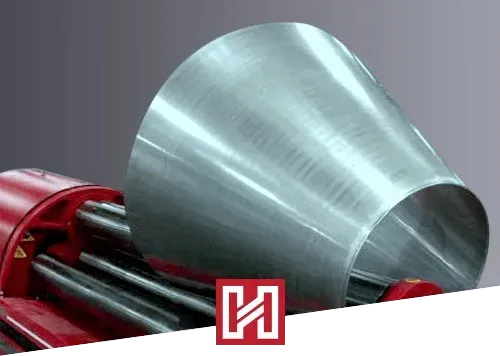

ROLLING

Hygrade has the technology to provide ring rolling, roll bending, roll forming, profile rolling, and controlled rolling.

WELDING

Contact the experienced team at Hygrade Laser Profiling for your TIG and MIG welding needs.

FIXINGS AND FASTNERS

Hygrade provides quality in-house fixing and anchoring solutions for all fastening needs into both ferrous and nonferrous metal components.

PRODUCT DESIGN

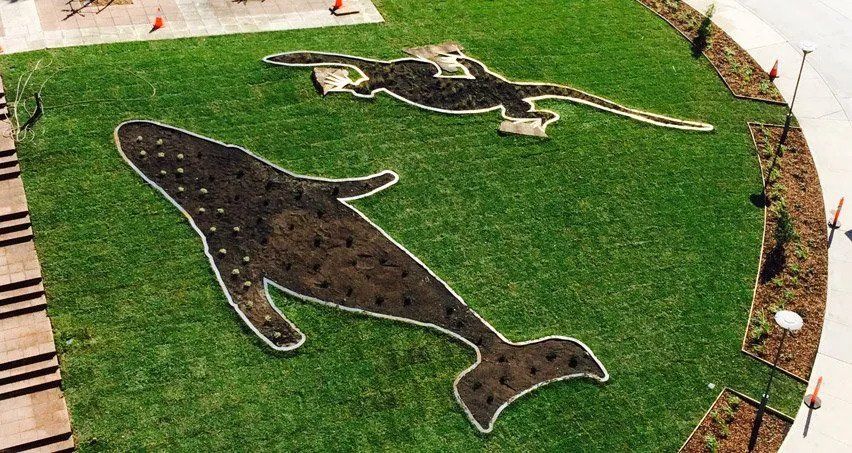

Build your ideas into a product with Hygrade. From design and prototyping through to manufacturing, our professional laser cutting specialists are here to help you create the best projects.

In Business Since 1989

Established in 1989, Hygrade Laser Profiling has been providing professional laser cutting in Sydney for more than 30 years. We use advanced laser cutters to process stainless steel, mild steel, brass, and copper. We don't laser cut plastic or timber. Our Sydney laser cutting company also offers CNC machining, bending, folding, and welding.

WHY US?

OVER 30 YEARS EXPERIENCE

Hygrade Laser Profiling has been a trusted name in Sydney laser cutting for over 30 years. Our wide breadth of experience allows us to solve cutting and manufacturing challenges with speed and accuracy.

Exceptional Product Quality

Our Sydney laser cutting work is known for its quality. We cut stainless steel, mild steel, brass, and copper to your specifications.

Better Turnaround Times

We use advanced laser cutters with fast processing speeds. This helps us reduce lead times and deliver work quickly.

Complete Range of Services

Alongside laser cutting, we offer machining, bending, rolling, and welding. We provide everything you need in one place.

State-of-the-art Equipment

We use modern laser cutters and CNC machinery to produce consistent, high-quality results.

Commitment to Quality and Service

We take pride in our work and focus on precision and professionalism. Our goal is to remain a leading Sydney laser cutting service provider.

Stunning

Product Design

At Hygrade, our highly skilled team can turn your ideas into real products. We support you from design through to manufacturing using advanced laser cutters.

WHAT CLIENTS SAY ABOUT OUR Sydney LASER CUTTING SERVICES

HYGRADE CAN MANUFACTURE YOUR NEXT PROJECT.

SYDNEY LASER CUTTING FAQS

What is laser cutting?

Laser cutting uses a focused beam to cut metal with accuracy. It produces clean edges and handles detailed shapes without physical contact.

How does the process work?

The laser follows a programmed path and melts or vaporises the metal. This creates steady cuts, smooth edges, and very little waste.

What materials do you cut?

We cut stainless steel, mild steel, aluminium, brass, and copper. We don’t cut plastics or timber.

How thick can you cut?

Thickness depends on the material and machine. Send us your project details and we’ll confirm what we can cut.

How fast is your turnaround?

We work efficiently and aim to complete projects as quickly as possible. For urgent jobs requiring fast turnaround, contact us and we’ll advise what options are available.

Do you offer delivery or pickup?

Yes. We can arrange delivery across Sydney, or you can collect your order from our workshop.

Do you offer more than quality laser cutting services?

Yes. We also provide computer numerically controlled (CNC) machining, bending, rolling, welding, and support with product design and prototyping.

Can you help with custom designs?

Yes. You can send us your own files, or our team can help prepare your design. We support simple parts, detailed shapes, and decorative metalwork.

What industries do you work with?

We support the laser cutting needs of industries like construction, architecture, transport, engineering, manufacturing, public space projects, and creative work like signage and decorative screens.

What are the advantages of laser cutting?

Laser cutting offers high accuracy, clean finishes, low waste, and the ability to produce complex shapes.

Where are your services available?

We are based in Sydney and work with customers across NSW. We also manufacture and ship Australia-wide.

Is laser cutting safe?

Yes. Our workshop follows strict safety practices, protective gear, and regular equipment maintenance.

What file types do you accept?

Send us your drawings or digital files. If you’re unsure about the format, our team can guide you or help prepare the file.

Do I need to prepare my files a certain way?

Simple, clear layouts work best. If you need help preparing cut lines or design elements, our team can assist.